It's finally available!

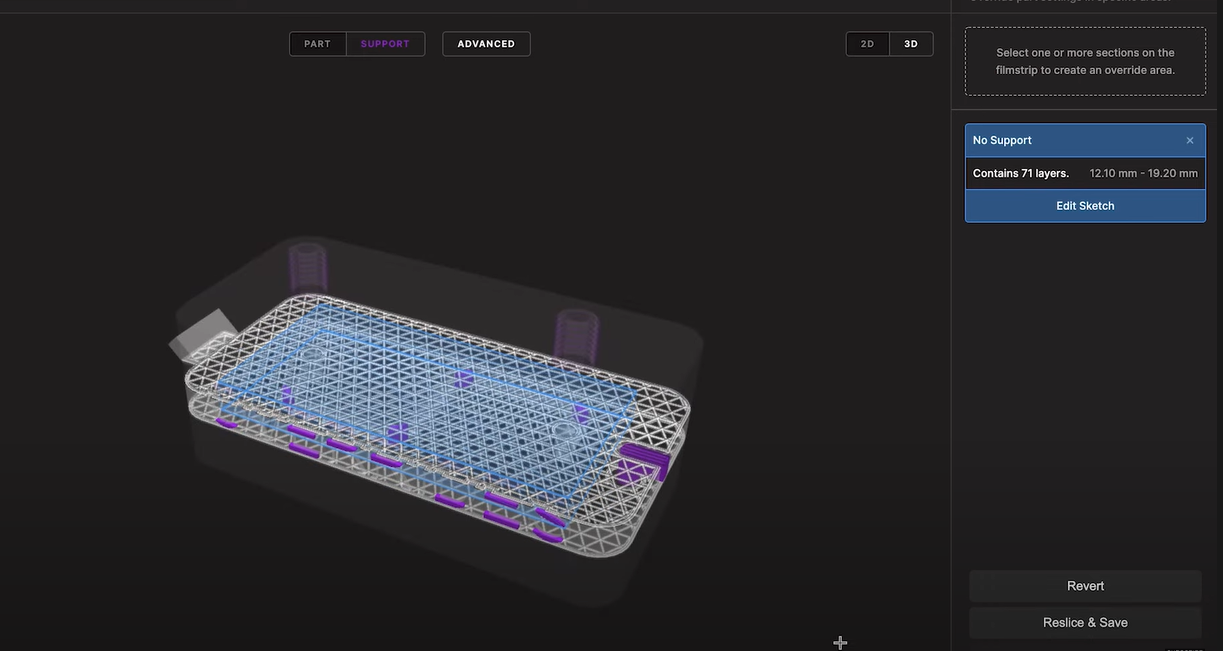

One of the most requested features in our Eiger software was the ability to select a customizable support structure. You can now freely design the support structures of your components in the Eiger software.

In sub-areas of geometries, the structure can now be removed and added as desired.

This saves both material and time, especially when it comes to reworking delicate support structures that are not absolutely necessary.

For example, small cross-holes that were previously supported and difficult to free can now be freed from the support structure in advance in the Eiger software.

We have shown you a short application in the video.

If you have any questions about this feature, please contact our support colleagues.

When 3D printing parts with overhangs, support material plays a critical role in ensuring the parts are manufactured as intended. After printing, the support material is typically lightly removed before the part is used. If the use of support material is enabled when slicing a part, Eiger's default settings automatically generate supports optimized for most parts. However, some parts contain features such as internal channels, small overhangs, or threads that can be problematic with support material.

We've heard from our customers that they'd like the control and flexibility to decide which areas of a part should and should not be supported. In response, we're now announcing that our Eiger 3D slicing and printing software includes a new support material override feature, making it simple and easy to select customizable support structures.

Override default settings when using supports for a part

Specify areas where supports should be created or blocked

Request a DEMO component now!

See for yourself how strong the components are.

Example of a component with internal channels and threads that without individually customizable support structure.

Example of a component with internal channels and threads that with individually customizable support structure.

In summary:

With the customizable support structure in Markforged Eiger software, you can:

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar