Challenge

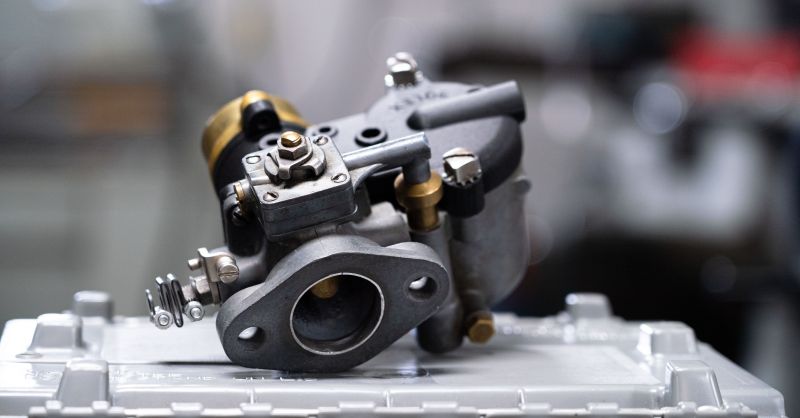

Robert Ginsburg, Chairman of RPG Industries, is constantly seeking innovative ways to expand the business and bring new expertise in-house for his clients. One such client—D&D Classic Automotive Restoration—was restoring a 1930s classic car when they discovered that one of the original carburetors was broken. They conducted a worldwide search for a replacement part but couldn't find one. D&D then attempted to repair the existing part; however, the original couldn't be welded or soldered because it required an airtight and watertight seal.

“Trying to manufacture this part from scratch would be prohibitively expensive,” says Ginsburg. “The detail, complexity, and internal components of the part make it nearly impossible, and the machined part will never look as good as the original,” Ginsburg explains.

Solution

Robert had been considering integrating a metal 3D printer into his company for some time; however, he was only familiar with powder-based printers, which are not economically viable and can pose potential workplace hazards. When he realized that the Markforged Metal X 3D printer fit his budget and was a safer option than other powder-based metal printers, Robert knew he had found his solution. He purchased the Metal X system and a Mark Two 3D printer and put them into operation immediately.

Robert initially used his Markforged Mark Two 3D printer to print the replica carburetor cover using Markforged Onyx material (a thermoplastic with shredded carbon fibers).

“The ability to quickly scan a broken part, make the repairs, and print it was a game-changer for us,” says Robert. “And the ability to change materials in Eiger with little to no effort is just one of the reasons we love Markforged. The car has been fully restored and is now back with its owner, with a fully functional 3D-printed metal part under the hood.”

Request a DEMO component now!

See for yourself how strong the components are.

The future

Robert is extremely pleased with the addition of his Metal X system and has made it a central feature of his business. “The Metal X is the first thing you see when you walk in,” says Robert. “People are quite amazed—it has definitely given us a competitive edge over other EDM competitors.” He hopes that some of the smaller molds and tools they traditionally produce can be printed on either the Mark Two 3D printer or the Metal X before being put into direct use. “I think a lot of our employees were indifferent to 3D printing. They didn’t really understand why I invested in this technology. When they saw the results, I think pretty much everyone understood my reasons for the investment.”

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.