Description

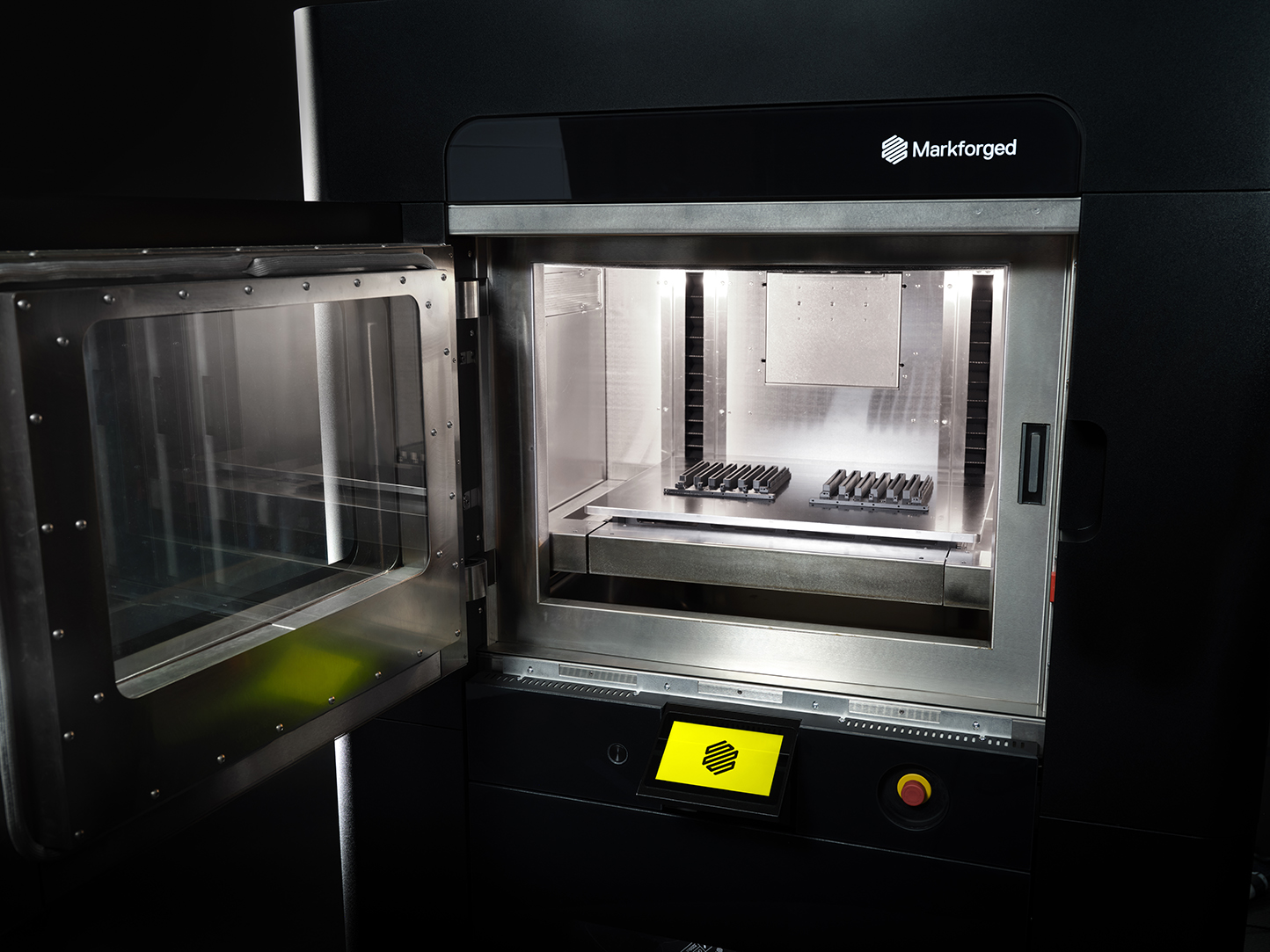

The Markforged FX20

The beast of additive manufacturing!

The FX20 is the largest, fastest, and most sophisticated 3D printer Markforged has ever developed. Designed from the ground up for unparalleled performance and reliability, the FX20 large-format 3D printer takes our patented composite technology to a larger scale, creating new opportunities for new applications and industries. Capable of printing high-temperature thermoplastics with continuous carbon fiber, it delivers high-strength, aerospace-grade parts at the touch of a button.

Learn more about the FX20 here.

Even more stable components with ULTEMTM 9085 filament

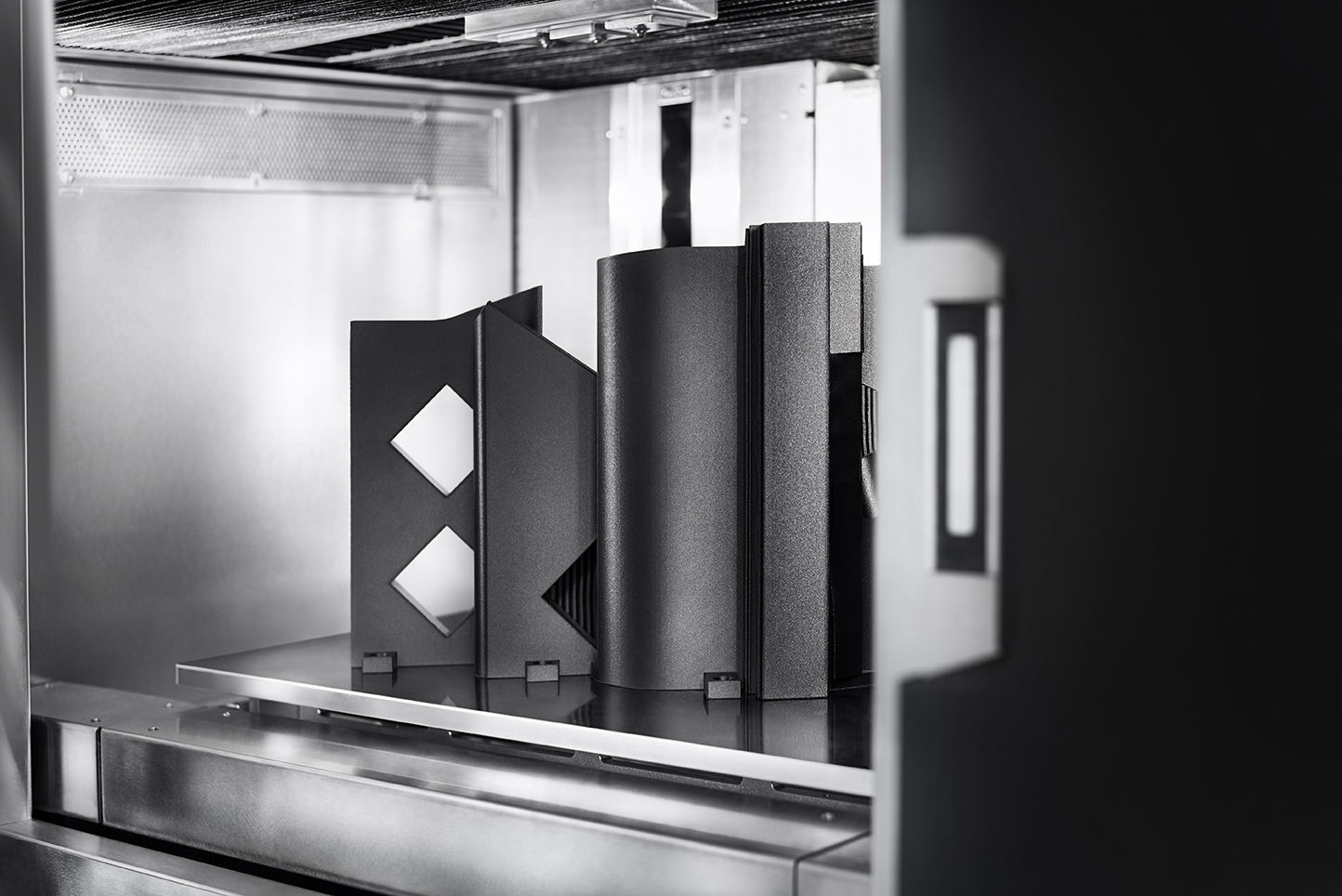

Built for everything from high-performance tools and fixtures to ready-to-fly production parts, the FX20 is the first 3D printer in the Markforged family to be able to print ULTEM™ 9085 Filament reinforced with continuous carbon fiber.

The material is particularly characterized by its high heat and chemical resistance and also has extremely high tensile and flexural strength.

In addition, of course, the conventional materials can be printed such as Onyx, Onyx FR, Onyx ESD, Nylon White and a support material for ULTEM TM 9085 the ULTEM TM Filament Support.

The “ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Larger and heated build space for your applications

An even larger, heated build chamber ensures components of the highest quality. It includes a heated build chamber that can maintain a temperature of up to 200 °C.

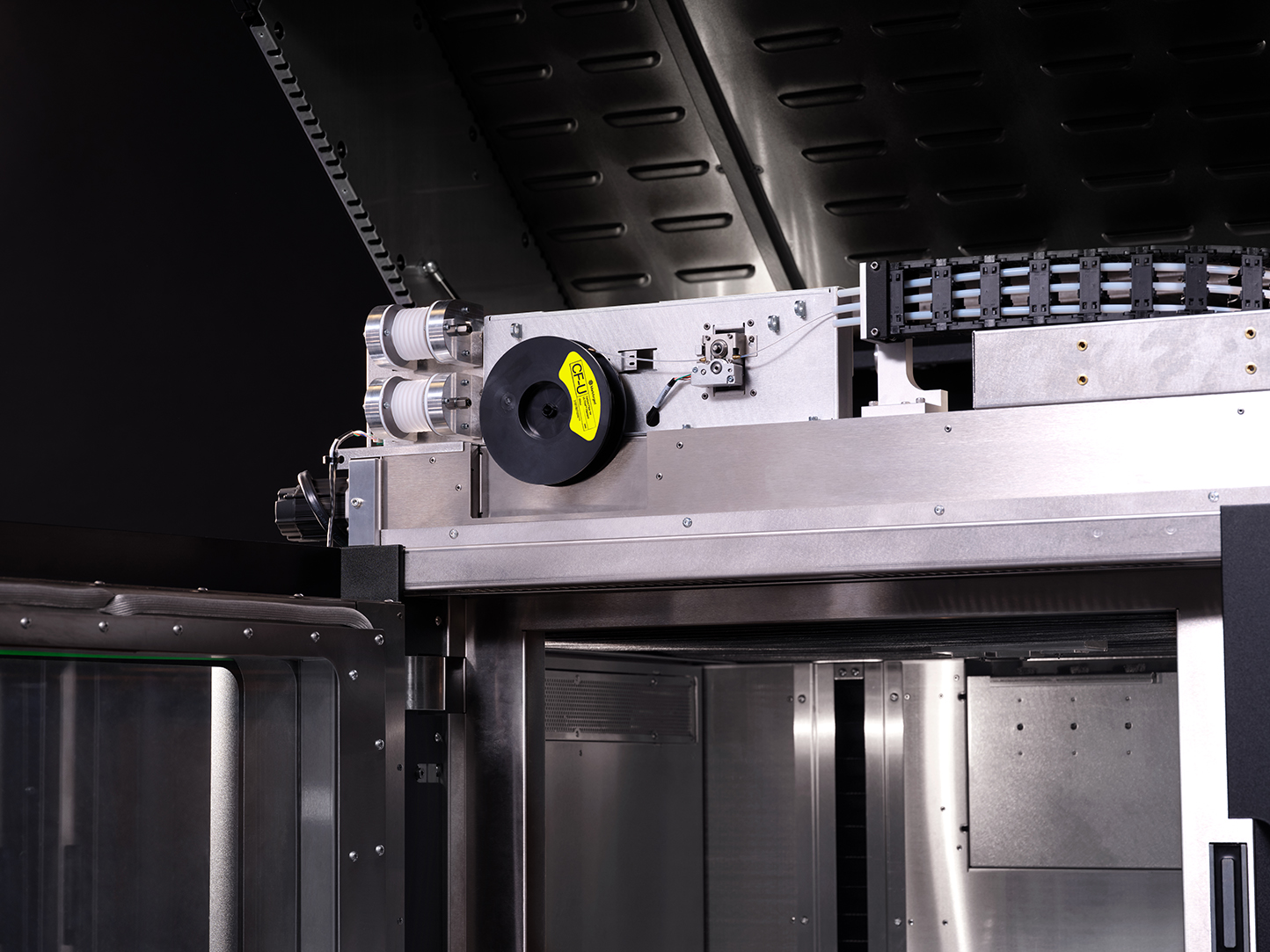

Prints up to 8 times faster than the standard print settings of Markforged's existing composite printers.

– Large material spools with 3200 cm²

– 3 nozzle print head

– Precision-ground vacuum bed

– Reusable printing sheets

– Touchscreen interface

Massive components, even faster

The FX20 combines size and productivity to produce significantly larger parts incredibly fast. The build volume is nearly 5x larger than other Markforged printers. And the completely redesigned motion and extrusion systems enable high-speed 3D printing without compromising quality.

The Markforged FX20 is also a precise, sensor-controlled machine that offers the highest reliability and is easy to operate. Fully integrated storage and handling keep materials dry during printing, while sensors fully monitor the extrusion system. Linear

Touchscreen interface

The Markforged X7 3D printer features a built-in touchscreen that makes it easy to control the Wi-Fi connection, start printing, and manage the printer.

The Eiger Software

An innovative, stable, and above all, easy-to-use platform designed to relieve the user of as much work as possible. Furthermore, the EIGER software is cloud-based, meaning it's always up-to-date. You upload 3D print jobs from your PC to the cloud-based EIGER software via your browser. The 3D printer can be controlled via LAN cable, USB, and Wi-Fi. The software allows you to manage and catalog your STL files.

Thanks to the simple operation, you can intelligently equip your component interior with support structures and completely automatically equip the selected region of the component with the continuous fiber layer by layer. The fiber density can be adjusted per layer using a simple slider in the software. This allows you to design and print your component perfectly to your force application.

The printing process can be paused to embed components into the print. This allows you to integrate electronics, sensors, and ball bearings into your part.

We also offer an optional offline version of EIGER. An additional fee applies.

Do you have any further questions?

Write us a Email or use the Chat.

You can also call us on 07361 63396 00.

Here you will find the complete article overview.

Reviews

There are no reviews yet.