Manufacture mechanically and thermally resilient components using industrial 3D printing

Choosing the right 3D printing material is also particularly important in additive manufacturing! Which technical properties are particularly important for my application? What do the terms flexural strain, flexural stress, and tensile strength mean? How important are the chemical, mechanical, thermal, or electrical properties of the material?

What actually characterizes a functional part?

By definition, the term "functional" refers to a part's ability to fulfill its design intent. Each of the requirements listed below is a common functional requirement for a 3D-printed part. We've defined each requirement, listed how both short-fiber-filled polymers and CFR meet the requirement, and highlighted which technology has a greater impact. Markforged parts incorporate both technologies, with a short carbon fiber-filled polymer reinforced with continuous fibers.

Important mechanical and thermal properties of 3D printing materials

Functional requirement | Description | Short fiber-filled polymer | Continuous fiber reinforcement |

|---|---|---|---|

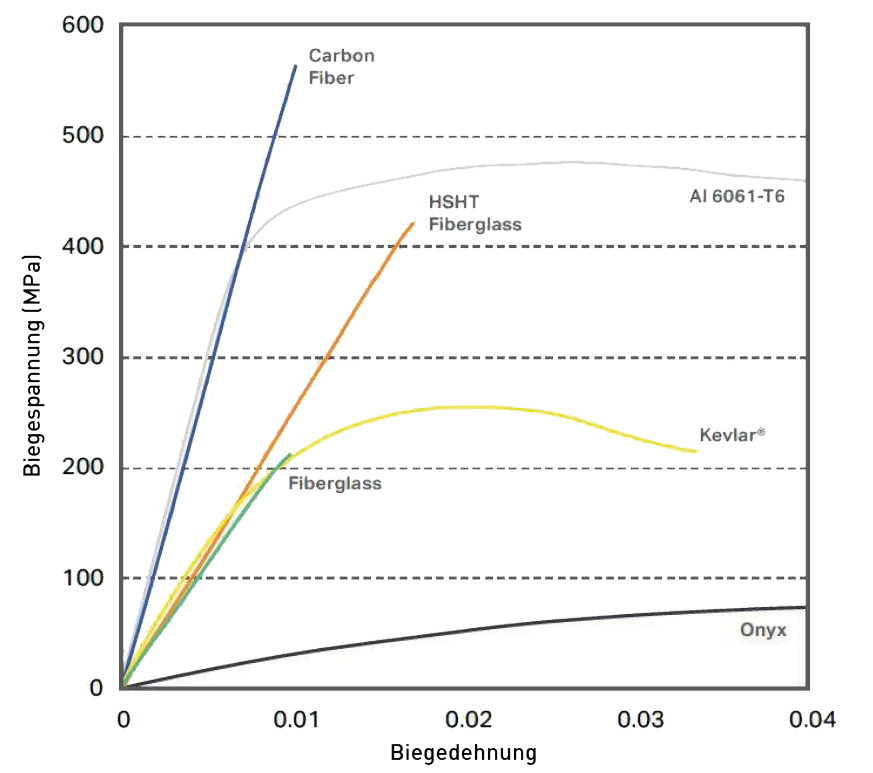

Stiffness | The extent to which a material deforms under load | Short fibers increase stiffness by 1.5 to 3 times compared to conventional polymers. | Continuous fibers increase stiffness by 20 times compared to conventional polymers. |

Strength | Maximum load the material can withstand before it gives way | The addition of short fibers slightly improves the tensile and flexural strength of the materials. | In addition, continuous fibers increase strength by up to ten times. |

Durability, shock resistance | The ability of a material to resist breaking and absorb energy under shock loads | Nylon is known for its durability and resistance to impact. The addition of short fibers further improves wear resistance. | Continuous fibers increase the resistance of parts, so that they deform much later. |

Durability, wear and tear | The ability of a material to resist the gradual removal or deformation of surface material by friction | Short fibers increase the abrasion resistance of the polymers, so they last longer in abrasive environments. | The fiber is only exposed when the outer surface of a piece is worn through - in extreme cases, it can even provide abrasion resistance when exposed. |

accuracy | How close a part is to the toleranced dimensions - both immediately after printing and after some time in use | Short fibers improve the volume drag coefficient of materials, thereby improving printing accuracy and reducing printing errors. | CFR does not affect initial part accuracy, but prevents dimensional creep over time, which is common in plastics. |

Heat resistance | The reaction of a material to elevated temperatures in use | Short fibers help stabilize the material at elevated temperatures and thus reduce warpage. | High-strength high-temperature fibers (HSHT) and other long fibers resist heat much better than matrix polymers, so HDT can rise to 145 °C. |

Resistance to Chemicals | Like a material reacts when it aggressive chemicals exposed to the manufacturing environment are available | Fiber-filled polymers on Nylon base are against the mostly in manufacturing used solutions and Lubricant resistant. | CFR has only a limited Effect, since the fibers in the Rule no chemicals are exposed to. |

Request a DEMO component now!

See for yourself the strength and surface quality of the components.

Thermoplastic for demanding technical purposes

The Markforged base material Onyx

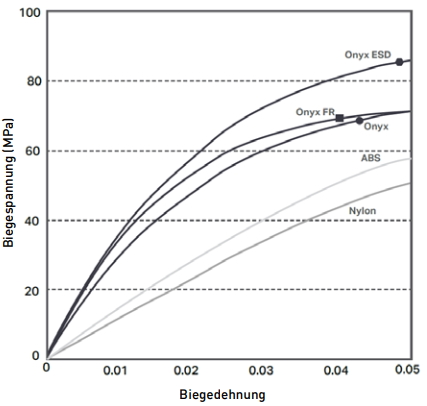

Onyx can be used to produce rigid, strong, and precise parts. Onyx is already 1.4 times stronger and stiffer than ABS and can be reinforced with any type of continuous fiber. Onyx sets new standards for surface quality, chemical resistance, and heat resistance.

Flexural strength 71 MPa

Flexural modulus 3.0 GPa

The Markforged continuous fiber materials

Before we dive into the applications, let's briefly define CFR. CFR is a process that allows 3D printers to reinforce fused filament fabrication (FFF) parts with continuous fibers. A CFR-capable machine uses two extrusion systems: one for conventional FFF filament and a second for continuous fibers with long strands. Continuous fibers are laid out layer by layer, replacing the FFF infill. The resulting parts are significantly stronger (up to ten times stronger than any FFF material) and can replace aluminum parts in the application.

Low hurdle for functional parts

Many 3D printing technologies offer customization and low cost complexity – the big difference with CFR is that this is also possible for functional parts. Compared to parts 3D printed using the FFF process, parts created using CFR offer unique advantages and properties, such as:

By producing functional parts, CFR 3D printers reduce the distance between engineers and the core of production in several important ways:

How are functional requirements mapped to applications?

"Functional" is not a singular term in manufacturing – different applications have different functional requirements. Below, we map the functional requirements that 3D printing fulfills to common applications. We have summarized the requirements in Critical and Recommended where critical means a requirement met by almost all parts in that application, and recommended means a less important or universal requirement. It is important to note that there is diversity even within specific applications.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar