Where software meets hardware

At a recent trade show, an employee of a pipe bending company approached Bruce Jones and pointed to the strange device behind him.

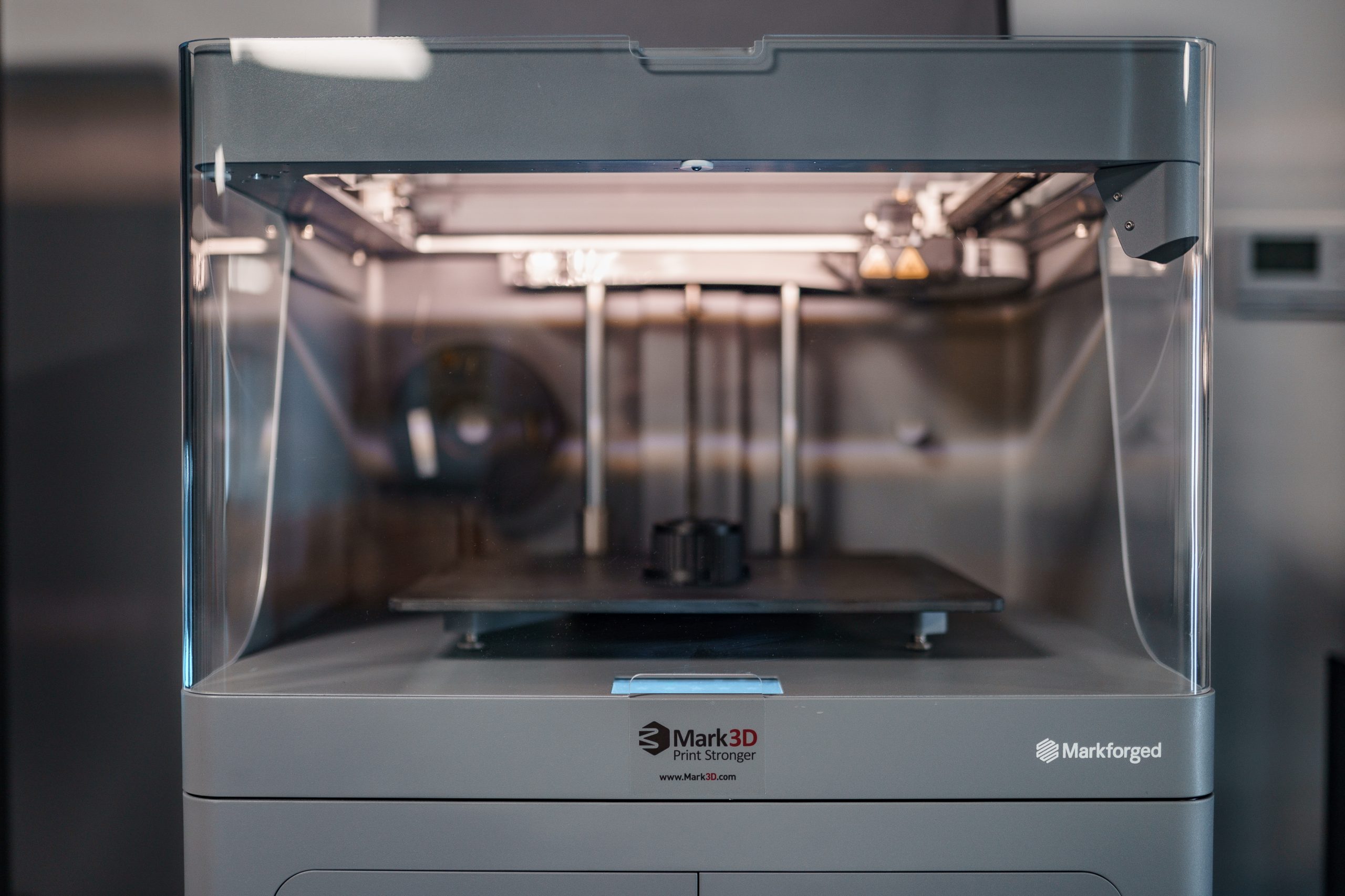

"What is this magical little box?" asked the pipe bender. It wasn't the first time Jones had to answer questions about the impressive 3D printers from additive manufacturing company Markforged.

“You explain the device to them and show them what it can do, and they immediately think, 'Oh, this is actually something that could be very valuable to my company,'” said Jones, a software engineering manager, of the company's metal and continuous fiber 3D printers, which combine the power and speed of agile software development with industrial manufacturing.

While the 3D printing company creates physical objects, it's the software associated with those physical objects that makes working at the Boston-area company so interesting.

"I transitioned from being a mechanical engineer to a software engineer, and it took me many years to realize that a 3D printing company was the perfect outlet for my passion, which lies right at the intersection of software and the physical world," says Jones. "It's a really cool feeling to write code and then see something move—not just on the screen, but in the real world."

Built In Boston sat down with Jones, Director of Product Management Ted Plummer, and Principal Product Manager Doug Kenik to learn more about Markforged's leading digital manufacturing software and how the company empowers its software engineers to work on exciting and complex projects that go beyond the parameters of a traditional SaaS company.

What sets Markforged apart from other 3D printing companies?

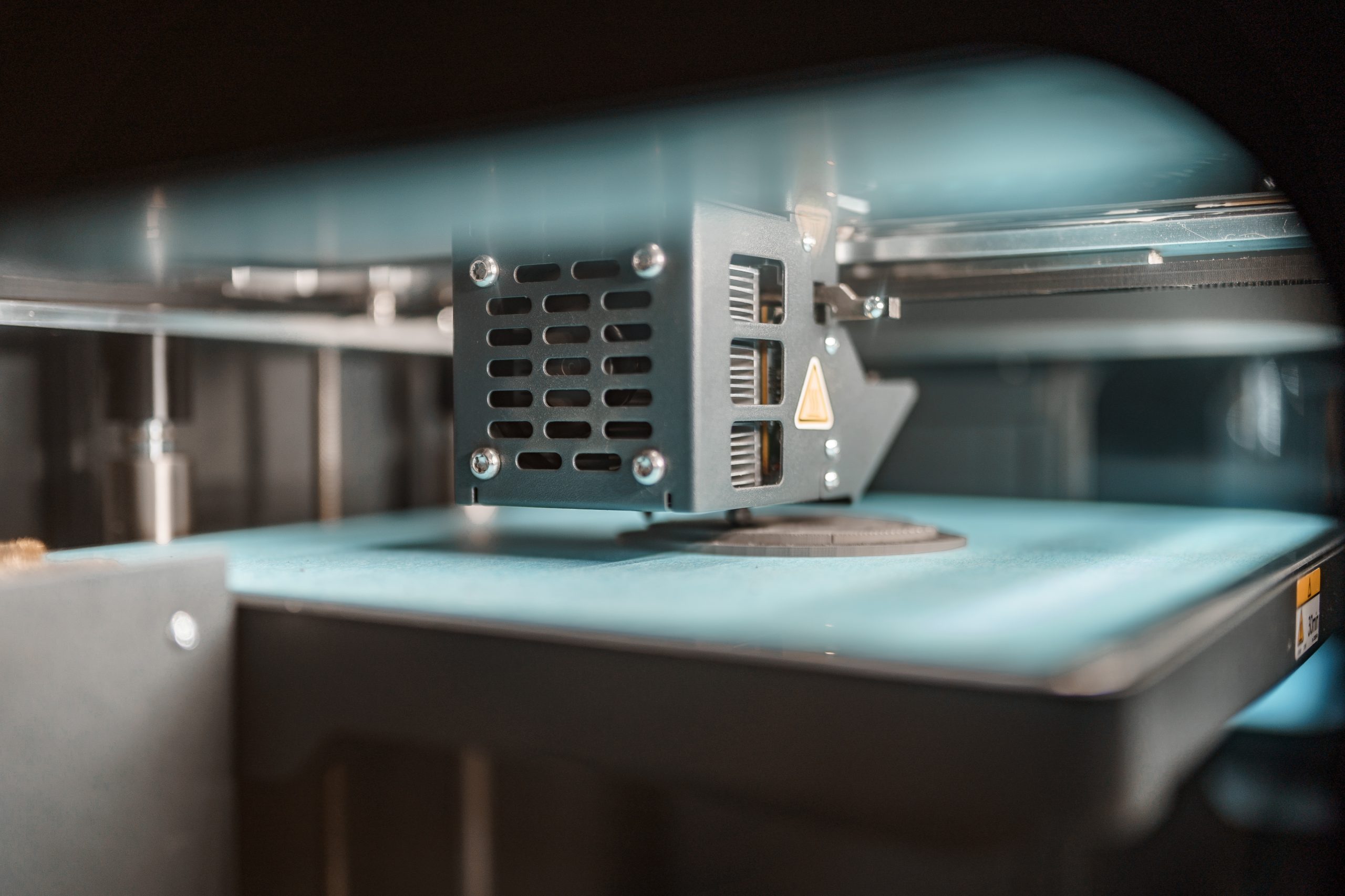

Unlike many other 3D printer manufacturers, Markforged doesn't just use plastic filaments as its printing material. The company's industrial printers are capable of printing continuous fibers into the base material. Available materials include carbon, fiberglass, and Kevlar, each of which is embedded layer by layer into the print. The combination of the base material Onyx, a polyamide 6, and the respective continuous fiber enables strengths comparable to aluminum.

Markforged also offers the ability to print various metals using the FDM process, including Inconel 625, stainless steel, tool steels, and copper.

The company's printers are integrated into factories around the world and have helped transform supply chains by accelerating the production of prototypes and spare parts.

Bruce Jones, Head of Software Development: In the traditional world of manufacturing, you build the product before testing it, and then you realize, "Well, that doesn't quite work. Now I have to make a new one." But with 3D printing, you can make small individual parts, test only those parts, do it 15 times in 15 different areas, and then, when it comes to the actual printing, you can be confident that everything will fit together. It's a very software-oriented philosophy of making things that are enabled by technology.

In software development, you often break a large monolith into individual parts that can then be tested individually. And when I design something for 3D printing, I do exactly the same thing.

Ted Plummer, Head of Product Management: "I always tell people that we're a software company, not a hardware company. We make something that other people can use to create physical objects. Our product is essentially software, even if it manifests as a 3D printer, just as Tesla is a software company that makes cars."

"My favorite thing is when people come to trade shows and ask, 'Why are you better?' And I don't really answer them. Instead, I say, 'Here's our stuff and here's what we do. Walk around and come back at the end and tell me what you think.' Invariably, they come back and tell you all the reasons why we're better: It's the attention to detail, the engineering that goes into the system, the unique approach to security, the materials, the hardware, the software, and the way it all comes together in this vision. I think having all of that in one place is really powerful.

Another additive for the team

Markforged made its first acquisition, Teton Simulation, in April. Teton Simulation's "SmartSlice" technology enables users to automatically validate and optimize part performance based on the requirements of specific use cases. The program enables users to drastically reduce their part scrap and lead times.

In what other ways does the intersection between software and manufacturing manifest itself at Markforged?

Doug Kenik, senior product manager at Markforged and CEO of Teton Simulation: It became clear very early on that whoever would emerge as a top player in the 3D printing space would have to create ecosystems in which their customers are so successful that they literally can't fail. And the only way to achieve this is through software. This was a huge incentive for Teton to join the Markforged family: The focus is on the entire ecosystem, driven by software, making them one of the largest players in 3D printing.

Plummer: If you walk around our office, you'll see mechanical engineers, software engineers, and materials engineers sitting side by side, working together. Regardless of the product we're working on, we can control the software, materials, and hardware, making changes to all components. It's always very interesting to find the right balance between these things.

Is it still exciting to be able to touch the things you make?

Kenik: This makes you very aware of what success means. When you compare it to other software companies, the metrics can seem a little wild or abstract, whereas here you have this tangible thing sitting there, and someone picks it up and their eyes go crazy because they realize what they can achieve. That happens to employees, too. You print something out, pick it up, and think, 'Wow, I can actually do that.'"

Plummer: I was at a trade fair in Italy last week, and I'm still meeting people who say, "Oh man, I didn't know you could do that." They're pushing the boundaries just as hard as we are, and they're still amazed at the things that are possible.

Kenik: This happened to us in Germany. There was a Korean company that makes these extremely high-torque drill bits—the bits at the end of the drill are made of stainless steel—and they came to us and gave us a design file and asked, "Do you think this would work?" Overnight, we printed it and glued it to the end of their drill. They were able to tighten screws with enormous torque using something we had 3D printed. Nobody believes this story. But when you see it, it's kind of magical.

Author: Jeff Kirshman, Built-In, Boston

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar