The company

As a world-leading provider of sustainable and innovative architectural lighting with over 1000 employees in more than 55 countries, the long-established company ERCO is committed to timeless design and state-of-the-art technology, in particular the 100% use of LED technology.

The challenge

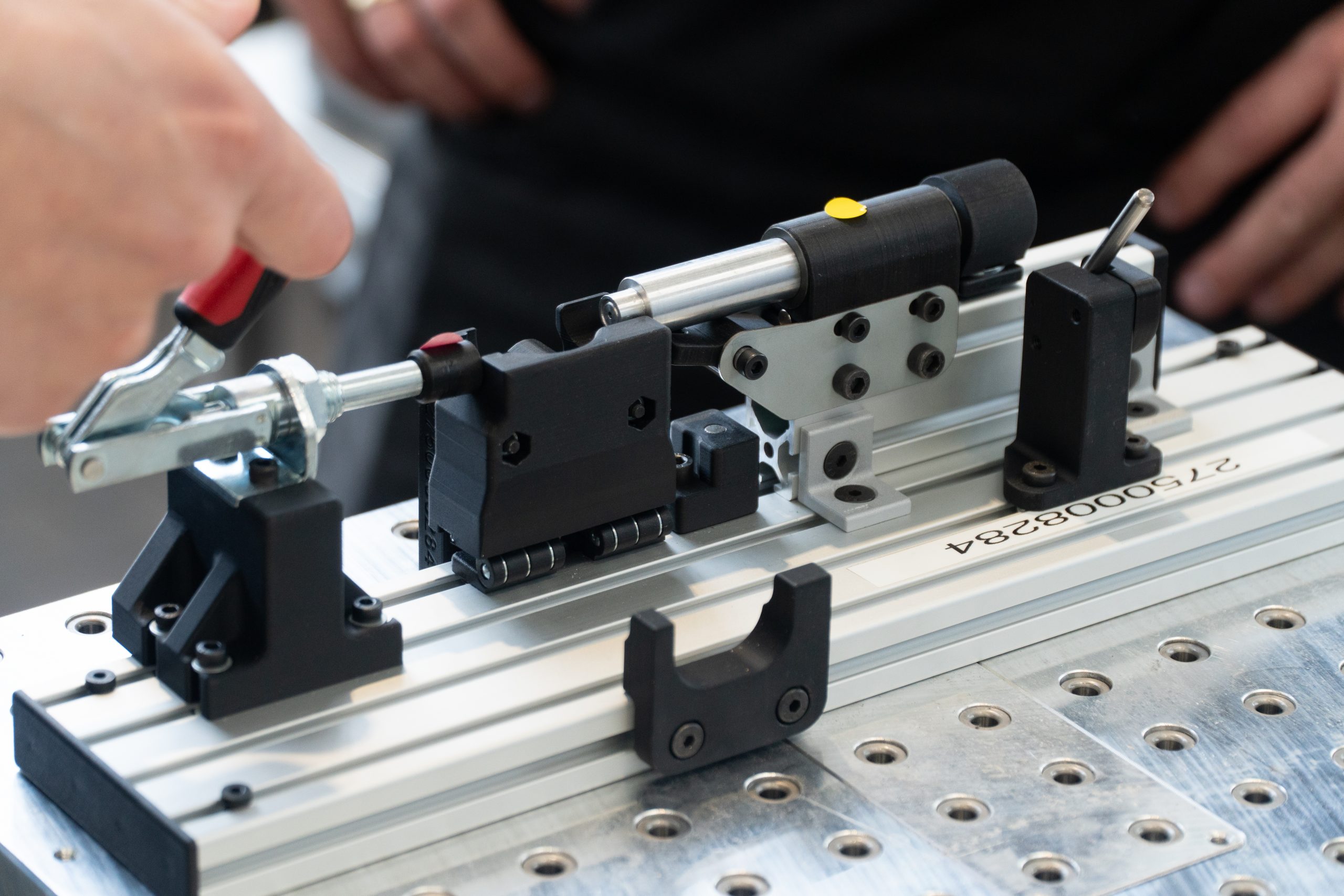

Customized Fixtures

In ERCO's tooling department, Stephan Jungkurth and his colleagues faced, among other things, the demanding task of producing custom-made fixtures for circuit board lights, ensuring that these fixtures would not accumulate static electricity. This is crucial because, until now,

the production of these components involved considerable effort in the mechanical processing of aluminum, PVC, or polyethylene semi-finished products. Furthermore, increasing delivery times and prices for ESD-safe boards led to a steadily growing inventory of semi-finished products.

At a glance

Solution

Additive Manufacturing with ESD-Safe Materials

In spring 2021, a specialist group within ERCO's technology management initiated the search for an industrial 3D printer capable of reliably and securely processing ESD-safe printing materials. This requirement was necessary because the assembly of circuit board lights and other products can only be achieved by eliminating any static charge. This is the only way to protect both the products and the operators from potential damage. After a thorough performance comparison, the choice fell on an industrial 3D printer from the Markforged X-Series.

Implementation of a New Manufacturing Process

The procurement of initial 3D-printed components began through a Mark3D service provider and evolved from a testing phase into a crucial element in the selection process. This phase not only facilitated knowledge exchange but also the targeted development of expertise in process-oriented design, the so-called Design for Additive Manufacturing (DfAM). The results demonstrated the potential quality, and expectations for the technology could thus be clearly defined. In May 2022, an investment was made in an industrial Markforged X-Series 3D printer. Commissioning by Mark3D GmbH was completed in a very short time, and the technology was operational within just two hours.

“The Mark3D system

is simple, reliable, and process-safe. Excellent user-friendliness completes the package.”

– Stephan Jungkurth, Head of Tool Mechanics, ERCO GmbH

Request a DEMO component now!

See for yourself how strong the components are.

Applications

Today, the focus is on the industrial production of fixture components. An increasing number of components, such as assembly fixtures, supports, inserts, clamps, locking devices, testing fixtures, and alignment devices, are being manufactured unmanned for assembly. Other equipment, such as custom grippers and handling systems for automating injection molding machines, as well as rapid visual samples and prototypes, are now also being printed regularly. A large number of components were converted to industrial 3D printing and thus also to digital warehousing in a very short time. "The process is simple and reliable," explains Mr. Onjanov from the fixture design department.

Vorrichtungs-Konstruktion.

Industrial 3D printing has significantly changed ERCO's internal process chain.

The team's learning curve is constantly rising, and as a result, the internal process chain has been more than halved, from procurement to post-processing. The design team benefits from unprecedented freedom, short-term availability, and independence from third parties. Since its commissioning in May 2022, the industrial Markforged 3D printer has already logged approximately 7,500 operating hours by July 2023, which equates to roughly 17.5 hours per day. In some months, it operates at 80% capacity, 24 hours a day, 7 days a week. Thanks to its trouble-free operation, the 3D printer has already paid for itself in just 1.5 years.

The future

Machine Maintenance

In the future, further applications within the company will be identified and evaluated to further utilize the current 3D printer.

The use of industrial 3D printing in machine maintenance is also being examined. Since particularly mechanically robust components are required here,

this would be a potential application area for components reinforced with Markforged continuous carbon fiber. Furthermore, other materials such as Smooth TPU95A will be tested.

Learn more about the applications with the X7!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.