In traditional manufacturing, pure copper is a difficult material to process: Its ductility often leads to deformation in subtractive manufacturing processes. Therefore, subtractive manufacturing often has to make do with copper alloys that have lower electrical and thermal conductivity.

Pure copper is also generally a difficult material for 3D printing. Metal AM technologies such as powder bed fusion (PBF) often rely on copper alloys because pure copper reflects when interacting with lasers. However, unlike subtractive manufacturing and many other metal AM technologies, metal fused filament fabrication (FFF) is ideally suited for printing pure copper.

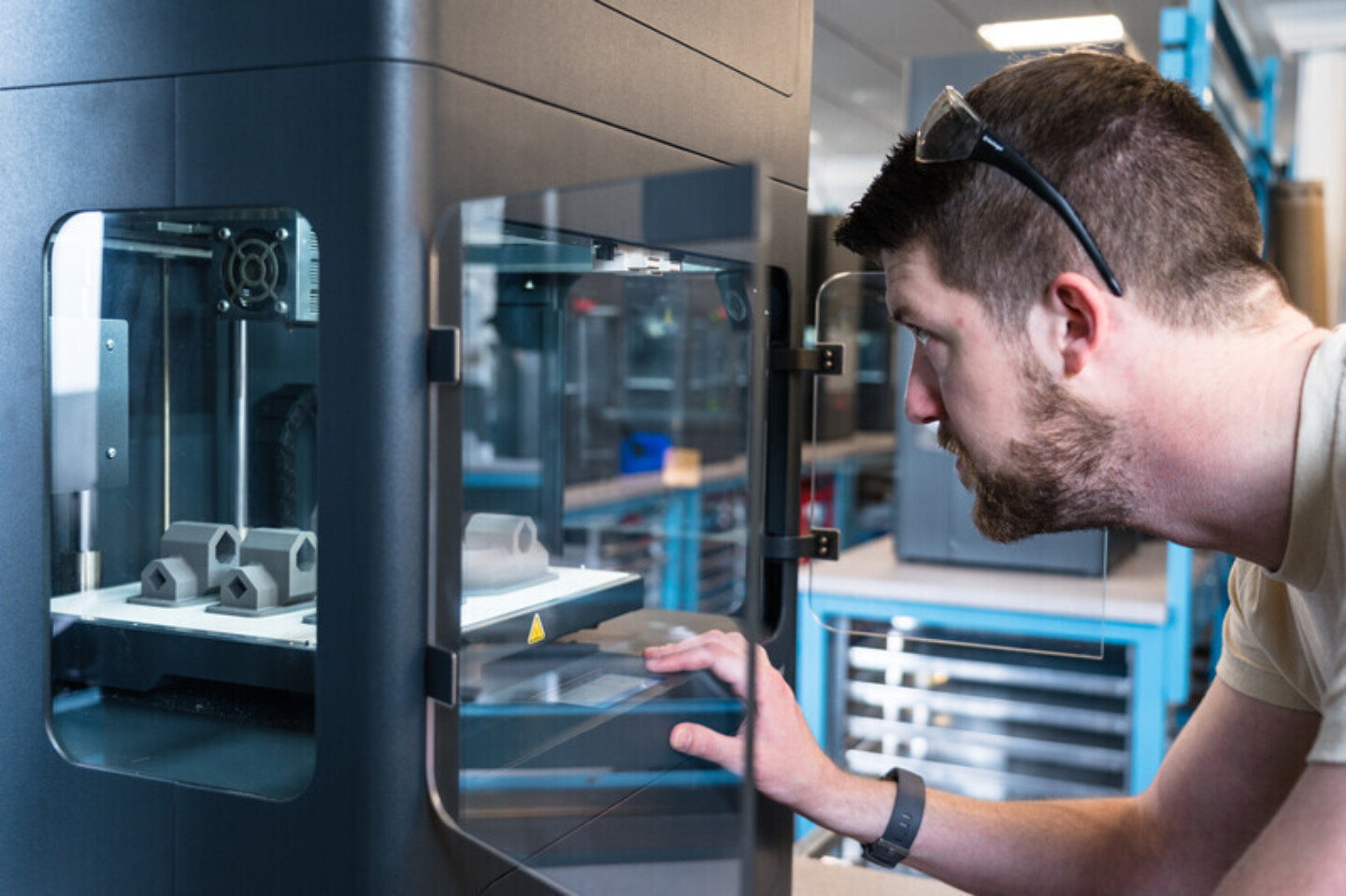

With the new Fine Features print setting for pure copper, you can use your Metal X system for an even wider range of applications – without the complications of machining pure copper or the need to settle for an alloy. In exchange for longer print times, Fine Features offers users the ability to improve the print quality of pure copper parts on the Markforged Metal X No special nozzles or other hardware modifications are required; Metal X users will automatically have this capability added to their machine.

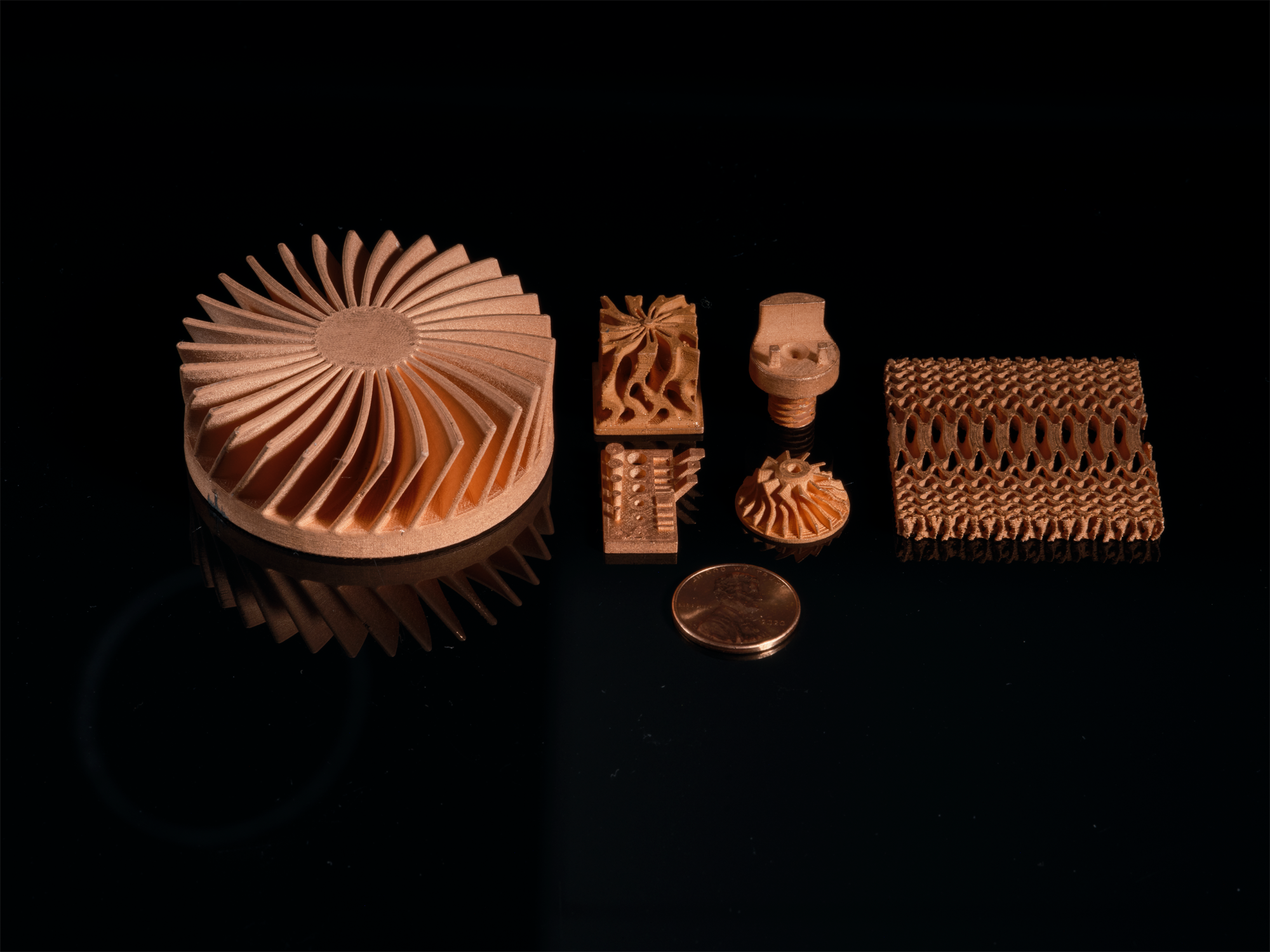

The Metal X can combine the optimal properties of pure copper while enabling greater design freedom to achieve complex geometries that would be either impractical or even impossible to produce with subtractive manufacturing. Read this blog to learn about the ins and outs of the new Fine Features print setting, the applications it opens up, and why Metal-FFF is the ideal technology for printing pure copper.

