3D printing of metals easier than ever before – an industrial revolution

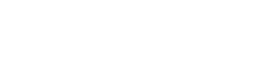

The Metal X significantly accelerates your innovation and delivers metal components unmanned. Create everything from industrial spare parts to injection molds to functional prototypes.

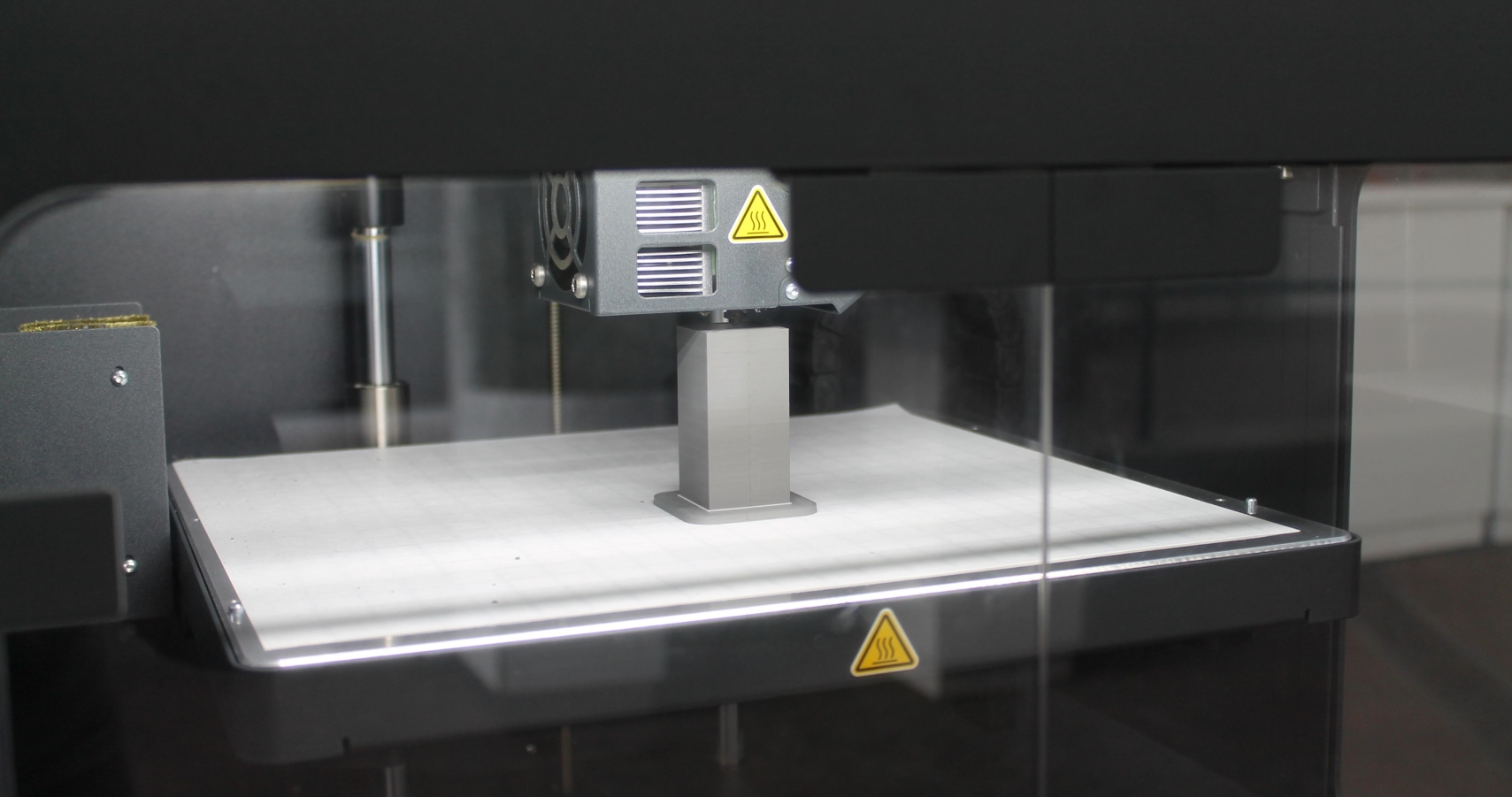

The Markforged Metal X system is a simple way to manufacture complex metal parts from a variety of modern metals.

From design to fully functional

Metal parts in less than 28 hours – with the Markforged Metal X.

Simple, yet powerful!

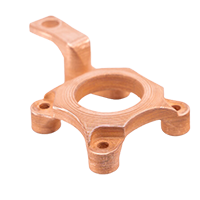

The Metal X is one of the most intuitive metal 3D printers on the market. Print a wide range of materials, from stainless steel to copper, with minimal training in a closed-loop workflow. Scaling capacity is easy; simply add printers.

Safe and cost-effective.

The Metal X is designed to be safe to operate and accessible to all users. Its cost is several times lower than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

High-quality parts, received quickly

The Metal X is purpose-built for consistent part quality and a seamless user experience. Markforged combines superior software, materials research, and an advanced drive system to deliver industrial-quality parts quickly and reliably.

Practical report:

Stanley Infrastructure saves over 90% of time and money with metal 3D printing!

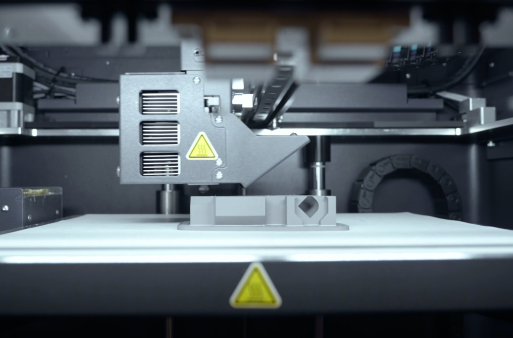

Cost savings, more efficient work, and greater flexibility. Stanley's actuator housing was optimized using metal 3D printing. Stanley engineers redesigned the part to enable printing on the Markforged Metal X. Instead of a four-part assembly, the redesigned part is printed in one piece without any support material.

Find out why Stanley Black & Decker is so confident in the Metal X's metal 3D printing technology.

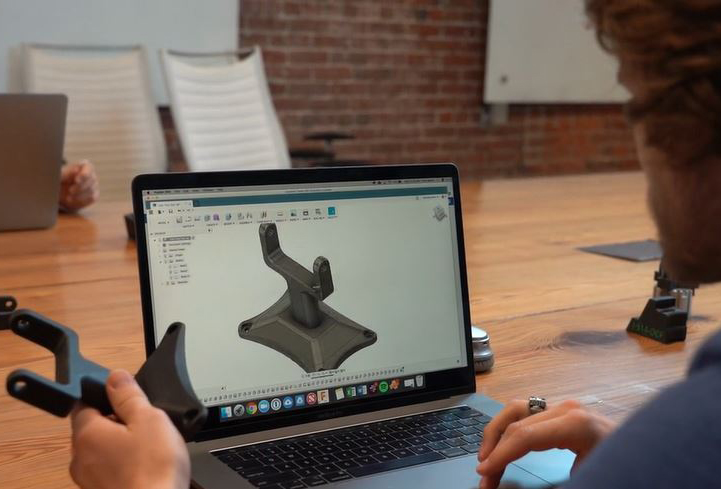

The ADAM technology

Atomic Diffusion Additive Manufacturing – The Process of Markforged Metal X

The Metal X uses innovative technology to print metal. The printing material consists of a very high concentration of metal powder bound in plastic and wax. It is then printed using the proven FFF/filament process – completely without metal dust. The wax content is removed from the component through debinding. The subsequent sintering process results in atomic diffusion. The end result is a homogeneous metal component.

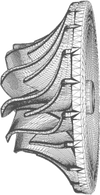

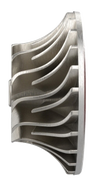

ADAM also allows you to create unique geometries such as closed honeycomb structures. Components resembling a complex bone structure can be realized with the Metal X: a closed cell inside, encased in a stable outer shell. These geometries could not be manufactured using a traditional subtractive process or even with direct metal laser sintering (DMLS).

Large build volume, high-quality resolution

The large build volume of the Metal X enables the automotive, aerospace, and many other industries to produce main components, individual parts, or spare parts quickly and cost-effectively. The components can be printed with a layer height of 50 μm, ensuring even the smallest details with the highest precision.

Request a DEMO component now!

See for yourself the strength of metal printing.

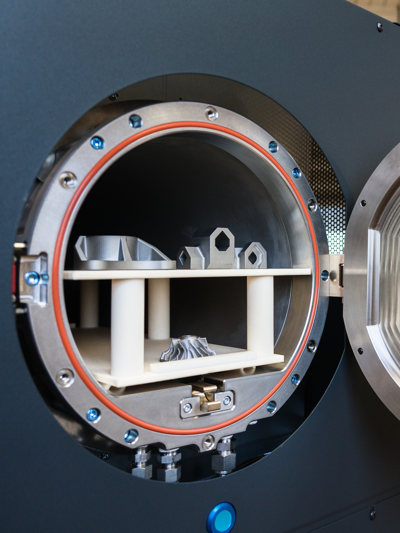

Support structure with ceramic layer

The support structure is printed from the same material as the component. A ceramic release layer is applied via a second nozzle in the print head. This separates the support structure from the component. This support structure can be removed easily after sintering – almost without the need for tools.

Design your part, upload it to our browser-based software, choose from a wide range of metals, and press print. It's that simple.

Print components with familiar precision and tolerance.

Define tolerance specifications in Eiger, the included cloud-based 3D printing software.

Technical features of the Markforged Metal X

The most important information about the Markforged Metal X at a glance.

| Construction volume | Stand area | |

|---|---|---|

| STAINLESS STEEL | COPPER | INCONEL |

|---|---|---|

| Security | productivity | Software Platform |

|---|---|---|

| All-round carefree package | |

|---|---|

| Extended Service and Warranty [Optional] |

The metal 3D printing process in detail

Metal 3D printing in 3 steps

How does metal 3D printing work with Markforged?

How does the process differ from 3D printing with plastic? Which metals can already be manufactured additively? How does metal 3D printing work without toxic metal dust? What downstream processes are there?

Learn more about metal 3D printing!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote?

You can leave us a message here:

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.