Introducing the Performance Advisor: One click to more solid parts

Robust 3D printed parts are a core hallmark of Markforged and a key reason why companies choose our solutions. Choosing the right print settings in Eiger significantly influences a part's strength, material cost, and print time. simulation provides detailed analyses, but requires a specific use case – which is often unknown.

What if it were possible to maximize the efficiency of a part without defining a specific use case? And what if this optimization were so simple that it could be completely automated?

Firmer parts – automatically

To successfully accomplish this task, we've developed an innovative method for analyzing component performance. This method suggests print settings that will make your parts stronger by a known amount, while minimizing the additional cost and print time.

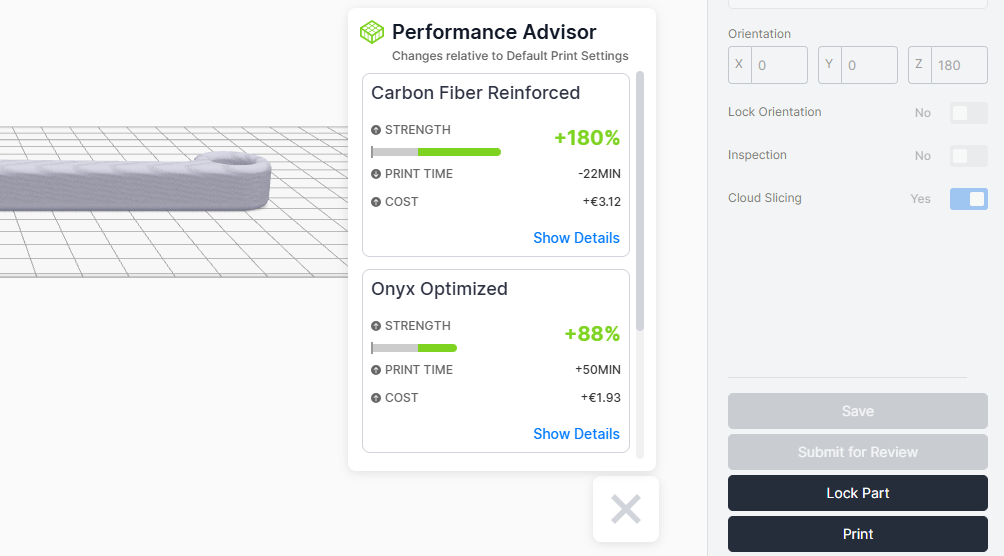

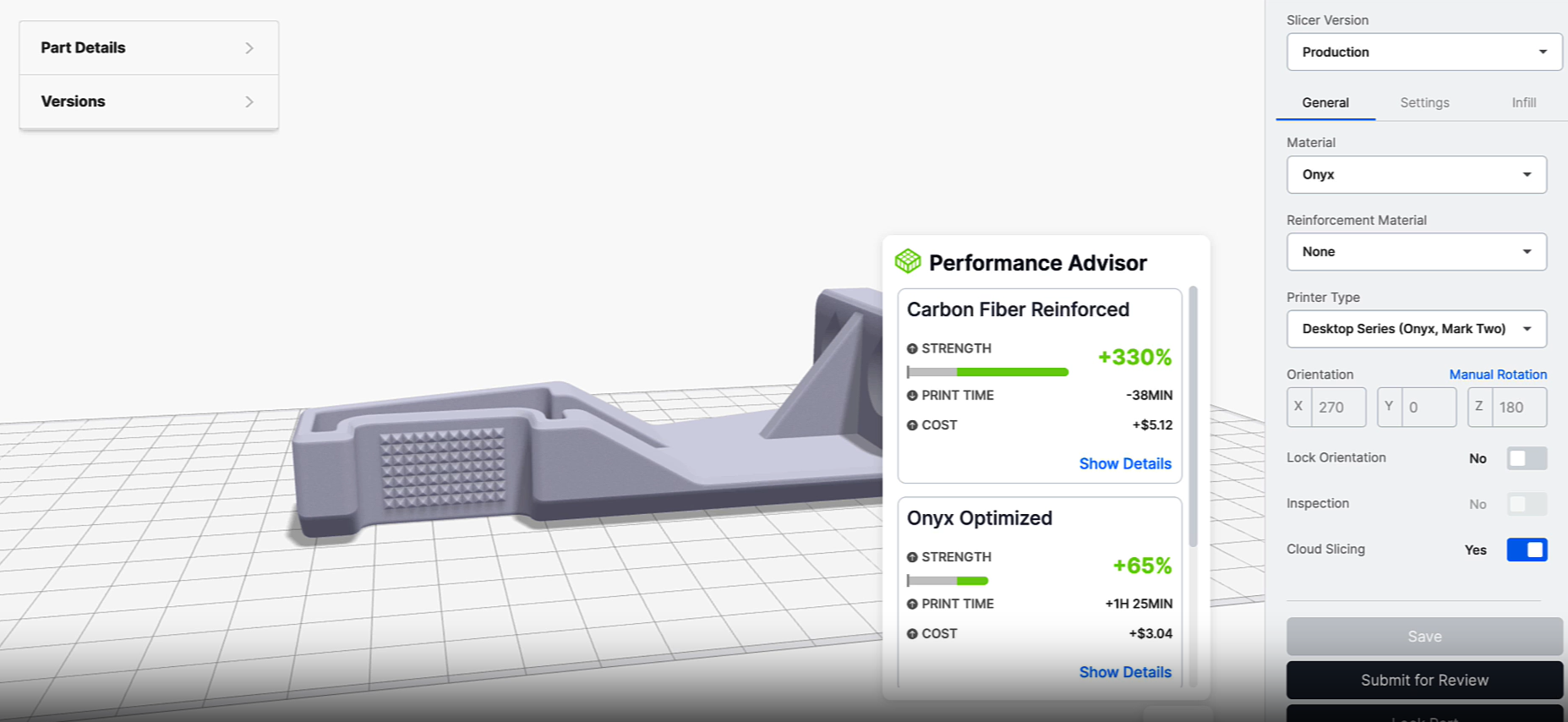

Complete automation is the standout feature of the new feature. No user input is required to achieve results. After saving a part in Eiger, the Performance Advisor automatically analyzes your part and makes recommendations for print settings. These settings improve strength compared to the default settings while keeping material costs and print time low.

As a user, you have the power to decide whether the performance improvement justifies the additional cost and longer print time. You can accept the recommended settings with a single click or ignore them and continue with your Eiger workflow.

Is a part made of 180% that's stronger worth the extra €3.12 in material costs? The choice is yours.

How Additive Manufacturing Works

It's time to delve into the topic and talk about the technology behind Performance Advisor. Our engineers have developed a patent-pending analysis method based on physical principles. This method allows us to perform structural analysis without defining a specific use case. Instead of using a use case, we leverage the natural vibration modes of the part geometry (eigenmodes) to investigate the effects of print settings on part performance.

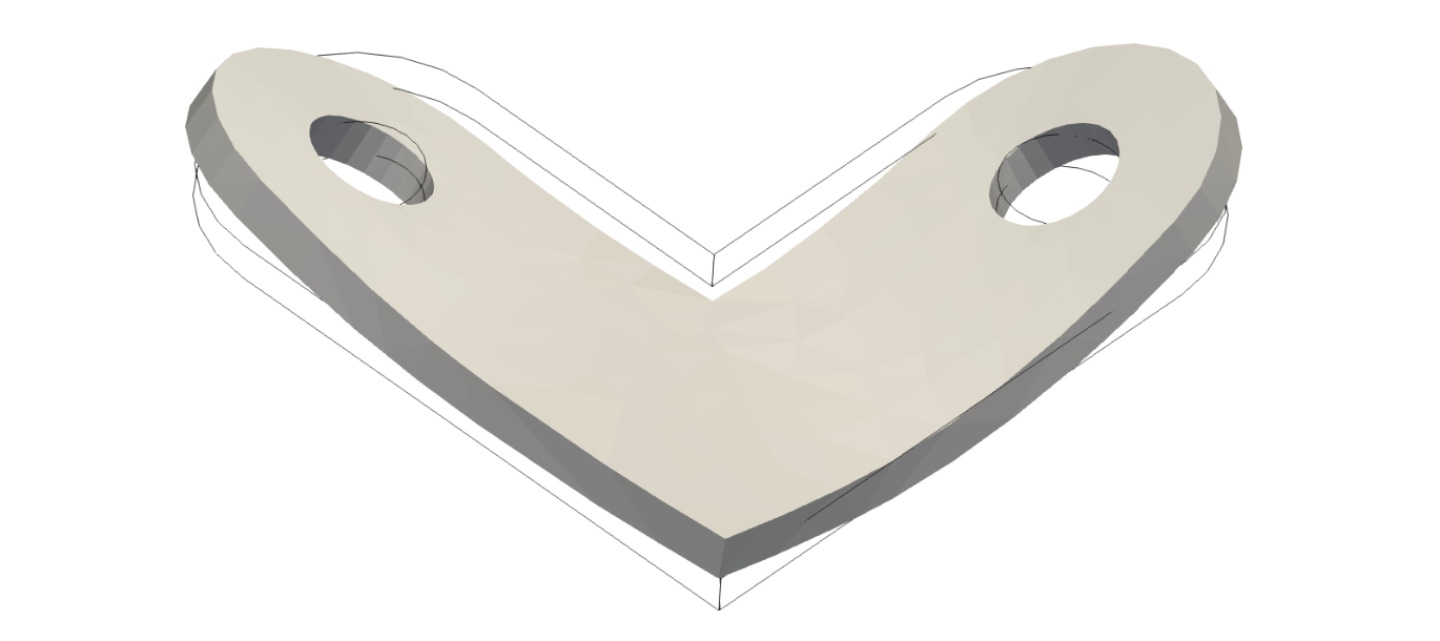

The following figure shows the characteristic shape of the lowest-energy eigenmode for an L-shaped bracket. This is one of the shapes in which this part would naturally vibrate. Imagine printing this part and bending it with your hands. This would likely be the shape you would obtain, as this shape (or mode) has the least resistance to bending. This shape provides the Performance Advisor with information about the areas of the part most susceptible to deformation and stress. Based on this, it finds print settings that reinforce these areas.

The natural mode of vibration (eigenmode) with the lowest energy of a mount. The deformation is greatly exaggerated to emphasize the shape.

To achieve the Performance Advisor's goal, it is important to first calculate the lowest-energy eigenmode. In the second step, a machine learning-based optimization procedure is applied to evaluate the pressure settings based on three variables:

- Material costs

- strength

- Printing time.

High strength, low costs and short printing times achieve optimal printing settings, which are the goal of the Performance Advisor.

I can't see the Performance Advisor – why is that?

If you don't see the Performance Advisor, it's probably because you've hidden it in the past. You can easily undo this by changing the "Hide Performance Advisor in Part Page" option to "Visible" in your Account Settings. Then, whenever you open a file, you should see this icon, which means the Performance Advisor is running:

Next-level strength analysis with simulation

Performance Advisor is a quick and easy way to get more solid parts, especially when the use case is unknown. For applications with a known use case, we recommend using simulation.

Users use simulation to configure a use case that represents the actual loading on the part. A factor of safety is then calculated, which, unlike the Performance Advisor's strength ratio, provides an estimate of the part's strength. Additionally, if the part must meet a specific strength requirement (such as a minimum factor of safety), simulation can optimize the print settings to achieve the desired factor of safety while minimizing material costs and print time.

In conjunction with our finite element solver tailored to the FFF manufacturing process, these additional user inputs result in more realistic and accurate strength estimates than the Performance Advisor.

Simulation takes into account the practical application of a part and provides more detailed information than the Performance Advisor.

The biggest differences between Simulation and Performance Advisor are in the following areas:

1. Use case:

– Simulation is based on a specific use case that influences the results.

– Performance Advisor is application-independent and does not calculate the strength ratio specifically for practical loading.

2. Strength:

– Simulation calculates a safety factor that indicates when a part could fail.

– Performance Advisor indicates the increase in strength of the recommended part compared to the part with standard settings, without taking the load into account.

3. Technology:

– Simulation uses a finite element analysis (FEA) tailored to the Fused Filament Fabrication (FFF) manufacturing process.

– Performance Advisor is based on a patent-pending analysis method that is based on the eigenmode of the part with the lowest energy.

4. Availability:

– Simulation is available in the Digital Forge Advanced subscription. If you're interested, please contact us to learn more about simulation.

– Performance Advisor is available free of charge to all users who have registered a printer in their Eiger company.

Summary:

Performance Advisor is a quick and easy way to achieve stronger parts automatically, without any user input. By eliminating the need to define a use case, all Markforged customers can take advantage of Simulation's tools. This allows you to achieve stronger, more robust parts while maintaining an efficient balance between material costs and print times—all with one click!

Register in Eiger today and try it out!

Hinterlasse einen Kommentar