Combining metal and carbon fiber 3D printing to produce prototype surgical tools

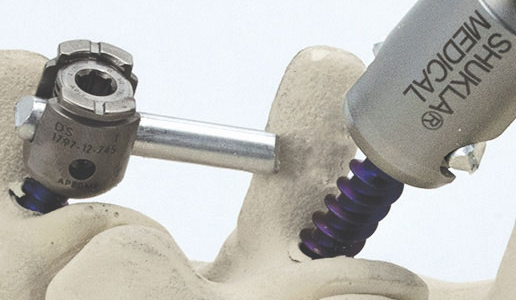

Shukla Medical, a wholly-owned subsidiary of aerospace manufacturer S.S. White Technologies, develops and manufactures universal orthopedic implant removal tools such as the Xtract-All® Spine Universal Spinal Implant Removal System.

Challenge

Shukla Medical products are used by surgeons worldwide to efficiently remove old implants before replacing them with new ones—all while preserving the patient's bone. Most orthopedic implant removal instruments are complicated and time-consuming to operate, whereas Shukla Medical's universal instruments are known for their simple, intuitive design.

Die Produkte von Shukla Medical sind für orthopädische Chirurgen konzipiert und verfügen über zeitsparende Funktionen wie Schnellkupplungen und mehrere Extraktionsoptionen. “Es ist allgemein bekannt, dass jede Minute im Operationssaal sehr teuer ist”, sagte Zack Sweitzer, Product Develop-ment Manager bei Shukla Medical. “Jede Zeit, die Sie sparen können, ist also äußerst hilfreich. Die Kosten für einen Operationssaal können zwischen $35 und über $100 liegen, obwohl sie je nach Krankenhaus und chirurgischem Eingriff variieren. Die Werkzeuge von Shukla müssen schnell als Prototypen hergestellt und von orthopädischen Implantatchirurgen getestet werden, um Form und Passform zu überprüfen, bevor das Endprodukt hergestellt wird. Das Team fertigte die Teile zunächst mit ihrer CNC-Maschine als Prototypen an oder schickte die Entwürfe an einen Dritten, stellte jedoch fest, dass lange Vorlaufzeiten die Wiederholung von Prototypen stark verlangsamten und sie daran hinderten, ihr Produkt schnell auf den Markt zu bringen.

Solution

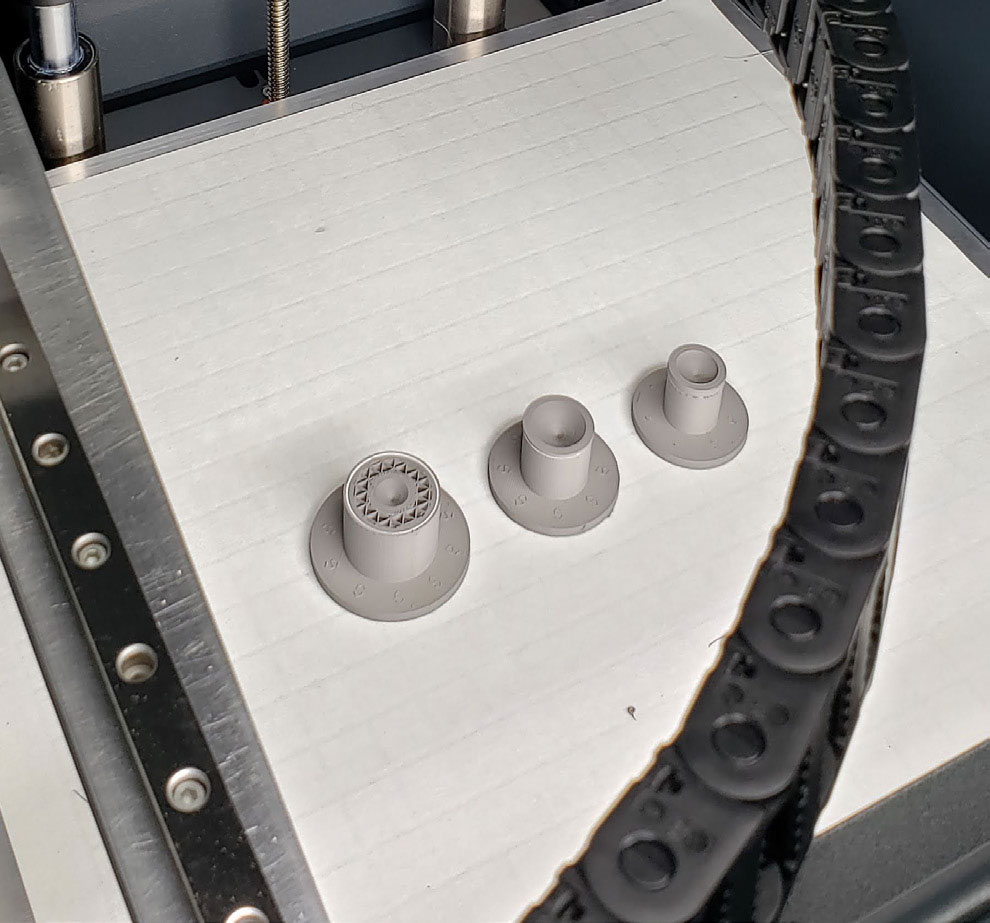

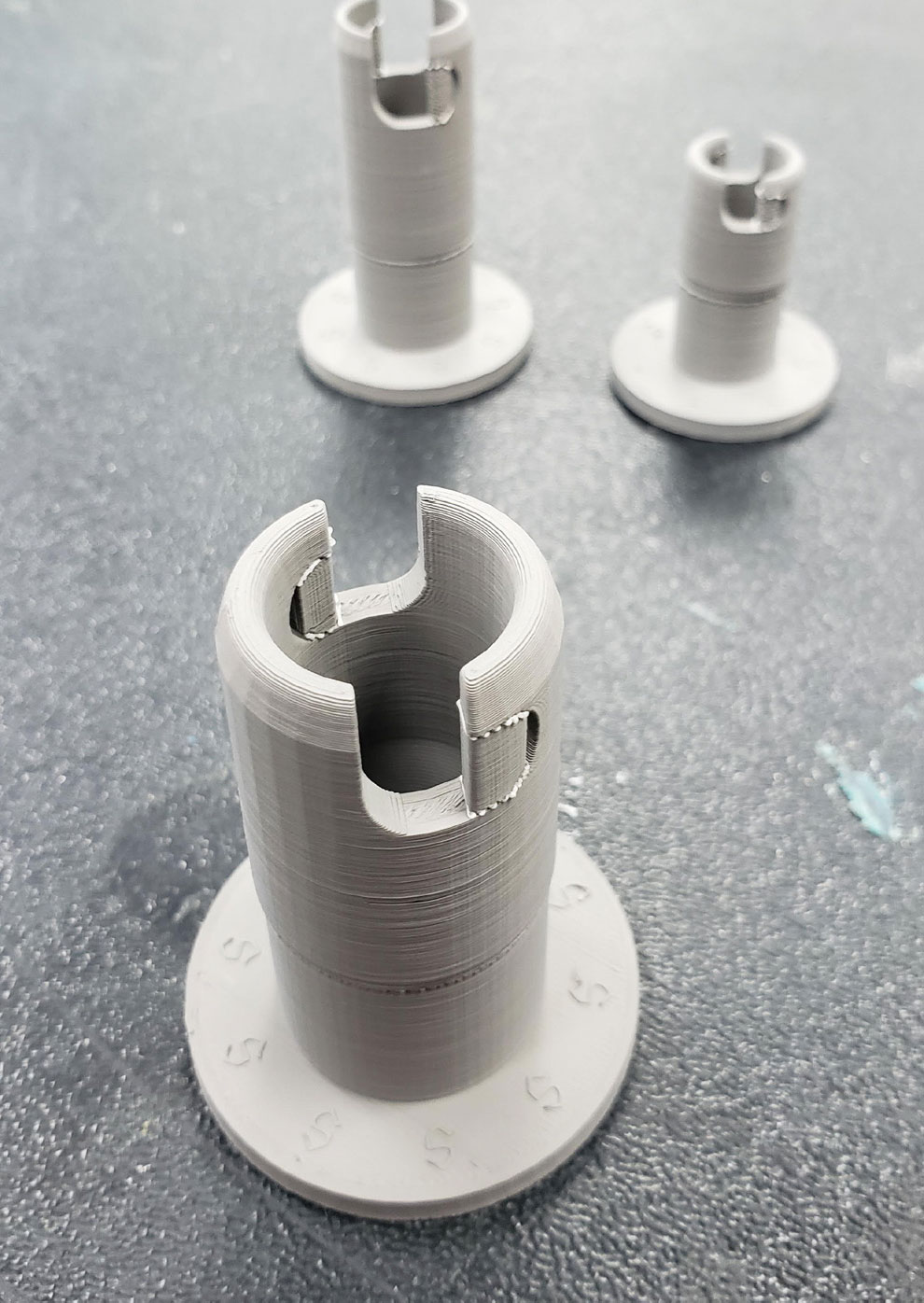

In 2017, Shukla Medical purchased a Markforged 3D printer capable of printing in continuous carbon fiber and began using it to prototype their instruments instead of their CNC machine. It proved to be a fantastic addition to the team's equipment. “We put our instruments through a lot of stress, and the carbon fiber gives them a bit more strength, so they don't feel like toys,” says Adam Gosik-Wolfe, a mechanical engineer at Shukla Medical. But Adam and the team wanted more—they wanted metal prototypes to make it even easier for surgeons to visualize using the instruments. Subramanya Naglapura, VP of Operations at Shukla Medical, also saw the potential and championed the purchase of the Metal X. After a great experience with their Markforged carbon fiber 3D printer, the team decided to add a Metal X system—with full management support.

By using 17-4 PH stainless steel, Shukla Medical was able to produce a prototype from the same material as many of its end products. The company now uses its 3D composite printer for initial prototypes and then the Metal X system for the final prototype, which is then put into the hands of surgeons for evaluation. “The surgeon can imagine using it during the actual incision and tell us if it feels right in their hands,” says Sweitzer. “If we can create a prototype more efficiently and get finished products to market faster, we will remain at the forefront of the industry,” Sweitzer adds. The continuous carbon fiber 3D printer is also used to produce soft jaws for any Metal X parts that require post-processing, making it and the Metal X system the ideal 3D printing solution for the team.

At a glance

Customer testimonials

“Compared to a conventional CNC machine, the Metal X allows you to experiment with more complex shapes or take more design risks.”

– Adam Gosik-Wolfe, Mechanical Engineer, Shukla Medical

“If we can create prototypes more efficiently and bring finished products to market faster, we will continue to be at the forefront of the industry.”

– Zack Sweitzer, Product Development Manager, Shukla Medical

Request a DEMO component now!

See for yourself how strong the components are.

Looking to the future

Shukla Medical has significantly reduced its time to market by using the carbon fiber 3D printer and the Metal X system. Engineers at S.S. White Technologies—of which Shukla Medical is a subsidiary—frequently use the Markforged printers to create tools and fixtures for the aerospace, automotive, and medical industries. “We will be able to bring many more products to market faster with our Markforged printers, and we finally have the design freedom to do so,” says Sweitzer.

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.