Markforged PX100™ - fast and precise

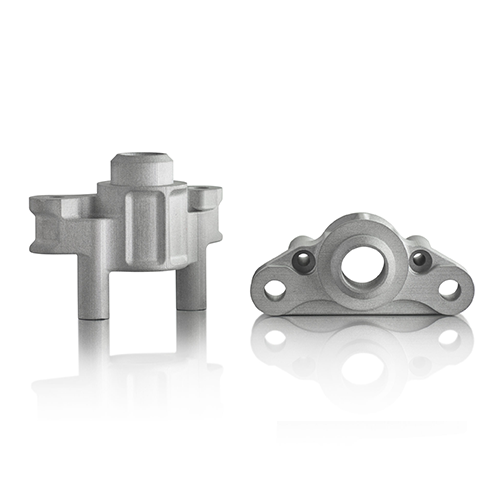

Additive manufacturing of metal components with new precision.

The PX100 binder jetting system is a game changer and enables series production of everything from industrial components to medical and consumer goods.

The PX100™ system from Markforged

The powerful PX100 offers speed, precision and adaptability and makes the additive manufacturing of metal components even more interesting for more and more applications.

The PX100 is a game changer in binder jetting technology, enabling serial production of everything from industrial components to medical and consumer goods. Manufacture complex, production-ready parts where the components will be used.

Outstanding productivity

Printing system with a static accuracy better than 1µm!

- Printing capacity of up to 1,000 cm3 per hour

- Print head with 70,400 nozzles working with 2pL droplets at 15.5 kHz

- Easily exchangeable powder magazine for quick material changes

installation space:

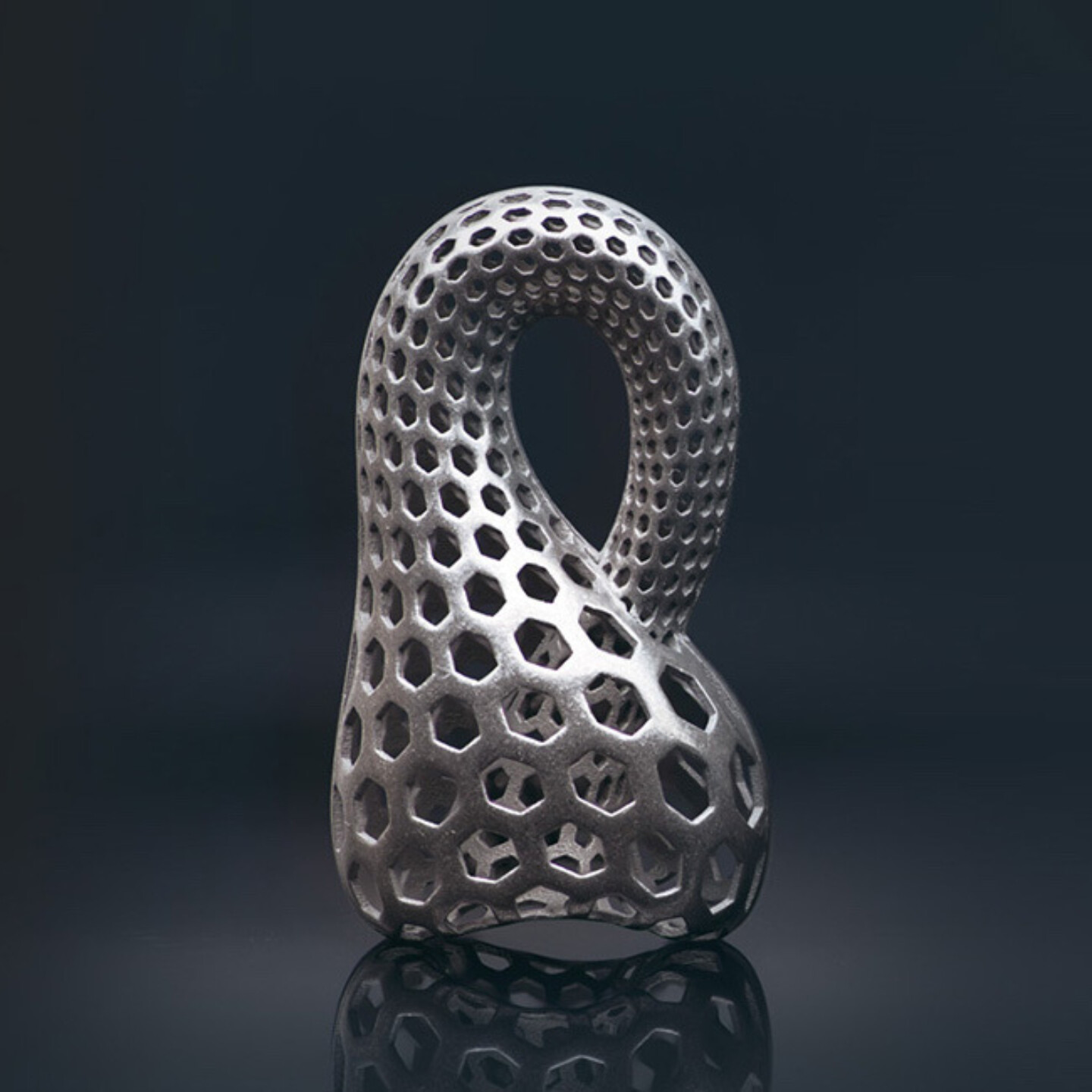

Design freedom

PX100 is ideal for manufacturing components with complex geometric structures, intricate internal details and even integrated parts. With PX100 precision, you can produce metal components that were previously difficult - or even impossible - to manufacture.

No support structures are required. This minimizes post-processing and increases productivity. Almost 100 % of excess powder is recycled! Produce large quantities of different or individual parts without complex tools and with minimal material consumption.

The drive system

Since 2003, the focus has been on precision and speed.

To ensure precision and accuracy in the long term, the drive is provided by linear motors and air bearings instead of belt drives and screws. All moving parts have an accuracy of 1µm. This combination ensures excellent stability and repeatability. The applicator applies uniform layers of powder precisely and the resolution is excellent: 8000 x 1600 DPI! The result is reliable, detailed components, time and time again.

Alloy 625

625 is a nickel-based superalloy. They are weldable superalloys suitable for high-temperature applications in aerospace, for example.

Would you like a demo, do you have any questions or do you need a quote for the Markforged PX100 3D printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.