Continuous fiber optic cable

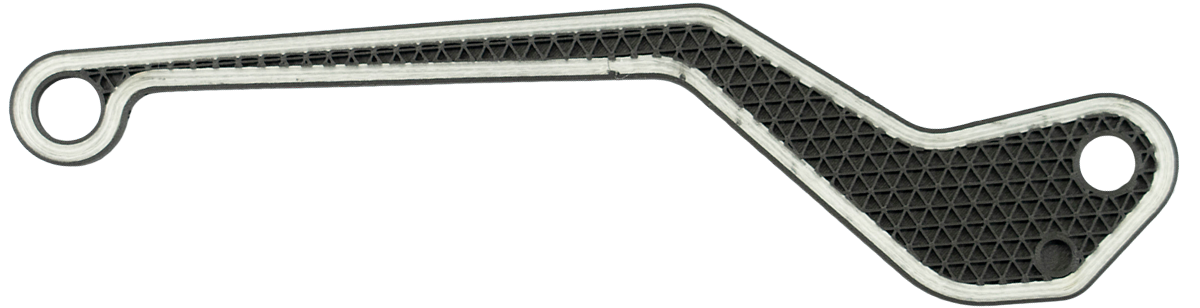

3D printed fixtures for a laser welding machine

Primetall GmbH faced the challenge of requiring different fixtures for a laser welding system due to the investment in a new facility. Previously, these fixtures were conventionally manufactured from aluminum.

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

FAQ

What is continuous fiber optic cable?

Glass fibers are extremely thin strands of glass bundled together to form a single fiber. Glass fibers are traditionally used in composite materials for boat, automobile, and aircraft construction.

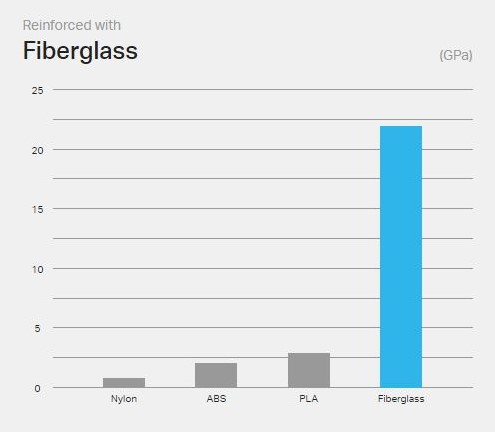

How strong is continuous fiber optic cable?

Fiberglass has a flexural strength of 200 MPa (29.0 ksi) and a tensile strength of 590 MPa (85.5 ksi). For more information on the properties of 3D printed continuous fiberglass, see the datasheet.

How much does continuous fiber optic cable cost?

A 50 cc spool costs €83.00 including VAT and a 150 cc spool costs €230.00 including VAT.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.