Machining metals with 3D printed plastic tools?

Sounds crazy?

Together with Gühring KG, we have embarked on this groundbreaking project.

We show whether it worked and what else we tested in this detailed video report!

Request a DEMO component now!

See for yourself how strong the components are.

Gühring KG processes metals with plastic end machining

tools!

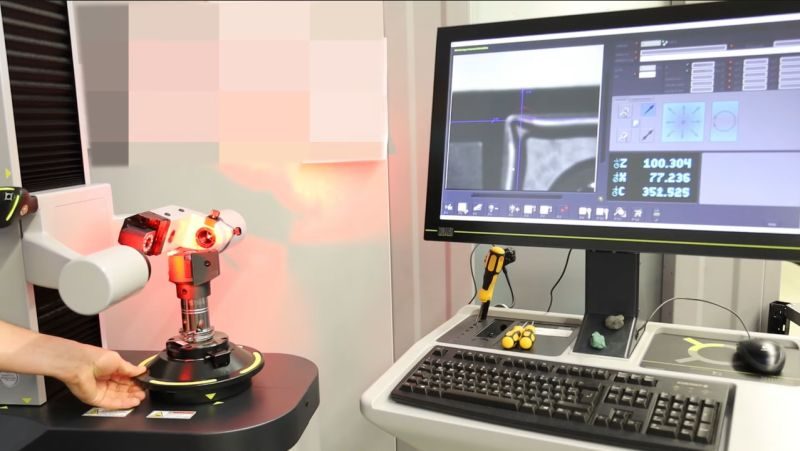

Together with Mark3D and Markforged, Gühring KG conducted revolutionary experiments at its Markt Erlbach plant: end machining of metals with 3D printed metal and plastic tools!

CNC machining requires custom tools for various metal parts. Even the production of such a special tool requires lead times of at least six weeks. Furthermore, the finished tools must be free of imbalance or other features that could disrupt the machining process and compromise occupational safety.

Gühring KG wanted to complement its GE100 finisher series with additively manufactured tools. The 3D-printed metal carrier is designed to machine the metal piece to be machined with multiple contours in a single pass.

From the start of printing to the finished component, production was reduced to just three days with the Markforged Metal X system! The shank and insert seat can be finished as usual through post-processing to ensure the required precision. In addition to the significantly shorter production time, there's another advantage: the honeycomb structure (infill) inside the tool makes it significantly lighter than the machined tool.

"I've spent several years in the CNC and CAD/CAM world. That's why this project was extremely interesting to me. We invested a lot of time in the development and design of the tools and were very excited about the results. When we went to the machine, tested the tools, and saw the first chips, we were absolutely thrilled. The tools ran very smoothly. I'm sure there's still a lot of potential and we're just at the beginning with these tools."

– Dario Popovic, Strategic Application Engineer Central Europe, Markforged

How were the tests conducted?

Testing was carried out with aluminum and stainless steel, and the 3D printed tool easily withstood both challenges.

The tests with the 3D-printed metal tools went extremely well – if you didn't know better, you wouldn't even notice that the parts were additively manufactured! This prompted Gühring to think a step further: Would metalworking also work with 3D-printed plastic tools? If so, then lead times and costs could be reduced even further.

For this test, Gühring KG, with the professional help of Markforged and Mark3D, printed an end machining tool with the Markforged X7 from the base material Onyx (PA6 with short carbon fiber content) and additionally reinforced the component with the continuous carbon fiber for maximum stability.

This tool was printed within a few hours and immediately ready for use. Gühring first tested the plastic end-machining tool on an aluminum tube. To everyone's delight, the plastic tool easily met the requirements.

The tool was then tested for the same purpose on a stainless steel pipe. Stainless steel requires significantly more force to machine than aluminum, but the plastic tool still held up.

"Gühring KG stands for technological leadership. Additive manufacturing has also arrived in our industry, and we are naturally developing in this direction. This technology can mean enormous time and cost savings for us. Where we reach the limits of conventional manufacturing, additive manufacturing offers us completely different possibilities for designing new tools. It's certainly not for series production (yet), but we'll see what the future holds."

– Anja Krehn, Plant Manager Markt Erlbach, Gühring KG

Conclusion

All in all, these experiments have shown that additive manufacturing can already produce high-strength components and is a genuine manufacturing technology that perfectly complements conventional manufacturing.

Mark3D Managing Director Joachim Kasemann adds:

"According to the motto: manufacture additively what you need to machine but don't want to machine! This is manufacturing redefined. Availability. Independence. Innovation."

Learn more about the applications of Markforged 3D printers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.