Proof of savings with new ROI tools in Eiger

Return on investment (ROI) is an important metric for evaluating the performance of an investment relative to its cost. Additive manufacturing offers many ROI benefits, such as lower labor and part costs, reduced inventory, avoided downtime, and shorter lead times.

Evaluating ROI is important both before and after a purchase decision:

Before deciding to purchase a 3D printer, estimating the potential ROI helps justify the investment.

After purchasing a 3D printer, estimating the realized ROI provides your company with data to evaluate results and gain support for further investment and expansion.

One of the most important inputs to ROI is part spend—the cost of manufacturing a part—which you can now estimate automatically in Eiger.

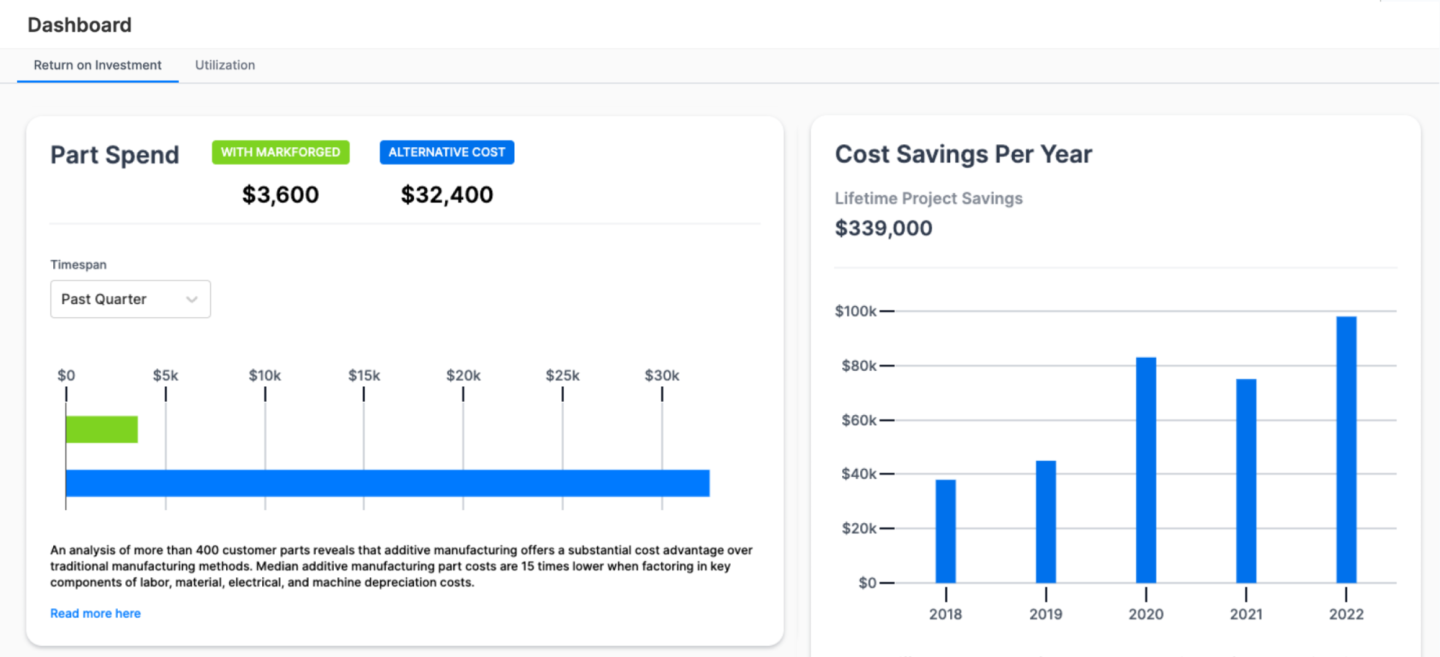

ROI dashboard

Using data automatically collected by Eiger, you can track the cost of producing parts on your Markforged printers and compare it to the cost of producing the same parts using traditional methods. This data is presented in one of two new windows in the ROI dashboard: Parts Expenditure and Cost Savings per Year

Cost per part compares the cost of manufacturing parts using Markforged and traditional methods.

Cost savings per year is the sum of the savings in parts expenditure on an annual basis.

Estimating the cost of printing a single part in Eiger is easy—it's automatically calculated when a part is cut. However, manually collecting, compiling, and analyzing this data across multiple parts, devices, and timeframes is tedious and error-prone. The new ROI Dashboard collects and analyzes the data automatically, without user intervention. Simply go to Eiger and access the ROI Dashboard to see the costs.

What about the cost of manufacturing a part using conventional methods? Estimating this value for even a single part can be very laborious and therefore not feasible for most parts. So how does Eiger estimate alternative manufacturing costs?

How does it work?

There are two values displayed in the Part Expenses window: With Markforged and Alternative Cost.

With Markforged

- This is the cost of producing all parts printed within a given period of time.

- They include parts printed on all cloud-connected printers (offline devices are not included) and by all users in your Eiger organization.

- It is based on the cost per part calculated in Eiger, which is the material cost for the part.

- It includes both completed and aborted prints. Aborted prints are included in the part cost because the material is considered scrap, as it is not reusable.

Alternative costs

- This is the cost of producing all printed parts, but using traditional manufacturing methods such as machining and casting.

- The estimated cost is 10 times the cost of producing the parts with Markforged. This calculation only includes completed (successful) prints in the Markforged cost.

- Where does the 10x factor come from? Data from over 400 customer parts was used to determine the median cost ratio between manufacturing using traditional methods (primarily machining) and manufacturing with Markforged. The median cost ratio for this analysis was 15x—meaning the median cost of manufacturing a part using traditional methods is 15 times the material cost of printing. Because cost calculations are complex and typically based on estimates, a conservative factor of 10x was chosen for the ROI Dashboard.

In summary, the ROI Dashboard in Eiger has two key attributes that provide an initial estimate of how much money your company has saved through your investment in Markforged:

Fully automated – the cost of printed parts across all devices in a customer’s Markforged fleet is calculated without any user intervention.

Estimated alternative manufacturing costs based on reality – a study of over 400 customer parts was used to determine the average cost ratio between traditional manufacturing and Markforged manufacturing.

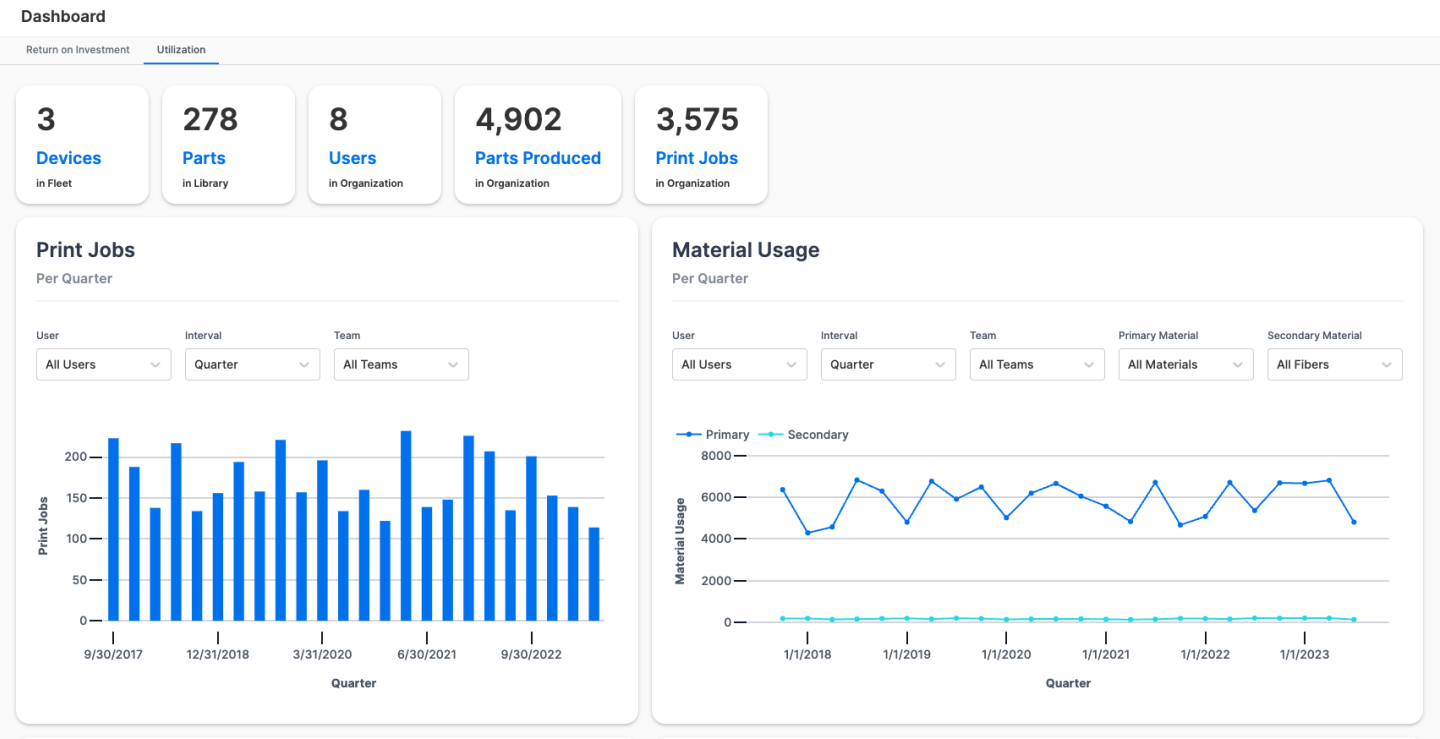

New look for the Utilization Dashboard

The Utilization Dashboard has a new look and feel. It contains all the data you rely on, but with a more user-friendly interface. With metrics on the number of print jobs, material consumption, print time, and printer utilization, it continues to be a great resource for evaluating your fleet's performance.

This is just the beginning

The goal of the ROI Dashboard is to provide you with the data you need to make data-driven, cost-effective decisions for your business. With this dashboard, we're making it easy for you to estimate the savings achieved by manufacturing your parts with Markforged printers—and that's just the beginning. Over time, the ROI Dashboard will expand to include additional metrics, the ability to input known costs like labor and energy costs, filters to isolate a specific device or user, and much more. All of these updates will allow you to evaluate the return on your investment in more detail and with greater accuracy.

Hinterlasse einen Kommentar