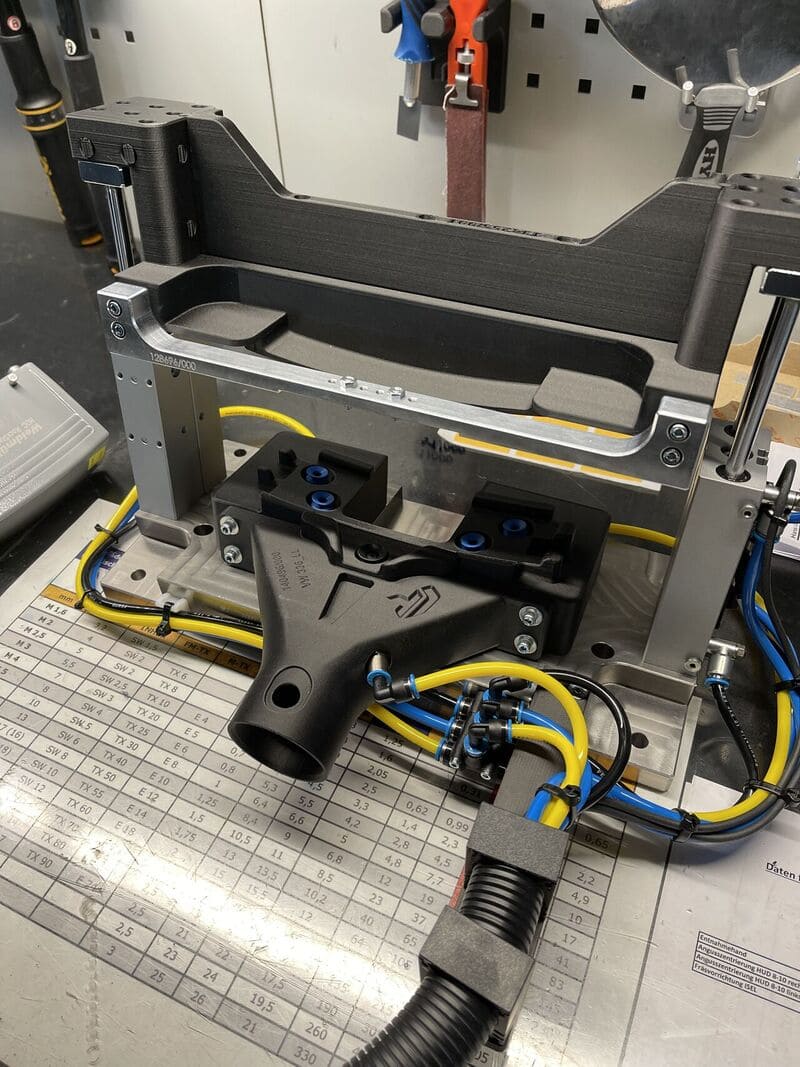

Individual gripping systems from the 3D printer

In the field of automation, gripping systems are often used to add, remove or sort components.

When we think about exercise, we want to lose weight.

So the requirement is: The function of a gripper with the lowest possible weight, high stability and long service life.

How this works ideally is shown by the Robot Technology GmbH!

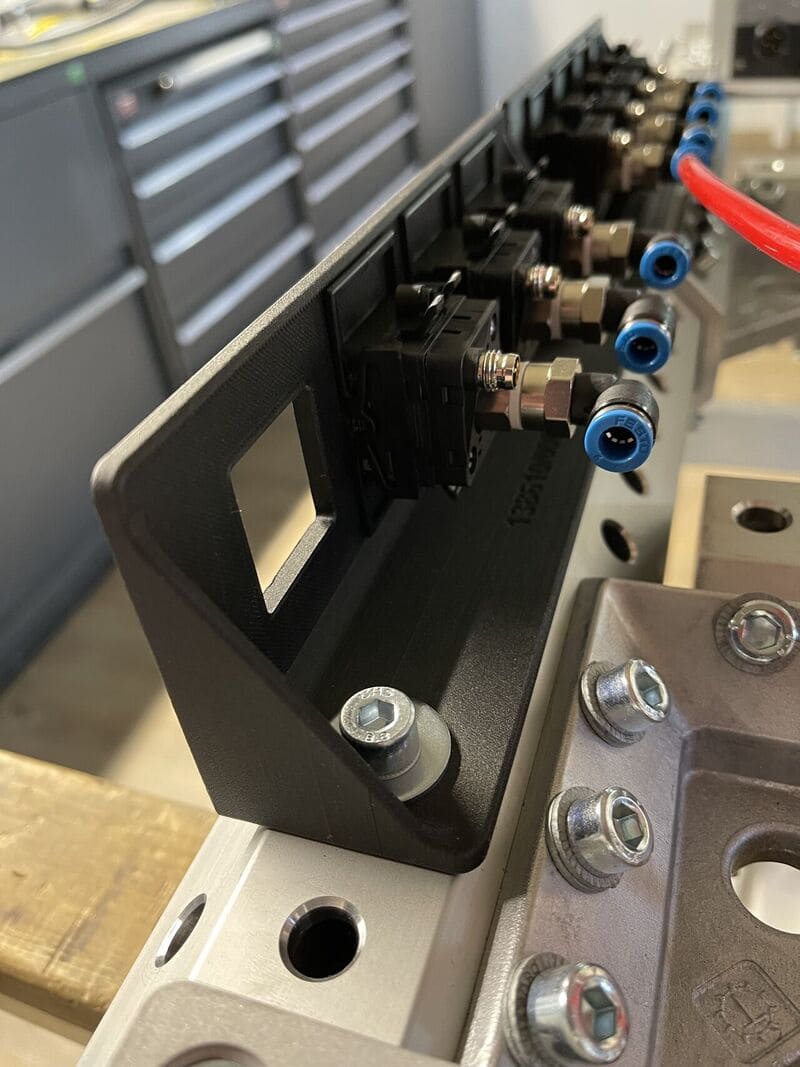

Grippers, fixtures, and other components are already being manufactured additively here. The grippers are printed on a Markforged 3D printer.

This represents enormous added value for our own production as well as for our customers.

Thanks to an integrated continuous carbon fiber, the grippers have enormous strength and can withstand the demands.

Further advantages of 3D printed grippers:

✅ Any type of individual gripper possible

✅ lighter grips – more repetitions

✅ integrated functions possible

✅ Compatible with all common robots

✅ On-demand production – without warehousing

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar