New cooperation with Nippon Gases 🤝

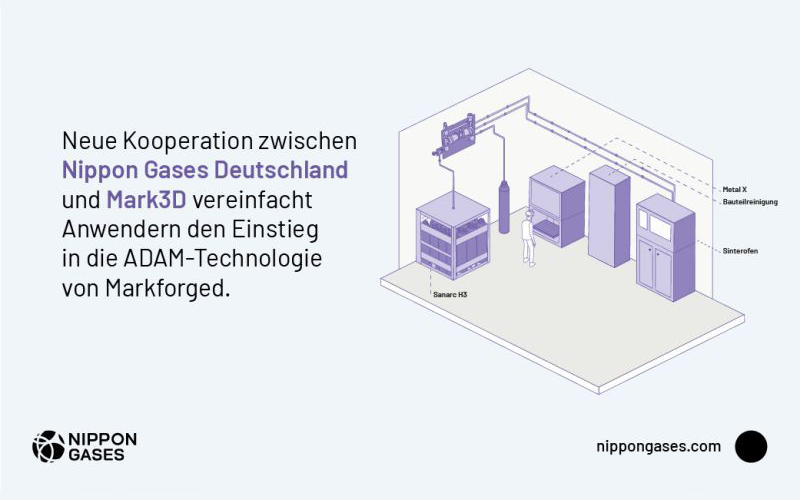

We are collaborating with Nippon Gases with the aim of offering new and existing users a complete package that enables them to safely and reliably additively manufacture highly complex components in a clean environment – using the ADAM (“Atomic Diffusion Additive Manufacturing”) technology developed by Markforged.

Nippon produces a special gas mixture for the Markforged Metal X metal 3D printing system.

The first users are already benefiting from the performance and service of both cooperation partners.

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar