"Metal FFF excites me because it makes metal 3D printing accessible in unprecedented ways. Companies can stop talking about how AM will change manufacturing and start doing it. As an AM consultant, I've seen many companies develop successful long-term AM strategies: If you're successfully printing polymers and composites, you're already halfway there." -Ross Adams, Global Metal Product Manager at Markforged

Nearly every company using metal 3D printing began its additive manufacturing (AM) journey with polymer printing. After several years of using fused filament fabrication (FFF) printing, they have developed core competencies such as knowledge of design for additive manufacturing (DfAM) and the ability to identify high-impact applications for continuous process improvement.

If you've experienced the many process improvements that can be achieved through polymer and composite printing in your factory, you may be wondering how your business can scale these benefits. A common answer is metal 3D printing.

Below, I'll discuss the reasons why manufacturers with composite 3D printers often add metal AM to their toolbox, when to choose metal over plastics and composites, and how you can get creative with plastic-metal hybrid parts to tackle an even wider range of manufacturing challenges.

On the way to metal: Starting with 3D-printed polymers

After several years of 3D printing polymers, the question that typically arises is, "How can I expand additive manufacturing in my company to realize more aggressive and high-value applications?" While 3D printing polymers is the fastest and easiest way to solve many manufacturing challenges, 3D printing metals is a catalyst for expanding AM to even more high-value applications.

You only use steel when you need steel... but when you need steel, you have to use steel. There is no substitute for the properties that steel offers. Additive manufacturing of metal parts is not only often faster and cheaper, but it also enables the production of geometries that are impractical or even impossible to machine.

Metal 3D printing is often perceived as expensive and complicated, but that's the reality with any type of metal manufacturing process. In fact, in many cases, metal 3D printing is the simplest and most economical way to obtain a metal part. Metal Fused Filament Fabrication (Metal FFF) technology, in particular, makes 3D printing metal parts more accessible than other metal AM technologies, requiring a significantly lower investment (we're talking hundreds of thousands of dollars less) to own and operate. It's also safer and easier to use, as it doesn't require a highly skilled operator. A wide range of materials, such as stainless steel, tool steels, Inconel, and pure copper, can be printed with minimal PPE and safety precautions. This is due to the bonded powder, unlike other metal AM processes that use loose powder.

Once you have internalized the knowledge and advantages of FFF 3D printing of polymers, the transition to FFF 3D printing of metals is seamless: the underlying process is largely the same.

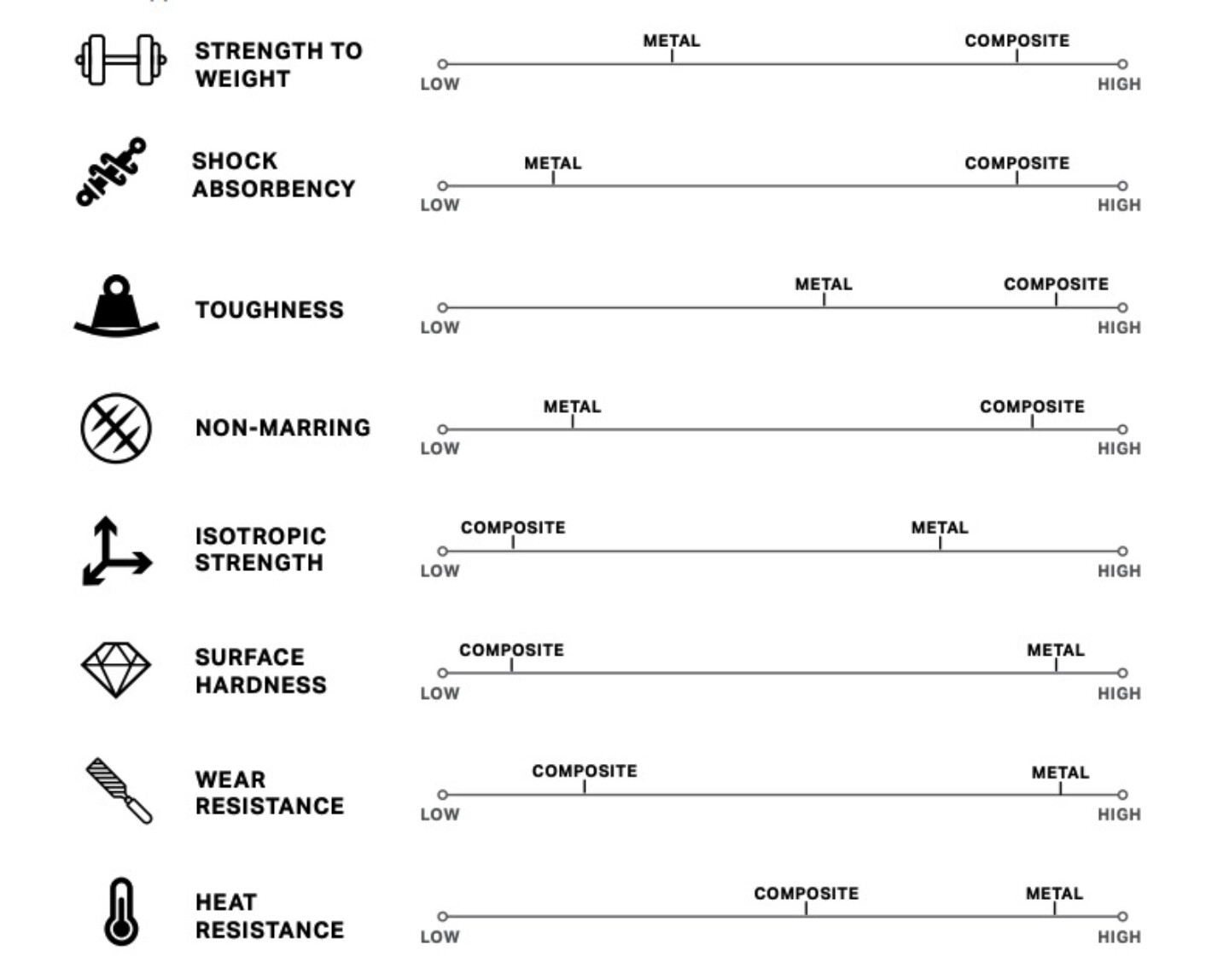

How 3D-printed metals and composites differ in their general material properties

Polymer 3D printing and metal 3D printing are two distinct manufacturing processes. Each can solve a wide range of manufacturing problems. The common denominator is that they both offer versatile opportunities to complement supply chains at every point: from functional prototypes, tooling and fixtures, and spare parts to low-volume end-use and production.

While both metals and continuous fiber-reinforced polymer composites work well in applications requiring high strength, application-specific considerations such as surface hardness and strength-to-weight ratio may result in the preference for either 3D-printed composites, metals, or hybrid composite-metal parts.

Typically, parts are printed from metal rather than composite materials because they must meet at least one of the following requirements: high strength, wear resistance, heat resistance, corrosion resistance, electrical conductivity, or thermal conductivity.

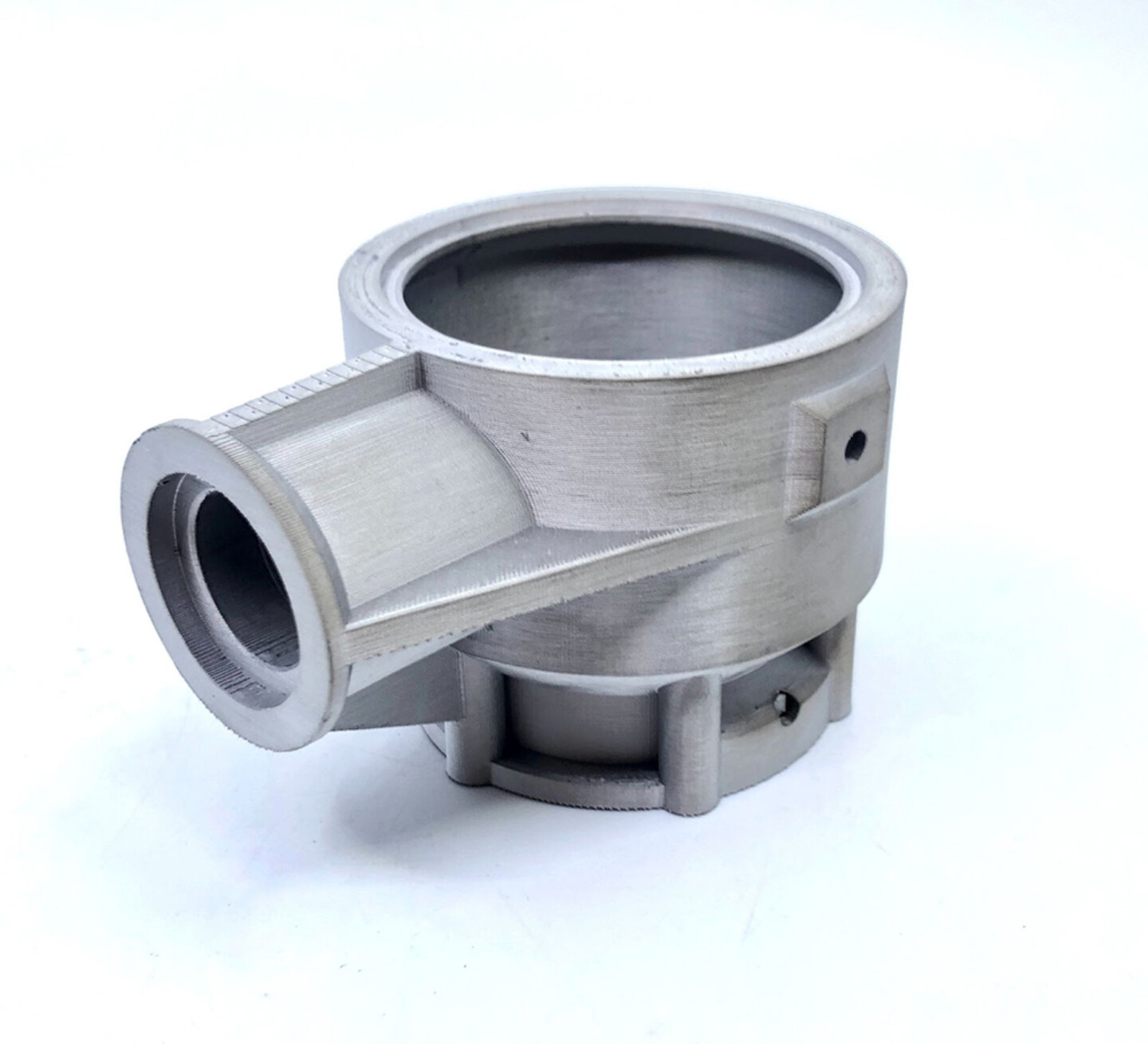

Manufacturers often print composite materials to quickly create prototypes of parts that will later be made of metal. Some prototypes require specific material properties that prevent composite prototypes from being functional. After producing working prototypes with metal FFF, users often ask themselves: Why not use this process in production? A comparison of the tooling costs for producing parts using processes like casting makes metal precasting a very attractive solution for scaling production to achievable quantities.

Traditionally cast coupling, printed on the Metal X System

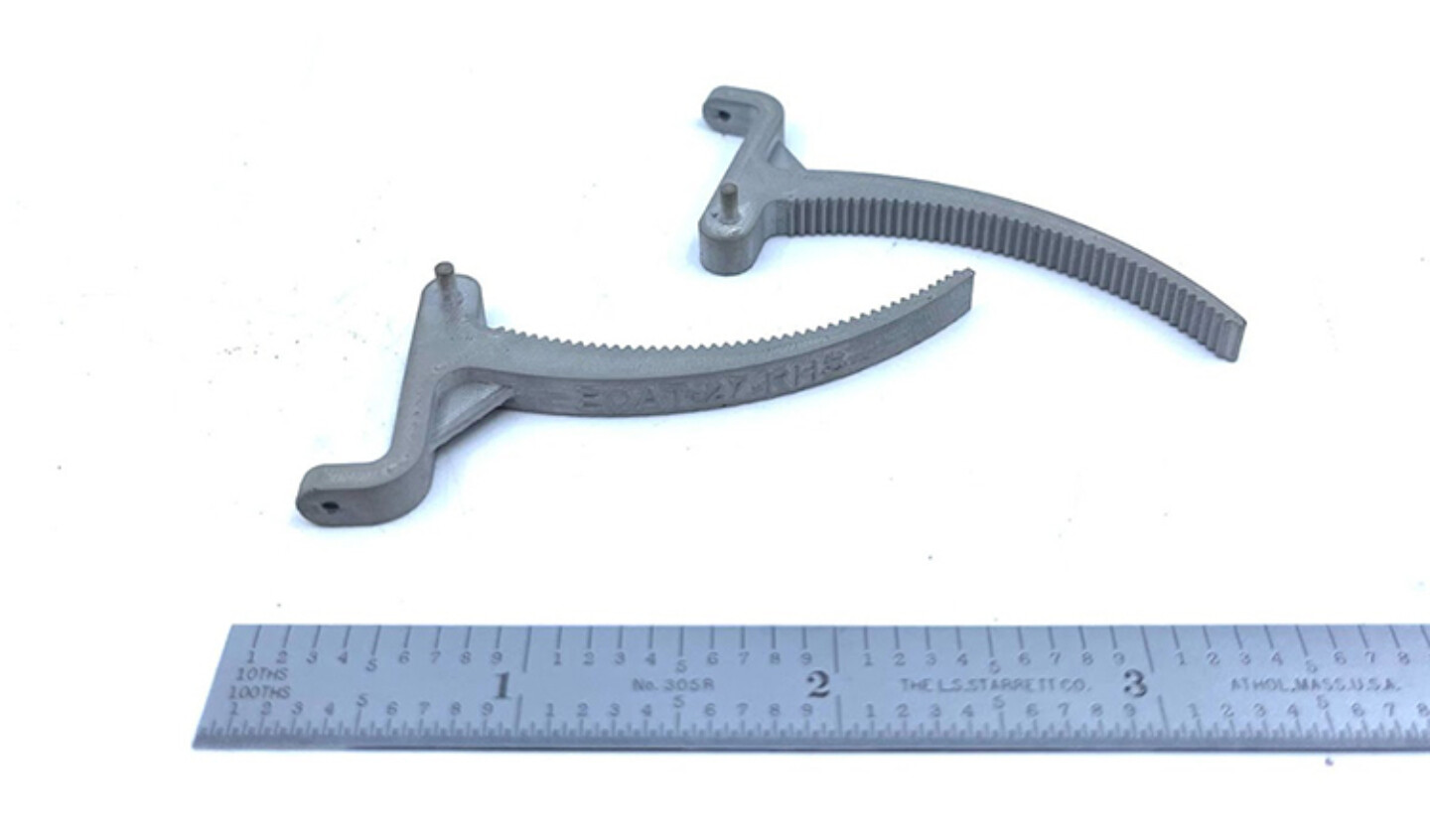

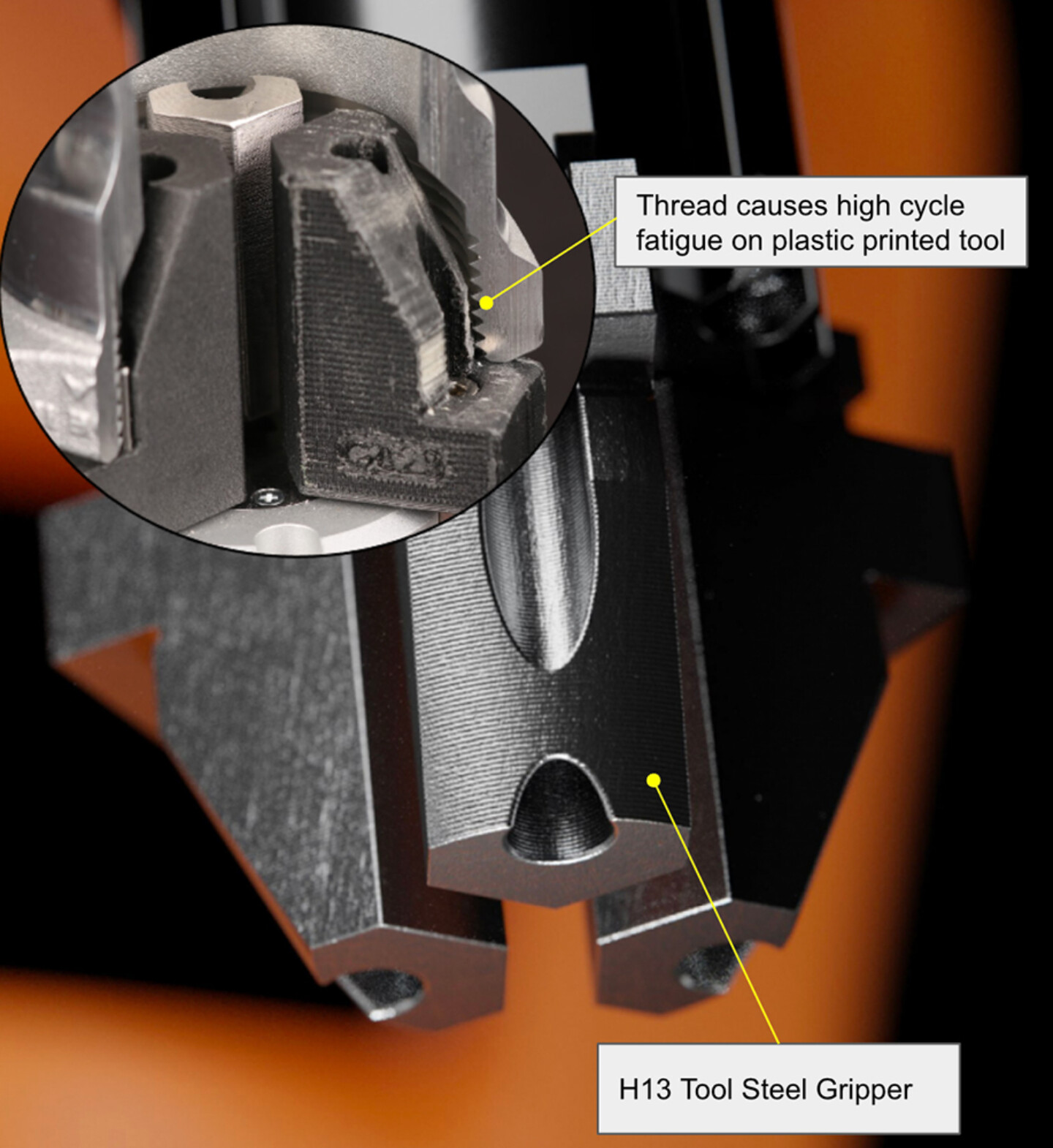

Tools are often printed from composite materials, but metal tools are more durable in terms of wear resistance and operation under extreme heat conditions. Parts requiring high strength with thin walls or complex geometries—such as end-of-arm tooling (EOAT)—may also be too small for continuous fiber reinforcement (CFR), the process used to reinforce 3D-printed composites.

Thin-walled tools

Higher surface hardness and strength increases the longevity of 3D-printed tools. Avoiding frequent replacement due to high cycle fatigue is a valuable advantage for applications such as bending and punching tools, grippers, fixtures, and custom hand tools.

Printed composite parts survive 10,000 cycles. Printed metal survives more than a million cycles.

The ability to print exotic materials such as pure copper also opens up applications that require electrical properties, such as welding shafts, busbars, and induction coils.

Cable lug 3D printed with pure copper

Although a metal part is heavier than a corresponding composite part, FFF-printed metal parts are still lighter than conventionally manufactured metals thanks to the closed infill structure automatically generated in Markforged's Eiger slicing software. This closed infill structure can make a metal part up to 50% lighter.

3D-printed metal bracket with closed infill.

Gooseneck V-block: traditionally manufactured (left) vs. 3D printed on the Metal X System (right)

On the way to metal: Starting with 3D-printed polymers

A major advantage of adding metal to the 3D printing toolbox is the ability to create hybrid parts. By using different combinations of metal, plastic, and reinforcing fibers, different material properties can be utilized to complement performance in complex applications.

Hybrid parts allow you to print larger parts and assemblies, lightweight metal parts with composite components, improve the material properties of composite parts, produce parts with better load-bearing capacity and force optimization, and increase part modularity. Parts and features of metal parts that don't require the material properties of metal can be printed faster with composite materials and combined through assembly.

If you have access to multiple 3D printers, these larger parts can also be produced faster by printing them simultaneously, allowing you to produce more parts that are critical to the supply chain.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar