1. keep your systems in operation by shortening the lead times for spare parts

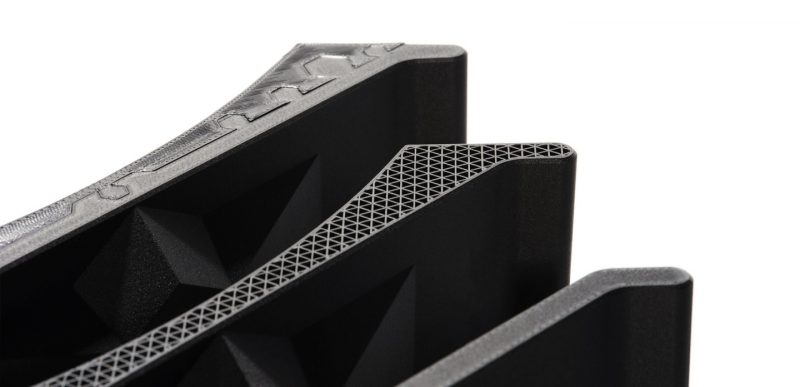

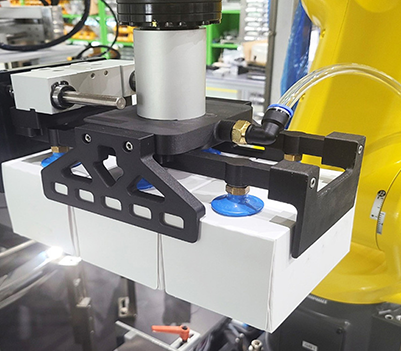

Wear and tear on manufacturing equipment leads to maintenance and downtime, which affects production efficiency. 3D printing is a cost-effective alternative for producing replacement components such as brackets, pushers and EOAT on demand.

Think of the pushers in the packaging lines that are used for diverting, sorting, rejecting, inserting, feeding and changing lanes. Replacement pushers can be 3D printed in-house in a matter of hours, resulting in significantly shorter lead times and lower part costs compared to outsourced production. This eliminates the need to wait for shipping and part development cycles, and the production line can be back up and running immediately to avoid costly downtime.

3. more sustainability and lower costs in the supply chain

Disruptions in the global supply chain have led to delays, bottlenecks and higher costs in the procurement of parts, impacting manufacturers' ability to meet demand and achieve their sales targets.

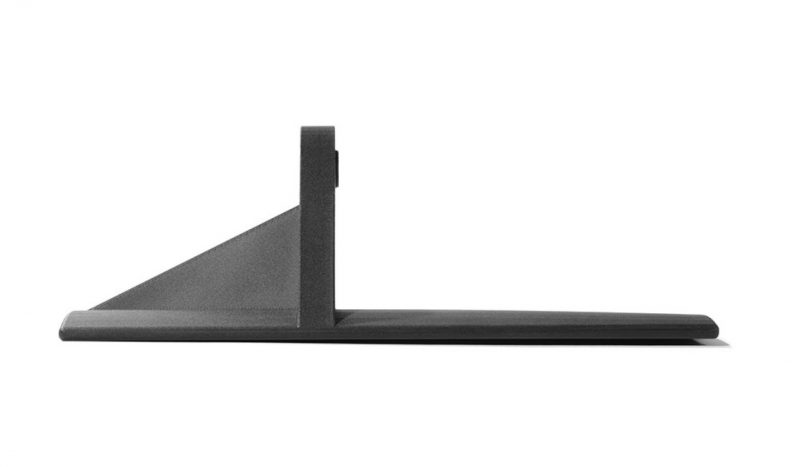

For example, the procurement and manufacture of a small component such as a conveyor belt guide, which uses compressed air to transport products along the production line, currently takes up to 12 weeks. However, manufacturers print the parts within hours or days, restoring the original productivity of the production line.

Additive manufacturing reduces the environmental impact of complex supply chains by decentralizing the procurement process. When an assembly line needs to be retooled for new products, manufacturers simply print a component on the factory floor. Introducing a digital 3D printing platform on the factory floor reduces manufacturers' reliance on distant suppliers and cuts excessive spending on materials, transportation and resources - all of which contribute to a more efficient and sustainable manufacturing process.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar