Description

Markforged Mark Two (Onyx) – Robust printed components in every office

The Markforged desktop 3D printer series was designed to enable every designer and engineer to produce stable components and functional parts in the shortest possible time. The three most important components—hardware, software, and material—harmonize perfectly, offering you a unique 3D printing experience. You can determine the material and stability of your components yourself, and the Mark Two then produces perfect functional parts from your CAD data. Let the desktop series inspire you, too.

Produce functional components of the highest quality with the 3D printer:

- Highest strength, stability and rigidity of the print results

- Production in the shortest possible time for prototypes and small series

- Easy operation of the powerful EIGER software for processing your CAD data

3D printers for functional parts that are exposed to high loads

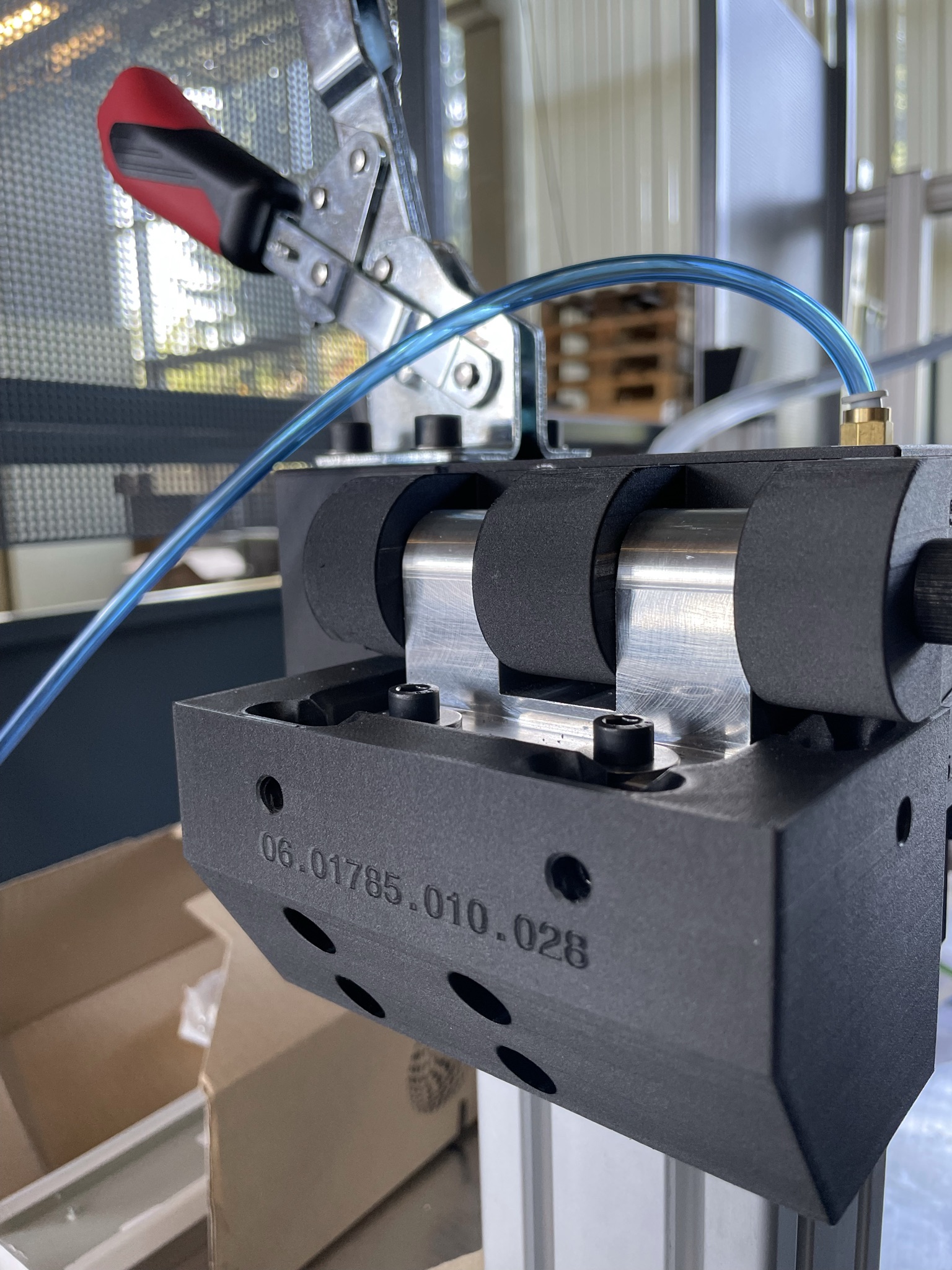

The Mark Two 3D printer was developed to overcome the strength limitations inherent in many 3D printing materials. The Markforged Mark Two 3D printer is the world's first 3D printer to print composite materials. Now functional parts, tools and fixtures can be printed with a significantly better strength-to-weight ratio.

The fundamental difference in the stability of a component is the continuous fibers of a component printed with carbon fiber, glass fiber, or Kevlar®. However, the carbon fiber component is only optimally designed to withstand tensile and compressive forces if the carbon fiber (or carbon fiber) is uninterrupted. This is why the continuous fiber is so crucial for the stability of a component printed with carbon fiber, Kevlar®, or glass fiber.

The basic principle of the 3D printer is FFF (Fused Filament Fabrication) printing technology. This involves printing the outer contours in nylon material, while the interior of the component is covered with continuous carbon fibers, Kevlar®, and glass fibers. The 3D printer actively switches between two nozzles during the printing process to produce astonishingly robust fiber-reinforced plastic parts in a single build. This printing technology with continuous fiber materials is called Continuous Filament Fabrication (CFF™).

For further information, please visit the Product information page.

Precision, quality, design – new generation 3D printing

The manufactured components impress with excellent surfaces thanks to their maximum strength, stability and rigidity in various materials.

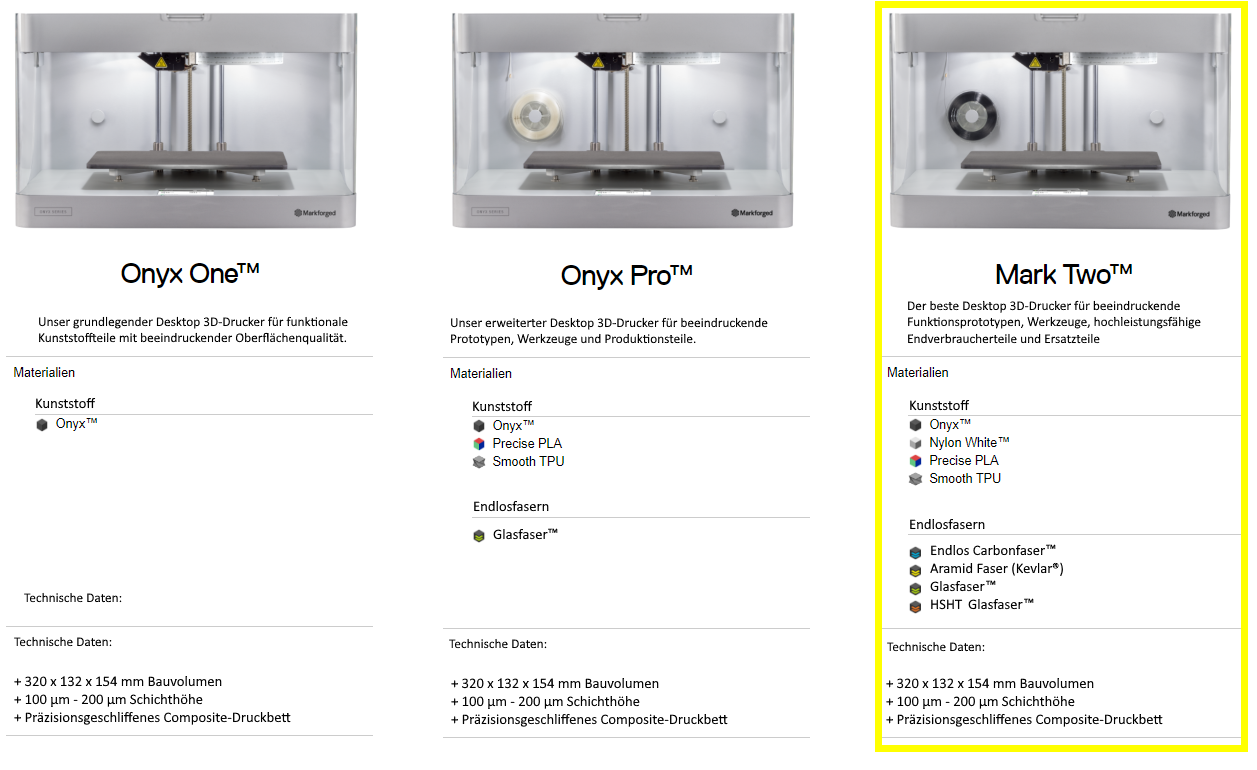

Compare the industrial 3D printers in our Markforged Desktop series

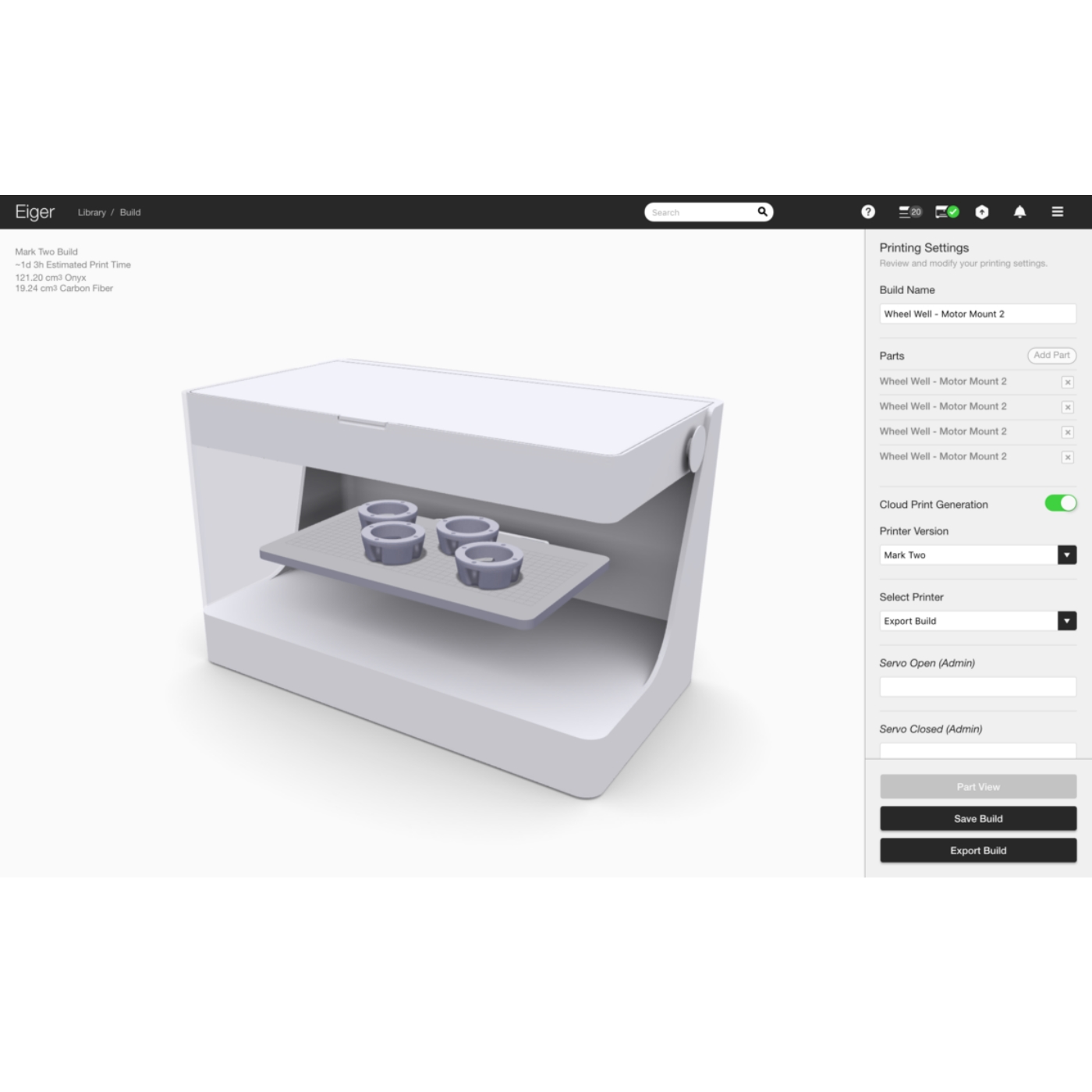

The Eiger Software

An innovative, stable, and above all, easy-to-use platform designed to relieve the user of as much work as possible. Furthermore, the EIGER software is cloud-based, meaning it's always up-to-date. You upload 3D print jobs from your PC to the cloud-based EIGER software via your browser. The 3D printer can be controlled via LAN cable, USB, and Wi-Fi. The software allows you to manage and catalog your STL files.

