Replacing aluminum parts with 3D-printed continuous carbon fiber

– Get to know Markforged in 60 seconds!

Users must be able to rely on the printed components to implement additive manufacturing as a true manufacturing technology in their company. What are your biggest challenges in manufacturing? How do you currently manufacture your equipment such as fixtures, grippers, or holders? We can help you solve these challenges with additive manufacturing.

Why should aluminum components be replaced?

In recent years, a severe aluminum shortage among industry suppliers has led to sharp price increases. Since January 2021, aluminum prices have risen by over 50%, and experts expect this increase to continue over the next two years.

According to experts, the global aluminum shortage is due to increased material consumption, which is caused by three factors: increased spending on consumer goods due to economic stimulus packages, increased investment in sustainable technologies that rely on the use of aluminum (e.g., wind turbines, electric cars), and Chinese production and consumption of aluminum.

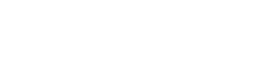

Given this aluminum shortage, Markforged continuous carbon fiber offers a suitable alternative, as many of our customers use it as a replacement for machined aluminum parts. Carbon fiber has the best strength-to-weight ratio among our continuous fiber reinforcements. It is six times stronger and eighteen times stiffer than Onyx and is often used for parts replacing machined aluminum.

When embedded in a composite base material like Onyx, it can create parts as strong as 6061-T6 aluminum. As a material, it is extremely stiff and strong and can be automatically deposited by Markforged 3D printers in a variety of geometries to produce optimized parts.

Economic efficiency of components

It's not about replacing aluminum as a material across the board. That's clear.

The goal is to use additive manufacturing to produce components that previously had to be manufactured mechanically, which was uneconomical. Complex applications or applications that require a high degree of variation and low production volumes can be used to almost completely replace aluminum.

How is this possible?

The components are reinforced with continuous carbon fiber via a second nozzle in the print head!

This means that you get exactly the same mechanically resilient component with every print, which, if required, has higher strengths than aluminum.

What makes carbon fiber an ideal replacement for aluminum?

More and more companies are turning to composite materials like continuous carbon fiber to produce industrial-grade parts quickly and cost-effectively. For years, a compromise between strength, delivery time, and cost had to be struck. Conventional polymers could be manufactured quickly and cost-effectively, but the resulting components lacked significant strength.

A college in the US printed a chain link. This chain link was printed on a Markforged 3D printer and reinforced with continuous carbon fiber. In the tensile test, you can see how the chain link lifts the weight of a 10-ton cement mixer before breaking under the stress.

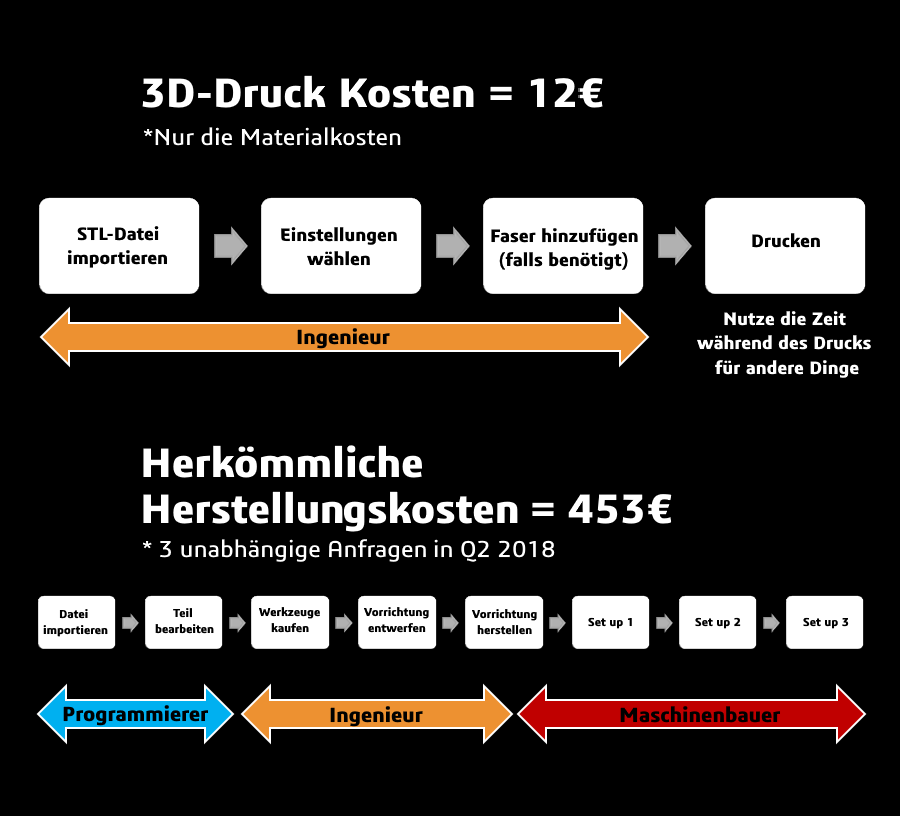

It's not just about being able to 3D print more stably. 3D printing technology and fiber-reinforced plastics should also be used cost-effectively. The following example shows the cost difference between producing a 3D-printed plastic part with fiber reinforcement and a milled aluminum part with the same geometry.

Calculating an excellent return on investment!

The argument for a good ROI (return on investment) for 3D printers has become significantly stronger in recent years. It's becoming increasingly easier to find 3D printers whose costs are justified by the benefits. 3D printing has become an indispensable part of production. It can be used to produce excellent tools and customized components. While the true value of a 3D printer isn't always obvious at first glance, precise calculations reveal a different story.

In manufacturing, productivity is inextricably linked to revenue and performance. High-quality 3D printers may seem overpriced at first, but they can save you a lot of money overall. Many costs associated with traditional manufacturing processes

and increase the ROI accordingly. Examples of this can be found in the production of tools, fixtures, and prototypes.

In our guide "The Economics of 3D Printing," we explain how to calculate your ROI. Download the guide and perform your own calculations, or have your ROI calculated here.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

The economics of 3D printing

The economics of 3D printing has long been a hot topic in busy machine shops. If this is the case for your company, this guide will help you decide whether to purchase a Markforged 3D printer.

In this guide, we summarize the requirements you need to consider when designing components to be manufactured using additive manufacturing.

Simply fill out the form on the right and you will receive the guide immediately.

Fill out our secure form to download the free guide directly.