Can 3D printed robot grippers 97% be cheaper?

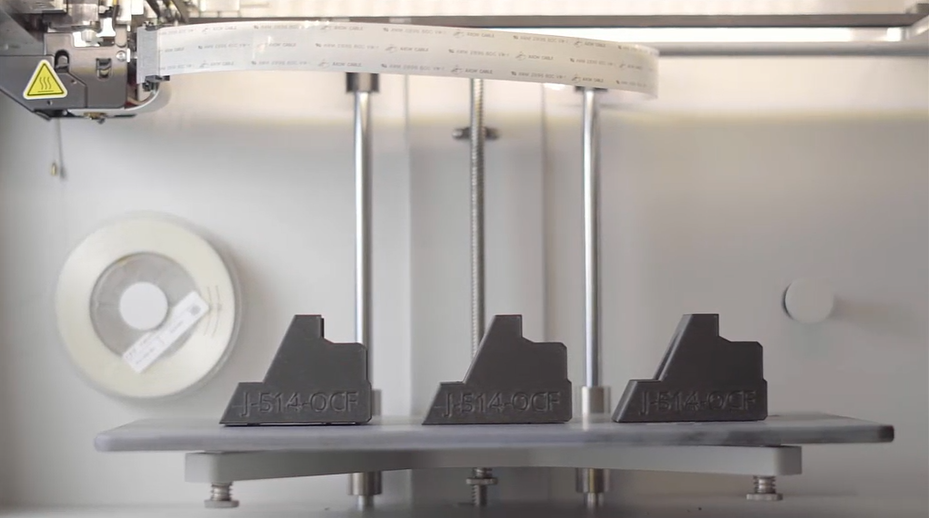

In practice, the economic and physical limitations of conventional manufacturing processes often result in robot grippers that are heavy, bulky, and inefficient – resulting in high costs and long lead times. 3D-printed robot grippers are very robust, yet lightweight, and can be manufactured quickly at a fraction of the cost. Using Markforged's continuous fiber technology, these parts can withstand thousands of cycles without failure. A new set of robot grippers can be produced with the MarkTwo in less than a day and is as strong as aluminum – at half the weight!

Comparison of CNC and 3D printing:

Production time: 93% shorter

Production costs: 97% cheaper

Have you already discovered opportunities for additive manufacturing in your company? Share your experience in the comments.

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

Hinterlasse einen Kommentar