Discover the FX10: The first industrial printer for metals and composites

The FX10 was launched as a next-generation composite printer in fall 2023. They promised modularity, but didn't say what modularity meant.

Now we can clarify that. The modularity we promised was the metal FFF capability, making the FX10 the first industrial printer capable of printing composites and metal parts. The FX10 was designed from the ground up to offer customers this dual capability. In this blog post, we'll talk about what it took to achieve this goal and what it means for you as a potential user.

Process comparison: composite material and metal

Before we talk about FX10 itself, we should explain the two complementary processes it combines for printing metal and composite materials: FFF+CFR and Metal-FFF.

Markforged's composite printers use a dual process: Fused Filament Fabrication (FFF, also known as FDM) and Continuous Fiber Reinforcement (CFR). FFF is an industry-standard 3D printing process in which thermoplastic-based filaments are heated and extruded in individual layers through a nozzle to create a part. CFR is a secondary process that allows FFF 3D printers to reinforce parts with continuous fibers. CFR uses a second extrusion system for long-strand continuous fibers. The continuous fibers are applied in layers, replacing the FFF infill. The resulting parts are significantly stronger (up to 10 times stronger than any FFF material) and can replace aluminum parts in the application.

Markforged has developed a process known as Metal FFF, which allows metal parts to be printed in near-net form without the use of metal powder. Metal FFF is a three-step process, described below.

- Press: A specialized FFF printer prints a filament made of polymerized metal powder (similar to MIM raw material). During the printing process, the polymer is melted and extruded, carrying the metal powder along with it. Parts are printed with rafts and supports made of the same material, which are separated from the part when needed by a ceramic release material printed through a second nozzle. The resulting "green parts" are enlarged by approximately 20 µm to account for shrinkage later in the process.

- Giving birth: The green parts are immersed in a debinding solvent that dissolves the polymeric binding material. After debinding, the parts are referred to as "brown parts."

- Sintering: Brown parts are sintered in a special furnace, turning them into solid metal parts. During printing, the part shrinks by approximately 20 µm.

Metal parts printed with Metal FFF are almost dimensionally accurate and usually have an open-cell filling.

Bridging the gap

To build a metal and composite FFF printer, our engineers had to overcome an existential stumbling block—the fundamental incompatibility between polymer filaments and early metal filaments. Polymer filaments are simple, but they have one requirement: closed material paths to limit moisture exposure. Early metal filaments had the exact opposite problem: they were so brittle that they required special treatment to even print, including an unsealed tube between the spool and the print head. This issue made developing a dual-capable device nearly impossible.

To resolve this incompatibility, we went back to the drawing board with metal FFF filaments. Instead of using brittle filaments very similar to the raw material used in metal injection molding, we formulated our own polymer binder optimized for 3D printing. The resulting "flexible" filaments were easier to handle, prevented nozzle jams, and, most importantly, could be fed through feed tubes without breaking. Our first flexible filament was Copper (released in 2020). Over the past two years, we've reissued three of our most popular steels (17-4PH v2, H13 v2, and D2 v2). 316L will be launched next year once the FX10 metal capability comes online.

Flexible metal filaments were the most important technical innovation of the FX10.

Although flexible filaments solved the fundamental problem of building a dual-mode system, our engineers still needed to find a way to build a reliable system for printing two very different media. To that end, they built the most modular machine we've ever developed.

How it works

When developing FX10, we took into account that metal and composite filaments require completely different hardware to move the material from the spool to the part. To accommodate this, we made key parts of the printing machine interchangeable (see below).