Fine Features: even more copper applications on the Metal X

Fine Features is now available in our Eiger slicing software as a new production-ready setting for pure copper printing, without requiring any hardware changes. Fine Features appears as a new layer height option. Behind the scenes, however, our engineers have been tweaking nozzle temperatures, extrusion rates, and various geometry-dependent offsets to provide an optimized user experience, unlocked via an over-the-air (OTA) software update. Print quality is drastically increased at the expense of longer print times (typically ~30 t/min).

You can use this setting to achieve a smoother surface, higher dimensional accuracy, smaller feature sizes, and greater strength between layers. The ability to print small and intricate features in copper results in higher performance in thermal and electrical applications, opening the door for Metal X users to further process improvements, cost reductions, and shorter lead times.

Why print pure copper on the Metal X system?

AM vs. subtractive manufacturing. In subtractive manufacturing processes, pure copper It is notoriously difficult to machine. Its high ductility often leads to deformation.

While additive manufacturing inherently offers ever-increasing design freedom, the introduction of Fine Features in the Metal X enables a level of design freedom unprecedented in FFF 3D printing. This allows users to achieve a level of part optimization that would be either impractical or simply impossible with subtractive manufacturing.

Metal X compared to other metal AM processes. Unlike many other metal AM processes such as powder bed fusion (PBF) or direct metal laser sintering (DMLS), the Metal X system's ability to print pure copper is not compromised by the material's high reflectivity.

In metal AM processes that use lasers—such as Powder Bed Fusion (PBF)—pure copper is only printable to a limited extent due to its reflectivity, so copper alloys often have to be used instead. The Metal X system is also significantly more cost-effective: The investment of several hundred thousand dollars is only a fraction of the millions of dollars required for a PBF machine.

Applications

The Metal X System is designed to produce complex parts in low volumes on an accessible, cost-effective, and user-friendly platform. Engineers print pure copper on the Metal X System to 1) streamline design validation with rapid prototyping, 2) support production with tooling applications, and 3) produce custom end-use parts for additional applications.

Some common applications for pure copperthat our customers produce on the Metal X are:

Thermal properties:

Electrical properties:

When should I machine my part and when should I 3D print it?

The decision whether to machine or 3D print a part should be based on the desired level of performance optimization.

While machining processes limit the shape of parts, the design freedom of 3D printing allows the creation of complex geometries that can optimize the functionality of an application.

Conformal cooling channels can be incorporated into a design to create turbulence and optimize cooling. Complex lattice geometries can be engineered to maximize the surface area-to-volume ratio, optimizing heat transfer for rapid cooling. For designs that must fit into a compact assembly, complex features can navigate tight spaces to reduce the form factor.

About the Metal X System

The Metal X system is the most accessible, end-to-end 3D printing solution for functional metal parts. It is significantly safer, more affordable, and easier to use than alternative metal 3D printing processes. With the Metal X, users can produce complex industrial parts in as little as one day.

The Metal X system uses an additive manufacturing process called Metal FFF (Fused Filament Fabrication). Metal FFF integrates metal injection molding (MIM) processes with the FFF printing process for plastics and composites. FFF 3D printers extrude a spool of filament through a hot nozzle to additively build a part layer by layer. Filaments are available in a variety of sizes and materials, from prototype plastics to industrial thermoplastics to metals.

Metal FFF can be used to print a wide variety of metals, including tool steels, stainless steels, pure copper, and superalloys such as Inconel 625. The filament consists of a formulation of metal powder bonded with polymer and wax, similar to MIM feedstock. Instead of being injected into a mold, the filament is extruded through a heated nozzle to form the part layer by layer. After printing is complete, the next two steps follow the same process as MIM: chemical debinding and sintering in a protective atmosphere furnace.

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

![[Podcast: Factory of the Future] Is 3D printing a business case for every factory?](https://www.mark3d.com/de/wp-content/uploads/2023/08/fabrik-der-zukunft-500x383.png)

Hinterlasse einen Kommentar