Thanks to the simple operation, you can intelligently equip your component interior with support structures and completely automatically equip the selected region of the component with the continuous fiber layer by layer. The fiber density can be adjusted per layer using a simple slider in the software. This allows you to design and print your component perfectly to your force application.

The printing process can be paused to embed components into the print. This allows you to integrate electronics, sensors, and ball bearings into your part.

We also offer an optional offline version of EIGER. An additional fee applies.

SCOPE OF DELIVERY

- 1x Mark Two Onyx 3D printer

- 1x including 1 year all-round carefree package

- 1x construction platform Desktop Series True Bed

- 1x Onyx FFF filament 800cm³ roll

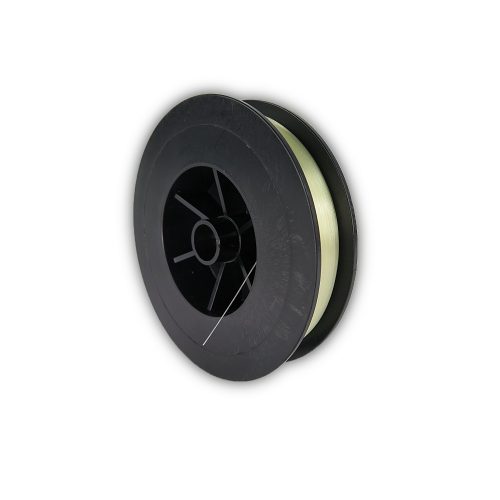

- 1x Glass Fiber CFF Filament 50cm³ Roll

- 1x Kevlar CFF filament 50cm³ roll

- 2x carbon fiber 50cm³ wheels

- 1x high-temperature glass fiber 50cm³ roll

- 3x FFF replacement nozzle

- 3x CFF replacement nozzle

- 1x drying box

- 1x tool set

Do you have any further questions?

Write us a Email or use the Chat.

You can also call us on 07361 63396 00.

Here you will find the complete article overview.

Reviews

There are no reviews yet.