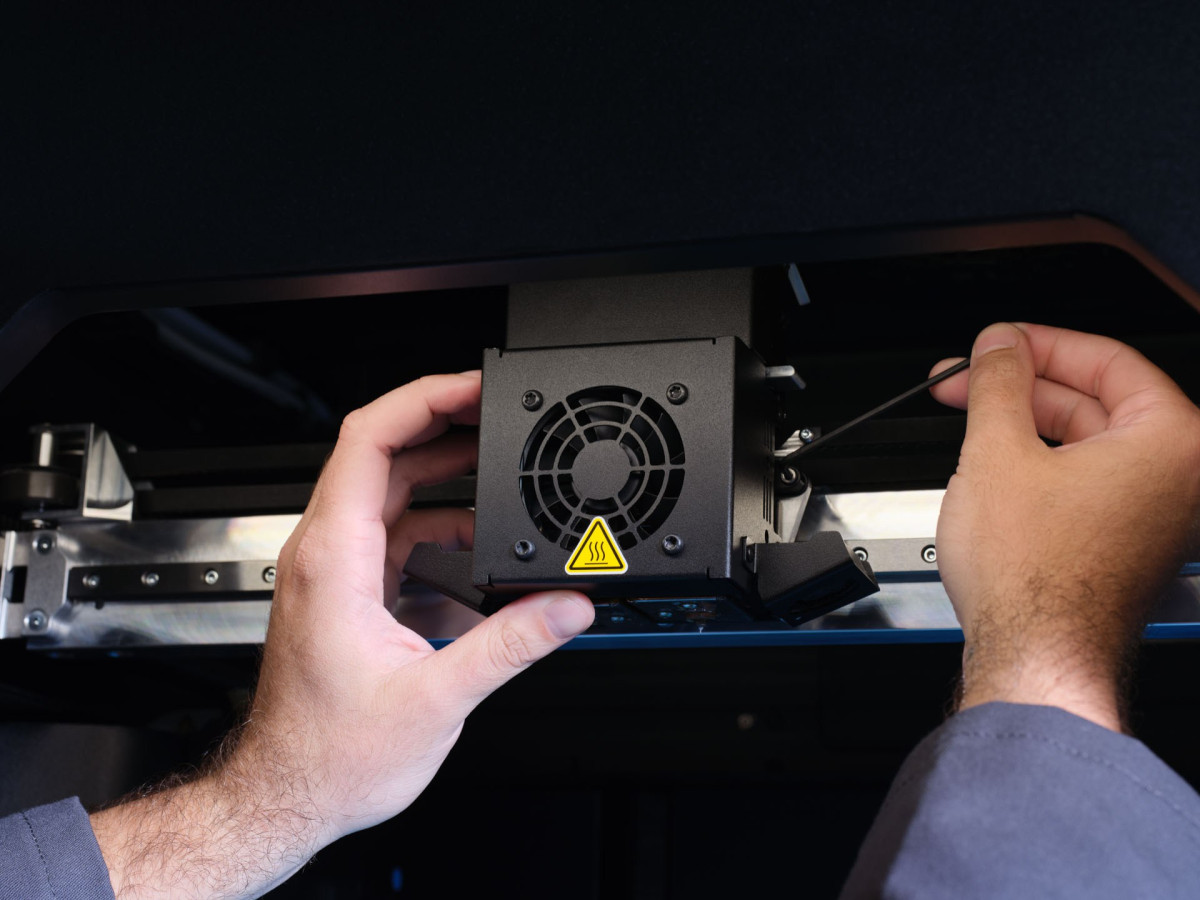

- Print head: Composite and metal each have their own print head—both with two nozzles. The composite print head has a plastic nozzle and a fiber nozzle, while the metal print head has a nozzle for metal filament and a nozzle for ceramic release material. The print head can be removed and replaced with just two screws.

- Material guide block: The material guide block is located at the rear of the machine and houses four feed tubes (one from each spool compartment). With the composite block, these tubes feed into a single outlet to supply the print head. With the metal block, they feed into two outlets: one for metal filament and one for ceramic release material. The block can be replaced by removing a single screw.

- Material hoses: Special material hoses ensure that no cross-contamination occurs between metal and composite filaments.

The FX10 printhead can be replaced by removing just two screws.

In addition to the three components of the printing unit, several additional parts must be replaced, including the print sheet, the flushing tank, and the spool holder. The complete changeover takes about 15 minutes, after which the machine performs a calibration routine that takes about an hour.

