3D printing in special machine construction

Design and 3D printing in special machine construction and project planning

Peil Maschinenbautechnik designs and prints (almost) everything with the Markforged Mark Two 3D printer: from brackets, functional components and force-loaded machine components to holders for circuit boards and molds for silicone parts.

His customers come from all areas of mechanical engineering, the medical industry and mold making, among others.

Peil Maschinenbautechnik also offers experienced 3D printing and design services.

Challenge

Respond quickly and individually to customer requests:

At Peil Maschinenbautechnik, the primary focus is on custom machine construction, which is why virtually no component is used twice. Before purchasing the Markforged Mark Two, management had parts turned or milled, and the supplier also implemented sheet metal designs for them at short notice. Now, this is no longer possible, and the larger companies in the area have longer waiting times, and single-part production is also quite unattractive and expensive. Therefore, a solution was needed that could replace these aluminum parts quickly and precisely, but with no lesser durability.

3D printing in special machine construction

At a trade fair, Managing Director Thomas Peil was introduced to Markforged 3D printers and was impressed by the strength provided by the continuous fibers and the resulting application possibilities. Now, even components can be printed that would have been impossible to manufacture any other way.

Solution

“I’ve certainly achieved the ROI just because of the significant time savings.”

Thomas Peil makes the immense time savings clear in the following example: "Friday at the customer's, Saturday the idea was in mind and designed, Sunday the Mark Two printed, Monday the finished component was installed at the customer's! So far, I've been able to rely completely on the technology of the Markforged 3D printers."

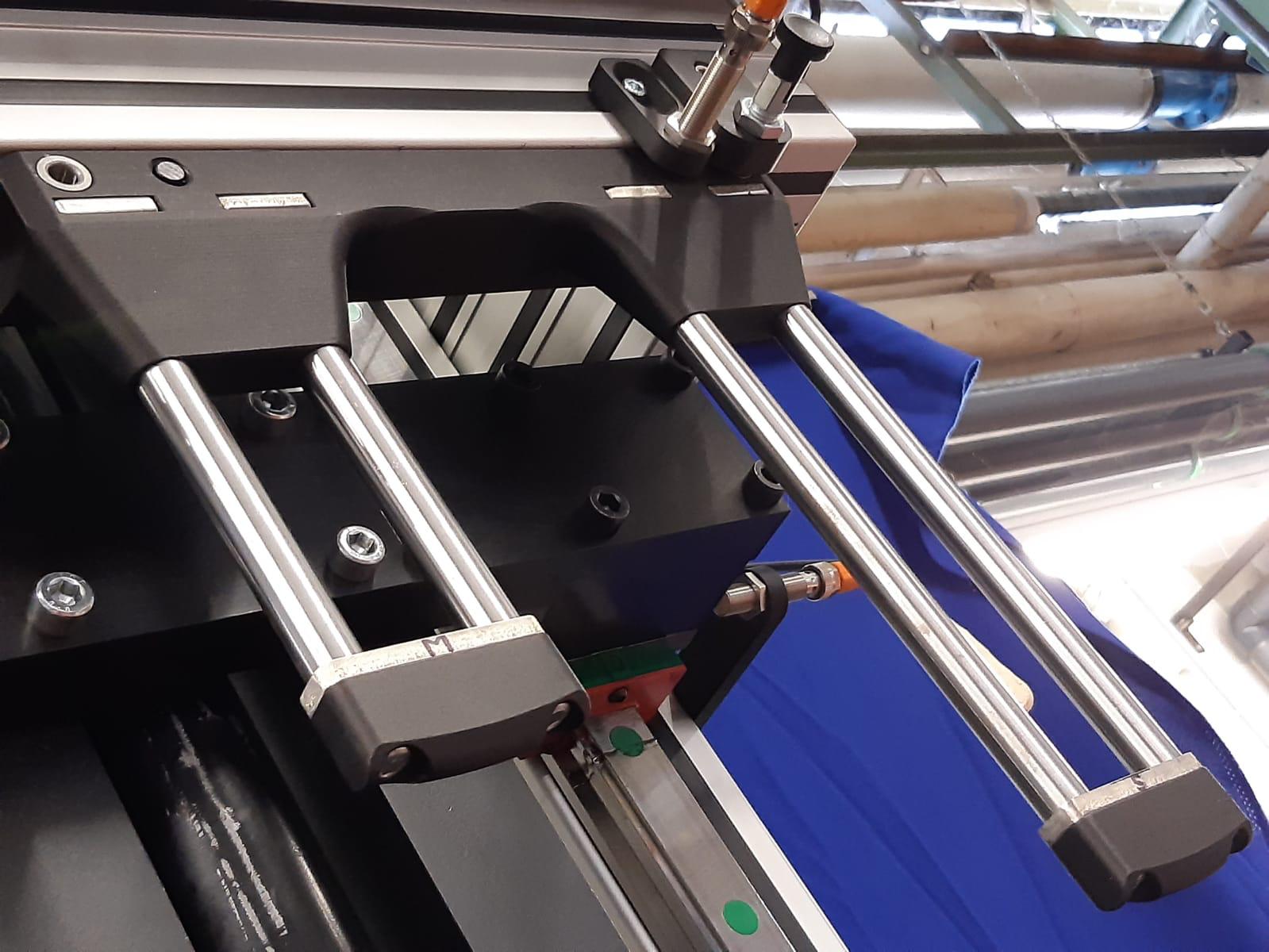

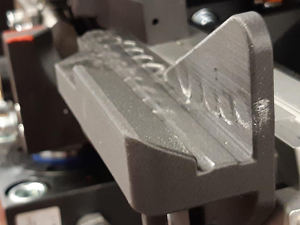

Now, truly multi-talented tools can be manufactured. For example, two metal ends are joined on a machine. These move precisely into position until they are flush against each other. Previously, the metal parts moved directly to the light barrier – but this was too inaccurate. Thanks to the intermediate part, the positioning is now 10x more precise! The surface of the movable Onyx part that touches the article is implemented with a simple insert plate. This reduces wear and is replaceable. The small slot for the inserted part could not have been manufactured using conventional methods!

Peil Maschinenbautechnik frequently works with parts that are subsequently inserted or plugged into the component: Magnets with nut holders are screwed into the side of the article holder. They can be moved in the groove on the inside and secured with the square thread printed from onyx (which also serves as a torque lock for the nut). To prevent excessive wear, the same magnets are used to hold a spring steel sheet in place on the front, which comes into direct contact with the articles.

Advantages at a glance:

Request a DEMO component now!

See for yourself how strong the components are.

Other projects

A Mark Two for every challenge

Thomas Peil is brimming with inventiveness! "Getting suitable proximity switch holders with locking pins or strain reliefs in custom sizes is a challenge – but it's easy to design and print them quickly." The same applies to the rollers and holders that protect the hydraulic hoses at the edge of the machine from wear and tear, so they don't rub against the edge during constant movement.

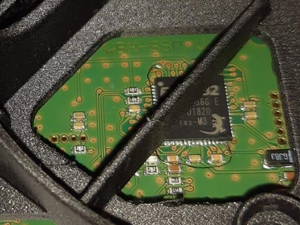

For a small electrical appliance, Peil Maschinenbautechnik not only designed a circuit board mount, but also the non-millable geometry of the component. The wave-shaped rings in the component are designed as an elastic pressure point for deactivating the sensor technology.

The feed of the items for the above-mentioned light barrier construction is handled by the console. Here, you can again see the circles of the magnets built into the component, which hold and move the item. This feeder had to be redesigned several times during development to achieve the best possible geometry – which would have been very expensive using conventional manufacturing processes.

3D printing offers a multitude of new possibilities in special machine construction.

Contact details

Peil Mechanical Engineering

Friedrich-Rech-Str. 183

56566 Neuwied

Phone 02631 9789490

Mobile 0160 1551900

Email tpeil@peil-mbt.de

Internet www.peil-mbt.de

“The big advantage of additive manufacturing is that you can produce any shape with the material on the spool.”

– Thomas Peil, Managing Director

Learn more about the applications of plastic 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.