Profitably leveraging the advantages of 3D printing technology can reduce manufacturing costs. With virtually unlimited application possibilities for plastic and metal printers, modern manufacturing companies have no shortage of opportunities.

"Over time, manufacturing companies have had to adapt to survive, and the 2020s will be no different," writes Ian Weston, Managing Director at Mark3D UK. Management's constant demand to identify and reduce costs means today's engineers must be more adventurous and creative to achieve valuable cost savings.

Many in the manufacturing industry, especially in engineering, believe that "the easy wins are long gone." However, I'm not so sure. Over the past five years, we've seen a number of agile, entrepreneurial high-tech firms either launch or spin off from their current positions to offer today's engineers a host of advanced technologies that can help reduce costs. Known as "Industry 4.0," they're introducing a range of offerings, from design automation and iteration to production monitoring software with logic-based real-time decision-making to good old-fashioned 3D printing, considering it's been around for about 30 years.

The market is moving very quickly, and 3D printing for engineering has improved tremendously in recent years. The technology now offers engineers affordable printers with stable materials and reliable results, yet it often struggles to be taken seriously in the conference room. While early 3D printers played a significant role in raising awareness of the technology, they had an equally negative impact due to the objects people wanted to print with them. Green men and game characters fail to cut through the technical boardroom floor.

There is a possibility of a significant Return on Investment (RoI), if the production engineers know where to find it. Simply borrowing a printer from the design office and expecting immediate cost savings isn't realistic. Printers in the design office use different materials and technologies than those used by engineers. Printing-savvy engineers know that 3D printing is far more valuable to businesses outside the design office than inside, with return on investment typically achieved in about three months.

Request a DEMO component now!

See for yourself how strong the components are.

A solution for every engineer!

Imagine you are JoeJoe is a great engineer who takes great pride in his work, but he's very busy. He only has the budget for essentials to keep his factory running and to support his colleagues with technical items. He dreams of speeding up production with new fixtures, making machines run faster by reducing the weight of metal parts, and reducing the cost and lead times of outsourced components. There are many things Joe knows he should fix, but they're all on an ever-growing wish list he'll never tackle.

There are thousands of "Joes" in the world. While some have embraced the new light and invested in full-fledged 3D printers, many are too busy, are prevented from investing by their business owners, or simply don't understand their options. However, 3D printers that print stable base materials and, if needed, a second continuous-fiber filament, such as carbon fiber, can be purchased for less than the cost of a pickup truck.

Find the right 3D printer!

Modern 3D printers produce plastic parts that are stronger than aluminum, weigh significantly less, and cost a fraction of the price. The potential applications are virtually endless for anyone who invests in the technology. Today, you can print robust robot grippers and reduce the weight of the part by a third. This weight reduction allows the robot to increase its payload by the same amount or move faster during the process, depending on the operator's preference.

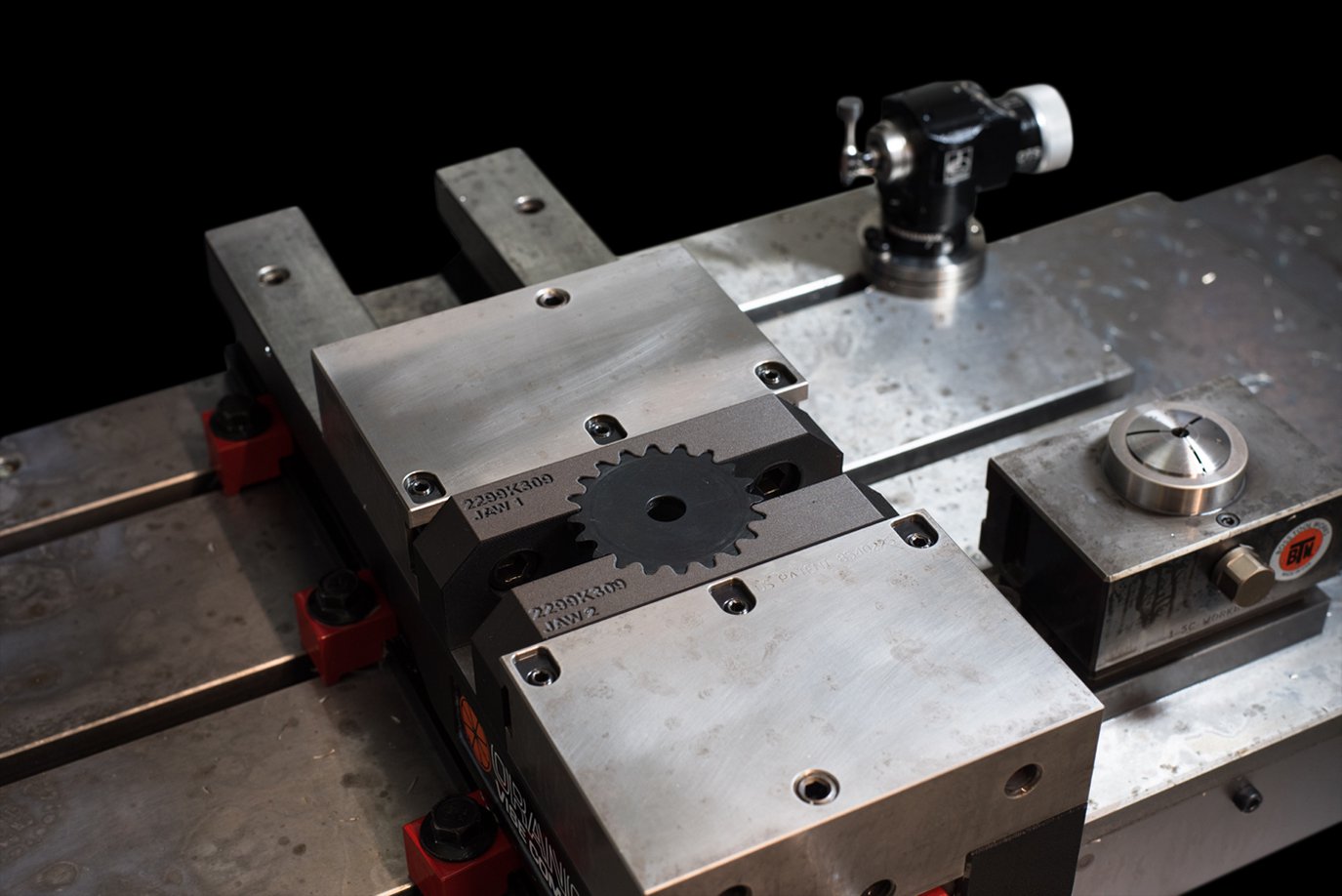

Machining fixtures that can withstand the harsh environments found in CNC machine tools and drilling fixtures can be printed in a fraction of the time required to subcontract. These fixtures are as accurate as the "traditionally" manufactured ones currently in use.

Entry-level machines, known as desktop printers, are very popular with many organizations that purchase multiple systems. These machines offer the full range of materials needed by today's engineers. They use a 240V plug and operate 24/7 on a desk in the engineering department. Programs can be sent remotely to the printer once an accurate time/cost analysis has been performed using the associated software.

“Imagine a world where centrally controlled design departments print parts on demand in decentralized facilities around the world and local employees assemble them.” – Ian Weston, Managing Director, Mark 3D UK

Larger industrial-style machines now incorporate laser measurement systems for inspecting and automatically correcting parts in the mid-range printing range, providing a constant feedback loop for making necessary corrections. They offer flame-retardant and electrostatic-safe materials for specialty applications and typically produce products that are ten times cheaper than CNC-machined parts. Due to cost, practicality, and logistical advantages, we are now seeing printers appearing in traditional contract manufacturing machine shops as business owners respond to the changing dynamics.

Some new materials

Today, hundreds of examples exist to demonstrate end-use applications. These "fit and forget" applications allow those not in engineering to continue their daily routines without knowing that their mission-critical machine contains printed parts. Due to the volume and quality of new materials, it can be very difficult to distinguish which parts are printed and which are manufactured traditionally.

A number of easy-to-use metal printers have also appeared on the market, costing less than the price of an average CNC machine tool. These printers offer an ever-expanding selection of materials and regular expansions in functionality. The technology is now both affordable and usable by today's average entrepreneur like Joe. It has a very short learning curve and requires no specialized knowledge. Therefore, adoption is expected to grow exponentially. In a very short time, we will see metal printing become commonplace, and the use of hybrid solutions (plastic and metal) in engineering will also advance quite rapidly.

In many situations, traditional manufacturing techniques used for centuries to produce low-volume components can no longer compete. I believe that eventually, every company serious about manufacturing will have a composite 3D printer on its factory roster, and most will add metal after becoming more comfortable with plastic. Engineers will have access to their machines from anywhere in the world and will think nothing of remotely triggering print jobs via a wireless connection. This is truly the beginning of a global transformation of the manufacturing process.

Learn more about applications using composite fiber 3D printing for plastics!

Which continuous fiber is suitable for which application, and how do I correctly design composite fiber 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar