At Walter Reckmeyer Werkzeug- und Maschinenbau, 3D printers are replacing entire CNC machining centers.

The company, based in the tranquil town of Augustdorf in the Lippe district, manufactures tooling for injection-molded parts for the automotive industry. Industrial 3D printing offers the company new flexibility and secures its competitiveness against competitors from the Far East.

High product variety in small batches

As a tooling manufacturer for injection-molded parts for the automotive industry, Walter Reckmeyer Werkzeug und Maschinenbau previously relied on CNC milling of aluminum components. A high product variety, small batch sizes, and low-cost competition from the Far East repeatedly presented the company with challenges. Particularly small quantities, with batch sizes of 1-2 for cable overmolding, were very expensive. Initial attempts with 3D printing and hobbyist suppliers failed due to the quality, accuracy, and mechanical properties of the components.

Request a DEMO component now!

See for yourself how strong the components are.

“For every 3D printer, I save on a CNC machining center. We are very satisfied with the reliability, process stability, and part quality.”

– Jan Reckmeyer, Managing Director, Walter Reckmeyer Tool and Machine Manufacturing

At a glance

Mechanically Robust Components from a 3D Printer

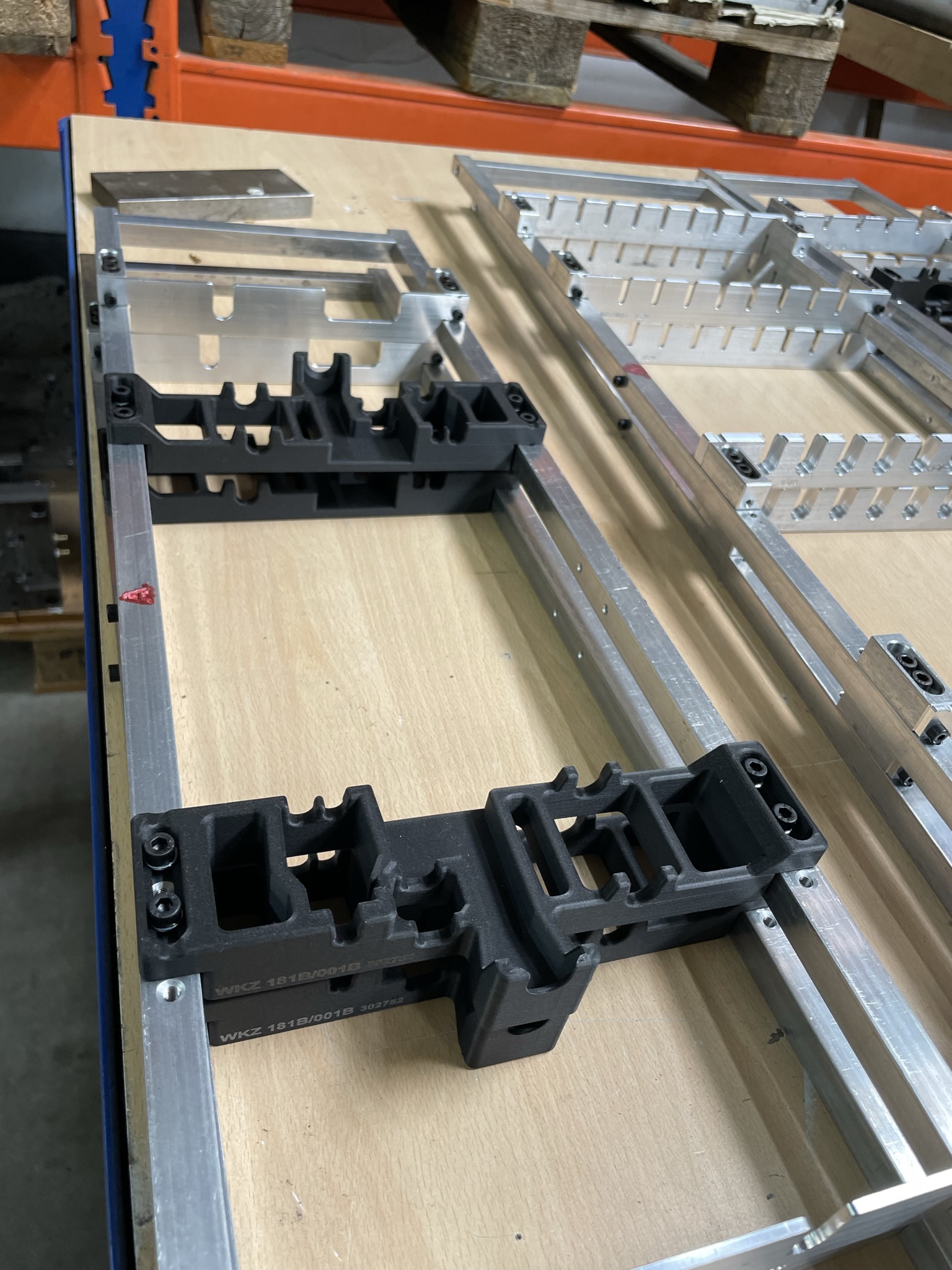

Jan Reckmeyer, second-generation managing director of the company, was introduced to Markforged 3D printers at an in-house trade fair and was impressed by their strength. He immediately recognized the added value for his company. Finally, he could envision an alternative to expensive aluminum parts: producing plastic components with the strength of aluminum using a simple system. Components that are also lighter and significantly cheaper to manufacture. Two industrial Markforged 3D printers were purchased: a Markforged Onyx One and a Mark Two for high-strength components. The Mark Two 3D printer also has the option of reinforcing components with continuous fibers made of carbon, Kevlar, or fiberglass. After a very short time, the 3D printers were being operated flawlessly and used as a genuine manufacturing technology.

Greater flexibility combined with improved cost-effectiveness

The results speak for themselves: Costs and production time have been reduced tenfold! Customer acceptance is fully present. A shift in thinking has taken place. The new requirements are now already geared towards additive manufacturing. For example, the zero-defect principle "Poka-Yoke" is expected by customers and is therefore directly integrated. "For every 3D printer, we save the cost of a CNC machining center, including the operator. Some of the new parts can no longer be manufactured conventionally from aluminum. The geometries are simply too complex. The effort would be many times greater," explains Jan Reckmeyer. Additive manufacturing will continue to reliably supply mechanically robust components for the automotive industry in the future – as a complement to conventional manufacturing.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.