With the FX10, you can fully transition between metal and composite printing in less than two hours. The printed metal parts still need to be washed and sintered, using the same auxiliary machines offered by Markforged.

The final product

The FX10 is available in two configurations: Composite and Metal + Composite. The Composite configuration comes with the printer, while the Metal + Composite configuration comes with the printer (in the Composite configuration, the FX10 Metal Kit, the Wash-1, and a Markforged sintering furnace). A user purchasing only an FX10 with composite can acquire metal capability by purchasing the Metal Kit, the Wash-1, and a sintering furnace. A customer with existing Markforged metal FFF capabilities (via the Metal X) can purchase an FX10 with a Metal Kit to expand their metal capabilities.

The FX10 is compatible with all of our existing flexible metal filaments: 17-4PH v2, copper, H13 v2, and D2 v2. In addition to the existing materials, we're releasing a new filament exclusively for the FX10: 316L. This highly corrosion-resistant stainless steel is used in the food and beverage, marine, and other industries.

FX10 metal and composite applications

As the first FFF printer capable of printing both composites and metal, the FX10 is the first device capable of covering the entire spectrum of manufacturing applications. Metal and composite printing complement each other perfectly, leveraging each other's strengths.

Composite is characterized by

- Large parts: With metal FFF, part dimensions are limited by the sintering process. For parts larger than 15 cm, composite printing is usually a better solution.

- Compliance with requirements: Composite and plastic parts can be designed to yield or flex under load, which is ideal for many devices.

- Non-painful surfaces: Composite materials are contact-free, which is essential when handling sensitive materials.

- Cost-effective and fast: Compared to the 3-step FFF process for metal, composites can be manufactured faster and more cost-effectively than metal parts.

- Tighter tolerances: While metal can be post-processed, composite printing machines offer much tighter tolerances than metal.

Metal is characterized by

- Strength and hardness: While composites are strong, stainless steels and tool steels offer strength that can only be achieved with metal. Likewise, metals are orders of magnitude harder than printed composites, and some can be further strengthened.

- Heat resistance: For parts used in environments above 200 ºC, metal is the only option.

- Wear resistance: Metal is not only hard (and hardenable), but also offers far better abrasion resistance for parts subject to repeated stress.

- Workability: Metal parts can be machined with tight tolerances or mirror finishes.

- Thermal and electrical conductivity: Copper offers unique thermal and electrical conductivity for parts with special requirements.

Composites solve many problems, but sometimes you just need metal.

These highly complementary strengths come into play in three ways: shared applications, unique applications, and hybrid applications.

For some applications, such as end-of-arm tooling, composites and metal excel for different reasons. Composite EOAT can be non-contact grippers and vacuum tools, while metal EOAT are typically production grippers used in high-volume manufacturing. When both technologies are available, the application range expands to include a wider variety of parts.

In other cases, a specific property of composites or metal allows the engineer to access a specific application. A good example of composites is factory tools: the numerous brackets, fixtures, guides, and jigs required for a production line to run effectively. These parts are essential but benefit from the low cost and speed of composite printing. Simply put, they don't have to be metal. On the metal side, high-temperature tools like soldering fixtures can only survive if they are printed in metal.

Finally, hybrid applications allow engineers to leverage the complementary advantages of metal and composite materials in a single assembly, creating highly optimized tools with enhanced performance. A perfect example is end-of-arm tools with composite tool bodies and metal wear pads. In these tools, the composite tool bodies are cost-effective, strong, and quick to produce, while the metal wear pads provide hardness and abrasion resistance. By using both materials, a tool can be customized for a specific application in ways not possible with any other manufacturing technology.

The quintessence

The FX10 was already an excellent, class-leading machine as a pure composite machine. The addition of metal makes it a truly transformative manufacturing tool: the first FFF machine capable of credibly producing metal and composite parts on the factory floor. We're convinced this is the most versatile tool for your factory floor. If you'd like to learn more, talk to one of our 3D printing experts.

Hinterlasse einen Kommentar