The Markforged FX20

The FX20 is the largest, fastest, and most sophisticated 3D printer Markforged has ever developed. Designed from the ground up for unparalleled performance and reliability, the FX20 large-format 3D printer takes our patented composite technology to a larger scale, creating new opportunities for new applications and industries. Capable of printing high-temperature thermoplastics with continuous carbon fiber, it delivers high-strength, aerospace-grade parts at the touch of a button.

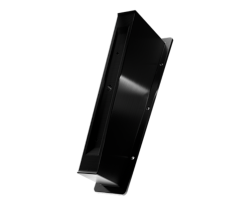

Larger and heated build space for your applications

An even larger, heated build chamber ensures components of the highest quality. It includes a heated build chamber that can maintain a temperature of up to 200 °C.

Prints up to 8 times faster than the standard print settings of Markforged's existing composite printers.

– Large material spools with 3200 cm²

– 3 nozzle print head

– Precision-ground vacuum bed

– Reusable printing sheets

– Touchscreen interface

Practical report:

With the Markforged FX20, KST Moschkau GmbH minimizes production costs to one sixth

When demand for a new product exceeded expectations, security systems manufacturer KST Moschkau chose the Markforged FX20 to bypass complex supply chains with scalable production.

The result? The Markforged FX20 reduced lead times from 3-4 weeks to 2 days. Production costs are one-sixth of those using multiple aluminum components from external CNC shops.

Even more stable components with ULTEMTM 9085 filament

Built for everything from high-performance tools and fixtures to flight-ready production parts, the FX20 is the first 3D printer in the Markforged family to be able to reinforce ULTEM™ 9085 filament with continuous carbon fiber.

The material is particularly characterized by its high heat and chemical resistance and also has extremely high tensile and flexural strength.

In addition, materials such as Onyx, Onyx FR, Vega*, Onyx ESD*, Ultem 9085, the continuous carbon fiber, the continuous carbon fiber FR, continuous glass fiber* and the continuous Kevlar fiber*.

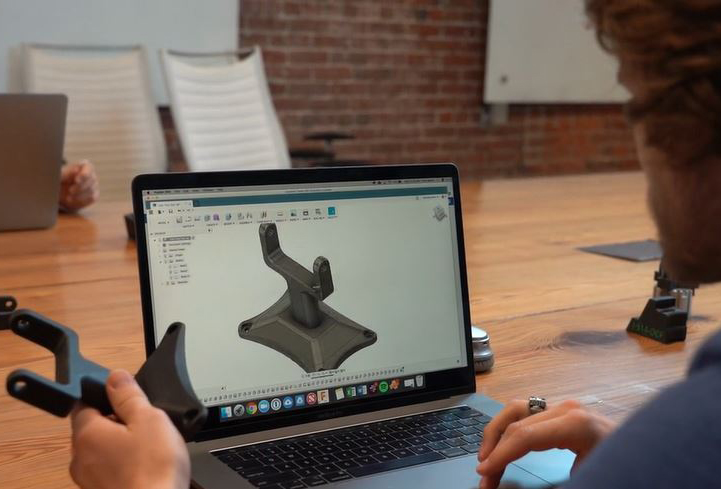

In the picture on the left, our colleague Jan Geese, Head of Application Engineering, is pictured with a feed shoe from PLAN4 Engineering GmbH. The component, measuring 501 x 396 x 344 mm and 3160 cm³ of Onyx, was printed in approximately 66 hours on the Markforged FX20.

The “ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Massive components, available even faster with the Markforged FX20

The FX20 combines size and productivity to produce significantly larger parts incredibly fast. The build volume is nearly 5x larger than other Markforged printers. And the completely redesigned motion and extrusion systems enable high-speed 3D printing without compromising quality.

The Markforged FX20 is also a precise, sensor-controlled machine that offers the highest reliability and is easy to operate. Fully integrated storage and handling keep materials dry during printing, while sensors fully monitor the extrusion system. Linear encoders on the gantry and print bed provide precise, real-time feedback on the machine position, ensuring high-precision parts.

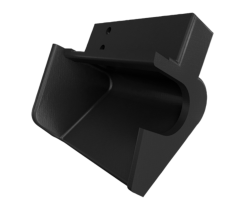

The print head

Designed for fast and reliable printing with high-performance materials

2 modules for plastic

– Matrix material

– Support material

1 module for long fibers

Optimized for retracting

Movable nozzle modules

The drive system

Designed for high speeds

Rigid and thermally robust frame construction

Powerful servo motors

Micrometer-precise linear encoders on each axis

closed process control

Industrial materials for the Markforged FX20

*These materials are not currently compatible with the Markforged FX20. These plastic and fiber materials will be added over time, but not for every combination.

The technology: CFF

Continuous Filament Fabrication

Fiber-reinforced components are made of two materials and are incredibly strong and versatile. Our unique manufacturing process allows you to print components that are much stiffer and stronger than typical 3D printed parts.

DESIGN

Create an STL file from your CAD model and load it into the EIGER software. Select the appropriate composite material, such as carbon, fiberglass, or Kevlar. The cloud-based software will do the rest, making it easy to print the right part.

STRENGTHEN

The dual material system produces the fiber-reinforced component layer by layer. The first nozzle forms the plastic matrix, and the second nozzle continuously deposits the composite fiber.

COMPONENT

Markforged CFF components are as strong as aircraft aluminum and over 40% lighter than machined metal tools, fixtures, and prototypes.

Eiger Software

3D printing with composite fibers is as much about the software as it is the unique technology of the printers. The Markforged EIGER software is both powerful and easy to use in your browser. It imports your drawing and optimizes it for 3D printing.

Design your part, upload it to the browser-based Eiger software, choose from a wide range of composite or base materials, add a continuous fiber if needed, and click "Print." It's that simple.

Would you like a demo, have questions or need a quote for the Markforged FX20 3D printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers