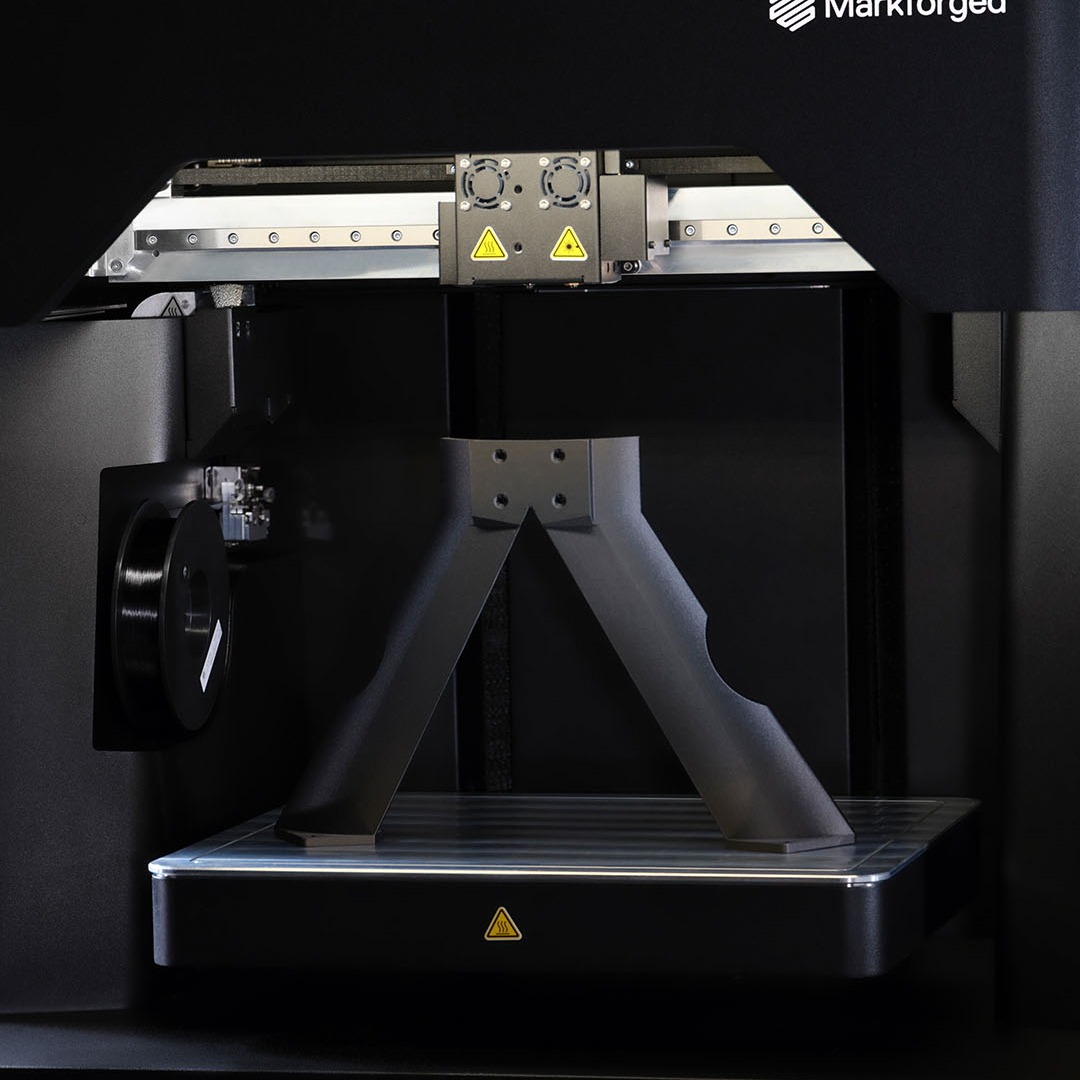

The Markforged FX10 – 5th Generation Industrial 3D Printer

The Markforged FX10 is the most versatile tool for your manufacturing needs and represents the next level in Markforged's industrial composite 3D printing technology, the result of years of research and technological advancements. Building on the success of the Markforged X7, its primary goal is to produce robust and precise parts every time.

With its new modular architecture designed for upgradeability and printhead-mounted optical sensors for dimensional accuracy verification and health and performance monitoring, the Markforged FX10 leverages advanced technology. Automatic calibration and material changes contribute to a user-friendly experience that's simple and low-touch, minimizing the need for surgical intervention.

With the new FX10 Metal Kit completely new possibilities open up – including 316L stainless steel.

The Digital Forge:

Powered by software

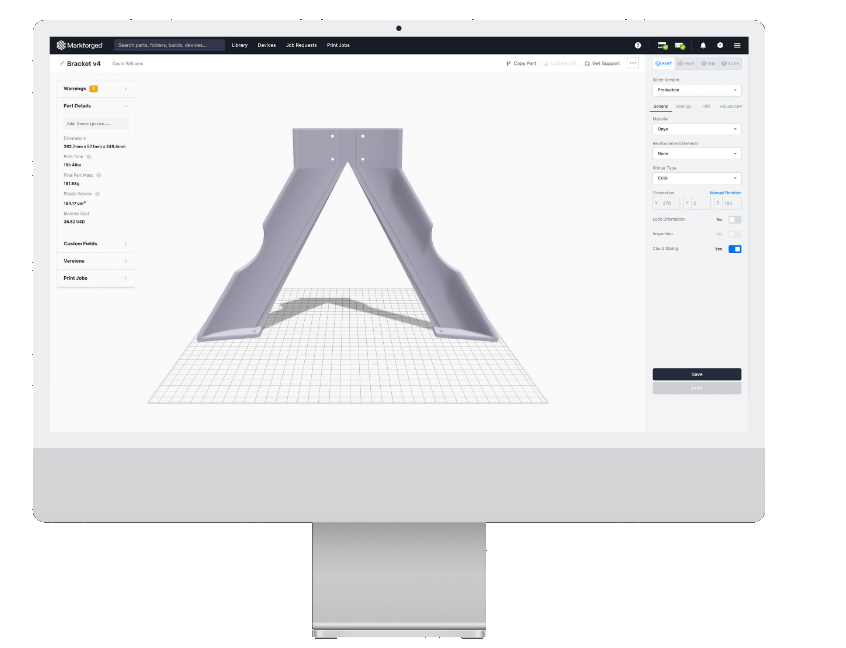

Markforged provides a simple, intelligent, and scalable additive manufacturing platform that integrates seamlessly into your manufacturing operations. Our Eiger™ software is designed with scalability in mind, providing a unified user experience, digital parts repository, and fleet management across the entire Markforged portfolio, including the new Markforged FX10.

Practical report:

How fixture construction works today

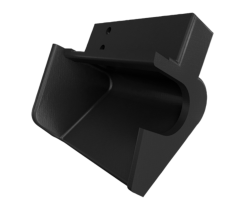

WESCAD has found creative and innovative ways to integrate industrial 3D printing into fixtures using the Markforged FX10. Ideal for equipment manufacturing, special-purpose machinery, and fixture construction.

These are not simple parts from a 3D printer.

The components are made of Markforged ONYX material and additionally reinforced with patented continuous carbon fiber. This achieves the strength of aluminum. This strength and the reliability of the system help reduce costs and optimize processes.

Image processing module and laser micrometer*

The Markforged FX10 features two optical sensors mounted on the printhead. The laser micrometer is used for inspection to check dimensions during print validation and machine calibration. The new vision module creates detailed images of calibration parts to determine and optimize printer performance.

*The image processing module will not be shipped with the first FX10 devices, but will be sent as a free upgrade package shortly after market launch.

Why continuous fibers?

Carbon fiber is only optimally designed to withstand tensile and compressive forces if the force acting on the component is applied in the direction of the fiber grain. If the carbon fiber is interrupted during the construction process, it can no longer absorb the optimal tensile and compressive forces. This is why the continuous fiber is so crucial for the stability of a component printed with carbon fiber, Kevlar®, or glass fiber. Continuous fiber-reinforced 3D printing thus ensures strength at a completely new level.

The technology: CFF

Continuous Filament Fabrication

Fiber-reinforced components are made of two materials and are incredibly strong and versatile. Our unique manufacturing process allows you to print components that are much stiffer and stronger than typical 3D printed parts.

DESIGN

Create an STL file from your CAD model and load it into the EIGER software. Select the appropriate composite material, such as carbon, fiberglass, or Kevlar. The cloud-based software will do the rest, making it easy to print the right part.

STRENGTHEN

The dual material system produces the fiber-reinforced component layer by layer. The first nozzle forms the plastic matrix, and the second nozzle continuously deposits the composite fiber.

COMPONENT

Markforged CFF components are as strong as aircraft aluminum and over 40% lighter than machined metal tools, fixtures, and prototypes.

Metal 3D printing with the Markforged FX10

The latest development from Markforged: The world's first industrial 3D printer for composites and metals

The Markforged FX10 has received a major upgrade.

With the new FX10 Metal Kit completely new possibilities open up – including 316L stainless steelThe FX10 prints composite materials by default. Metal printing is possible with an optional expansion kit compatible with all FX10 printers.

After the components have been printed, they still need to be debound and sintered.

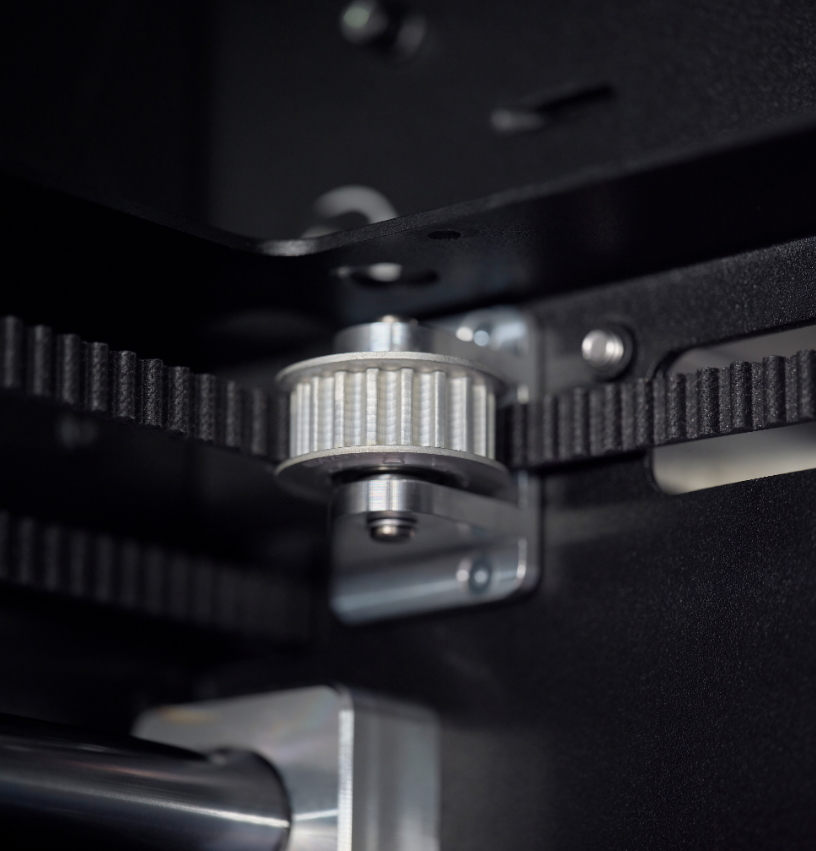

Heated print chamber and vacuum bed

The Markforged FX10 features a large build chamber that heats up to 60°C, which is advantageous for printing high-quality parts at high speeds. The aluminum vacuum bed is also heated and features precision grooves that are scanned by the laser for calibration.

Modern material warehouse with automatic change

Internal material drawers store four spools in individually sealed compartments and support automatic material changes and rapid spool loading, minimizing the need for manual user intervention.

The Markforged FX10 increases the profitability and productivity of your manufacturing

| Technical features | Markforged FX10 |

|---|---|

| Construction volume | 375 x 300 x 300 mm |

| Z-resolution range | 125 – 250 μm |

| Installation space | Heats up to 60 °C |

| Materials | Engineering thermoplastics: Onyx™ Continuous fibers: carbon fiber |

| Power supply | 230 V |

| Weight | 109 kg |

| External dimensions | 760 x 640 x 1200mm |

Would you like a demo, have questions or need a quote for the Markforged FX10 3D printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers