What is additive manufacturing?

The term additive manufacturing, also known as 3D printing, describes a manufacturing process in which physical 3D objects are produced by extruding material layer by layer to create the desired shapes. Additive manufacturing is used for a wide range of industrial applications, such as tool and accessory construction, prototype development, design and the production of end consumer parts in small batch sizes. For manufacturers, additive manufacturing opens up new possibilities and offers innovative solutions in the field of manufacturing processes.

Where does this name come from?

3D printing differs fundamentally from conventional subtractive manufacturing processes, in which objects are shaped by removing material. The product is created by removing material, for example by milling an alloy to produce a screw or hinge. In contrast, 3D printers work by adding material layer by layer to create different shapes. Traditional subtractive manufacturing is known for its slow speed, high costs and limitations in terms of shaping. In contrast, additive manufacturing offers fast, cost-effective and automated processes that open up new possibilities.

Difference between 3D printing and additive manufacturing

Although "3D printing" and "additive manufacturing" are often used interchangeably, there is an important difference between them. The term "additive manufacturing" mainly refers to the use of 3D printing in industrial manufacturing processes.

The distinction between 3D printing and additive manufacturing is important, as the 3D printer market includes a wide range of devices that are more cost-effective and suitable for low-volume production. These devices are usually used as a complement for prototyping or for specific applications, but are less used in high-end industrial manufacturing processes. It is important to note that they do not offer the same performance and precision as additive manufacturing devices designed specifically for industrial purposes.

How does the technology work?

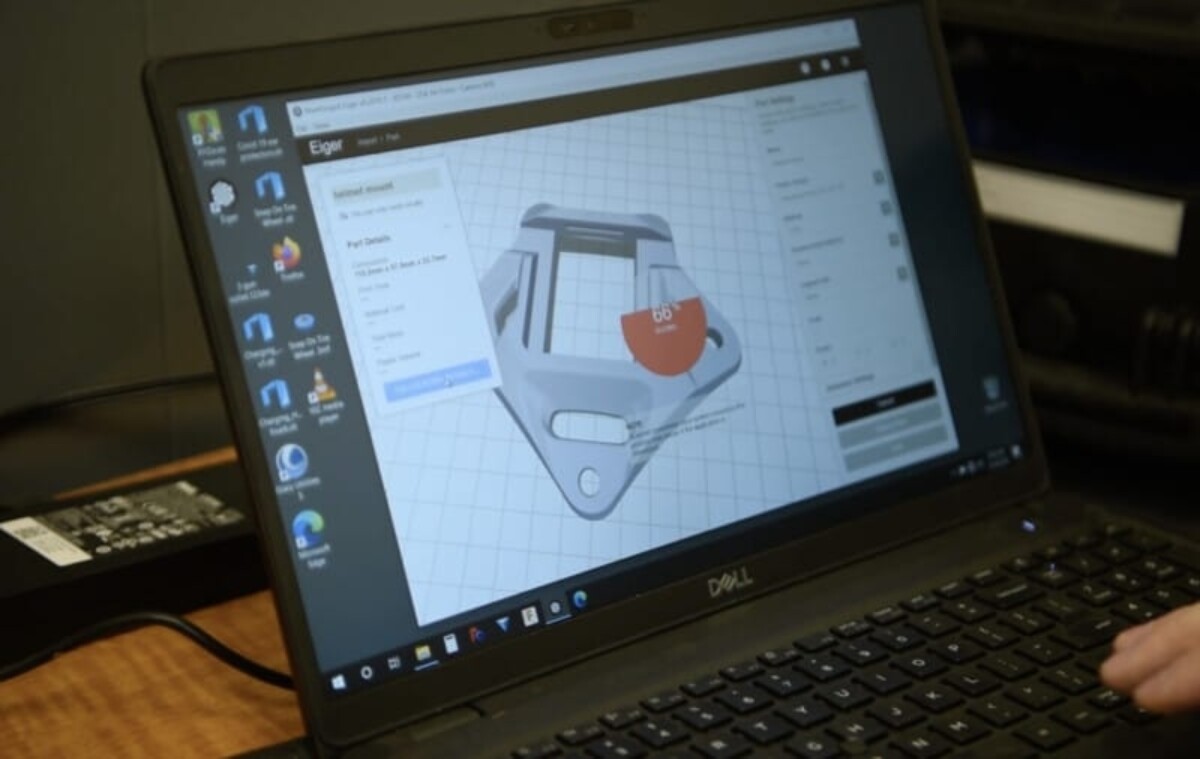

Additive manufacturing converts digital input, such as computer-aided design files of industrial parts, into physical 3D objects.

Once a user has a digital CAD file for their parts, they can export the design to the common STL format, which is specifically designed for 3D printing. The user then loads the STL file design into slicer software specifically designed for additive manufacturing. The slicer software takes the STL file and adapts it to the individual settings for the desired part and printing process. This generates the necessary instructions for the 3D printer to produce the part layer by layer.

In addition, APIs allow the 3D printing software to be integrated into existing factory systems such as ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System). This facilitates the seamless connection and automation of processes in order to make workflows more efficient and effective.

In the 3D printing process, the printer uses the manufacturing instructions received to determine the movement patterns in which the filament is extruded. The print head is precisely programmed to move along both the horizontal (X-Y) and vertical (Z) axes and deposit the material at specific points in the XY and Z coordinates as instructed by the 3D printing software. The 3D printing process builds objects layer by layer, starting from the bottom layer. Each horizontal layer is applied on top of the previous layer.

In additive manufacturing with plastics, 3D printers generally use spools of filament that are extruded in layers to build the objects. The filament is heated until it becomes a molten plastic that can be precisely placed through a small nozzle.

In contrast, additive manufacturing with metals works differently to 3D printing with plastics. Here, metal powders are typically used as the printing material, as metals cannot be extruded due to their high melting temperatures. The extrusion system of a 3D printer cannot be in contact with molten metal for a long period of time. Therefore, the metal parts are first printed in powder form and then transformed into a uniform solid metal part through a high-energy process such as laser sintering or melting in a furnace. This process makes it possible to produce complex metal parts with high precision.

One exception here is the metal FFF process from Markforged. This works very similarly to the plastic process and will be discussed in more detail later.

Which materials can be printed?

The choice of materials in additive manufacturing depends on various factors such as the desired material properties and the requirements of the project, including size, time, cost and temperature resistance. However, there are three main categories of materials that are considered reliable options in today's modern additive manufacturing: Plastics, Metals, Composites.

What plastics are there?

A variety of plastics are used in additive manufacturing, which vary depending on the application and requirements. These range from low-cost materials for prototypes, which offer a certain flexibility and elasticity, to high-performance thermoplastics such as ULTEM™ 9085 filament. The plastics are usually supplied in the form of spools that are suitable for use in 3D printers. Below is an overview of the most common plastic materials used in additive manufacturing today.

nylon is a versatile plastic material that is both flexible and robust and is highly resistant to impact and chemical influences.

PLA (polylactic acid) is an inexpensive thermoplastic material that is often used for rapid prototyping. It is characterized by its easy handling and good printability.

TPU (thermoplastic polyurethane) is a flexible and impact-resistant material with a rubber-like texture. It is particularly suitable for applications where high elasticity and resistance are required.

ABS (acrylonitrile butadiene styrene) is another inexpensive plastic. Compared to PLA, ABS is somewhat softer, but lighter and more durable. It is well suited for use in functional prototypes and end products.

ULTEM™ 9085 Filament is a high-performance thermoplastic that has been specially developed for demanding applications. It is characterized by its exceptional durability, temperature resistance and resistance to chemical substances. It is often used in areas where the highest quality and performance are required.

The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Which metals can be printed?

There are a variety of metal materials that are commonly used in this process. Some common metals are listed below:

17-4PH stainless steel is a widely used metal with a wide range of applications in industrial manufacturing.

A2 and D2 tool steel are special cold work steels that have an exceptionally high hardness after heat treatment.

H13 tool steel on the other hand, is a hot-work tool steel that retains its material properties even at high temperatures.

copper is often used in applications where heat and electrical conductivity are of great importance, as it conducts these better than other metals.

Inconel is a high-quality nickel-chromium superalloy that is ideal for demanding applications due to its excellent resistance to corrosion, high temperatures and chemical influences.

What are composites and what types are there?

A few FDM printers have the ability to produce composites that combine plastics and reinforcing fibers to improve the strength, durability, stiffness and heat resistance of the parts produced. Typically, the following fiber materials are used in combination with plastics to produce composites:

Carbon fiber is ideal for applications that require high strength, as the strength-to-weight ratio is approximately 50 % higher than aluminum 6061. It has a similar modulus of elasticity to aluminum, but its stiffness is 24 times higher than that of ABS. Flame-retardant carbon fibers are often used in the aerospace, automotive and transportation industries.

Kevlar® Aramid fibers are ideal for applications that require exceptional resistance to wear, impact and shock.

Fiber optic is a versatile, high-quality fiber that can be used cost-effectively. It has three times the strength and eleven times the stiffness of ABS.

HSHT (high-strength, high-temperature glass fiber) retains its characteristic properties compared to other fibers, even under extreme conditions at very high temperatures of up to 200 degrees Celsius.

What are the advantages of additive manufacturing?

Advantage 1: Make or buy

When companies decide to outsource their core manufacturing competencies to external partners, dependencies arise with regard to the tools, accessories and equipment needed to manufacture the end product. As a result, manufacturers lose control and are faced with higher costs, longer production times and less transparency. In addition, solving quality issues and other challenges requires more time and coordination. By producing parts in-house using additive manufacturing, companies can better protect their intellectual property, proprietary innovations and other trade secrets.

Advantage 2: More efficient costs

Compared to traditional subtractive manufacturing, additive manufacturing is generally much more cost-efficient. By 3D printing production tools, manufacturers can realize significant savings by eliminating the cost of machining on a monthly basis. Most manufacturers can realize an almost immediate return on investment within a few months or even weeks by using additive manufacturing platforms.

Advantage 3: Design freedom

Traditional manufacturing processes often reach their limits when it comes to the production of parts. Take, for example, a bracket that is produced using a subtractive process. Certain limitations are unavoidable here, as a metal sheet must first be bent or punched into the required shape.

In contrast, additive manufacturing offers the freedom to bypass such steps and restrictions. With 3D printing, designs can be implemented directly without having to rely on these previous steps. In addition, 3D printing enables the production of complex geometries that would not be feasible with other manufacturing processes.

Advantage 4: Improved throughput times

The time required for the entire process from design to manufacture of a part in additive manufacturing is only a fraction compared to subtractive manufacturing processes. When 3D printers are available, the timeframe that would normally take several months to source a part can be reduced to just a few hours or days. This allows for significant time savings from identifying the need for a particular part to actually providing it.

Advantage 5: Shorter time-to-market

Access to in-house additive manufacturing significantly shortens design cycles as prototypes can be produced much faster. Each individual part can be produced in a fraction of the time that would normally be required for traditional manufacturing processes, including inquiry and delivery.

Advantage 5: Strengthened supply chains

By implementing a 3D printing platform, companies gain comprehensive control over their entire supply chain, from start to finish. Manufacturers are no longer dependent on external suppliers to the same extent and thus reduce the risk in their supply chain to a minimum.

Advantage 6: More innovation

For engineers looking for a job, companies investing in an additive manufacturing strategy offer an exciting opportunity to focus on innovation and solve compelling design problems. At the same time, they allow engineers to automate time-consuming and tedious tasks and bypass the cumbersome limitations of traditional subtractive manufacturing processes.

Engineers who have access to in-house 3D printing technology no longer spend time on time-consuming procurement activities such as creating drawings, submitting purchase orders and running tender processes with multiple suppliers. Instead, they can focus their energy directly on creative and challenging tasks.

Possible disadvantages of 3D printing

Disadvantage 1: Small batch sizes

Although 3D printing is a cost-effective option for producing parts in small quantities, the unit costs of additive manufacturing increase significantly when it comes to producing large quantities. The economic benefits of 3D printing are particularly evident for smaller production quantities, while other manufacturing methods may be more cost-effective for larger quantities.

Disadvantage 2: Throughput capacities

In the past, throughput capacities in additive manufacturing were limited due to speed and size constraints. However, manufacturers have now introduced several new 3D printers that can fulfill these requirements.

Disadvantage 3: Integration of software

There are often limitations to the integration of software in additive manufacturing. The software platforms are often specific to certain manufacturers and are difficult to integrate into different production environments and machines. There are only a few providers that offer reliable API integrations into existing factory systems.

Disadvantage 4: Cost of the material

The materials that are suitable for 3D printing can be more expensive than the same material in conventional formats. This is due to the complex manufacturing processes required to shape the materials into a form that is suitable for additive manufacturing.

Current status of 3D printing

Additive manufacturing technologies have been commercially available since the 1980s, but since then both the industry and the technologies have evolved significantly. Early 3D printers were not capable of printing consumer-grade parts, so they were mainly used for rapid prototyping.

Today's platforms for additive manufacturing differ from earlier 3D printers in various ways:

- HardwareCurrent 3D printers are characterized by significantly better speed, performance, reliability, part strength and print quality.

- Connectivity with Industry 4.0Today's additive manufacturing uses the digital technologies of Industry 4.0, such as cloud computing, data analysis, the Internet of Things (IoT), automation tools and software integration. These technologies are applied directly to the manufacturing process.

- Compatibility of print materialsCurrent additive manufacturing platforms work with a wider range of materials, including various high-performance composites and metals. These new materials enable applications in new sectors and industries.

- ISO/IEC 27001Selected platforms for additive manufacturing have standard certification (ISO/IEC 27001), which guarantees strict standards for data protection, data security, confidentiality, integrity and controls. This ensures a high standard of security for the handling of data in additive manufacturing.

Companies that use 3D printing

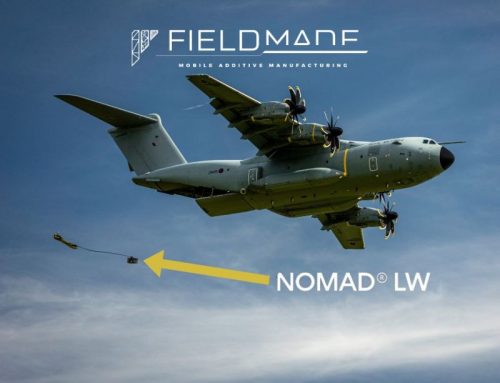

AerospaceMajor original equipment manufacturers in the aerospace industry use additive manufacturing in their production processes. This technology enables them to optimize their supply chains by printing strong and lightweight end-use parts for aircraft and producing tools quickly and cost-effectively.

Consumer goodsAdditive manufacturing is increasingly being used to produce end-use parts for products such as audio equipment and electronic devices.

DentalDentists and orthodontists use additive manufacturing to produce dental models, dentures, braces and dental splints.

EducationLeading universities are integrating additive manufacturing into labs, makerspaces and as part of their engineering curricula to educate the next generation of scientists, engineers and makers.

EnergyLeading energy suppliers are using 3D printing to produce parts that make the production and maintenance of wind turbines faster, easier and more efficient.

Federal and defense ministriesGovernment agencies such as the U.S. Air Force and the U.S. Army use additive manufacturing to accelerate research and development and solve supply chain problems. They can print critical parts for end use on site, even if they are in remote locations.

Industrial equipmentIndustrial manufacturers are using additive manufacturing to produce customized tools that shorten time-to-market and print end-use parts for various types of machine systems.

MedicineMedical device and equipment manufacturers 3D print a variety of parts to meet critical supply chain needs. This ranges from tourniquet clamps to the manufacture of personal protective equipment in the fight against COVID-19.

ScienceScience and laboratory technology manufacturers use additive manufacturing to produce 3D parts for various laboratory automation systems.

The different manufacturing processes

All the different additive manufacturing technologies have the same purpose: the production of 3D objects from CAD designs by extruding material layer by layer. However, there are many different approaches. Additive manufacturing comprises various processes, each of which has specific advantages and disadvantages

- Fused Deposition Modeling (FDM)

In Fused Deposition Modeling (FDM®) or Fused Filament Fabrication (FFF), thermoplastic filament is extruded layer by layer to form the object. This process is characterized by its cost efficiency and the ability to produce parts with high strength, low weight, dimensional stability and thermal tolerance. However, the resulting parts can potentially be anisotropic, i.e. their strength can be uneven in different directions.

- Binder Jetting

Binder jetting creates parts from powdered materials by spreading layers over the print bed and then using a liquid binder to solidify the powder. The advantages of this process are speed, precision and cost efficiency. Several parts can be produced simultaneously in one printing process. However, the resulting parts have a lower strength compared to other additive metal manufacturing processes.

- Stereolithography (SLA)

Stereolithography (SLA) uses layers of a photosensitive liquid plastic that is cured by UV laser radiation to produce a part or object. SLA works well when precision, detail, complex shapes and equipment costs are important. However, with larger parts there is a risk of warping and the resulting objects have limited strength.

- Selective laser sintering (SLS)

In selective laser sintering (SLS), a laser is used to sinter and fuse a fine powder material layer by layer. The advantages of SLS are precision and isotropic strength, i.e. the strength is the same in every direction. However, the costs for machines, maintenance and trained personnel are high.

- Direct metal laser sintering (DMLS)

Direct metal laser sintering (DMLS) or selective laser melting (SLM) uses a laser to melt metal powder and build up an object layer by layer. The advantages are stable mechanical properties, a large selection of available materials and reproducible results. However, purchasing and operating the equipment requires expertise and the process to achieve precise and functional parts is often time-consuming.

- Metal Fused Filament Fabrication (Metal FFF)

Metal Fused Filament Fabrication (Metal FFF) involves the layering of plastic-bonded metal powder, which is then converted into metal by debinding and sintering. This process offers a wide range of available materials, cost efficiency, accuracy and the use of bonded powder. However, the printed parts have a triangular infill and are not solid.

- Digital light processing (DLP)

Digital light processing (DLP) is similar to SLA, but with DLP printers the entire layer is cured simultaneously with a projected light source. The advantages are speed and precise production of complex designs. A disadvantage is the strong odor during the printing process and the risk of warping on larger parts.

- Directed energy deposition (DED)

In directed energy deposition (DED), metal parts are built up using a laser. The material is applied through a nozzle and then melted with a laser or electron beam. The advantages are the ability to produce large metal parts and add material for repair. However, the cost of equipment is high and trained personnel are required.

- Electron Beam Melting (EBM)

In electron beam melting (EBM), metal powder is melted with a high-energy electron beam in a vacuum chamber. This process is characterized by the speed, accuracy and strength of the parts produced. However, it requires well-trained personnel.

- Multijet Printing (MJP) or Material Jetting (MJ)

In multijet printing, droplets of photoreactive material are applied in layers and solidified with UV light. This process makes it possible to use several materials and colors in one part. The disadvantages lie in the strength and durability of the printed parts.

Overseas or overnight?

Supply chain bottlenecks pose a critical threat to the smooth running of production in today's era. Recent supply chain bottlenecks are impacting businesses worldwide, which are facing unprecedented challenges in sourcing essential components. Without the ability to quickly manufacture the required parts in-house, delays in the manufacturing process can occur. The delays depend on how long it takes to manufacture, ship, transport and receive the part. These delays can often take several months.

The use of on-site additive manufacturing gives companies full control over their supply chains. Individual printers can be set up in different geographical locations. Parts stored in a digital inventory in the cloud can then be sent to any 3D printer in the network. The right parts can be printed quickly and accurately, exactly where and when they are needed, with significantly shorter lead times than traditional manufacturing.

For parts that require machining, engineers can ensure that the machined part delivered months later will perform as expected by using an additive manufacturing system for rapid prototyping.

3D printing and Industry 4.0

Additive manufacturing has evolved significantly over the last 5 to 7 years and is now a far more effective manufacturing technology. This can be attributed to two main reasons: Firstly, 3D printing machines have been significantly improved in terms of speed, performance and reliability, and secondly, the advancement of Industry 4.0 technologies has changed the interaction between humans and these machines.

Industry 4.0 is essentially the comprehensive digitalization of the manufacturing industry. This term encompasses the industrial use of technologies such as data analysis, artificial intelligence (AI), cloud computing, the Internet of Things (IoT), augmented reality (AR) and virtual reality (VR), as well as Automationand they play an important role in the concept of the "smart factory".

Additive manufacturing is a technology that has emerged from the Industry 4.0 concept. It enables the digital design and production of parts and automates the manufacturing process. However, the application of other Industry 4.0 technologies to additive manufacturing is also changing the way people can use their 3D printers and this has implications for the future of automation in the industry.

1. Data:

A variety of advanced 3D printers act as data collection centers, gathering information during the manufacturing process and storing large amounts of data in the cloud. This data is used by AI algorithms to optimize and enhance automated decision making and improve print quality.

2. AI:

3D printers can use cognitive technologies to optimize various manufacturing processes. These include:

- Hardware optimization to increase print speed and quality

- Decision-making support to identify which parts offer the greatest business value and which specific parts are best suited for printing with different additive manufacturing processes

- Automatic creation of tools or devices

- Simulation of the behavior of parts under certain loads even before the actual printing process

3. Cloud computing:

Cloud computing allows companies to store part files in digital inventories, print to any 3D printer connected to the network, automatically receive software updates and access the AI-powered features of their printers.

4. Analysis:

The analysis of the collected data provides manufacturers with a comprehensive overview of the use of additive manufacturing technology. This includes information such as printing times, usage statistics, material consumption, uploaded parts per week, etc.

Additive manufacturing and government initiatives

In May 2022, the Biden administration in the US announced the introduction of the "Forward with Additive Manufacturing" (AM Forward) program.

The primary goal of this program is to leverage modern advances in additive manufacturing technology to strengthen the resilience of the U.S. manufacturing supply chain.

Seven well-known US manufacturers (such as GE Aviation, Raytheon, Siemens Energy, Lockheed Martin, Honeywell, Boeing and Northrop Grumman) have committed to accelerating the integration of additive manufacturing at their small and medium-sized suppliers. To this end, they will increase their use of additively manufactured components while providing technical support, training and implementation assistance.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

![[Podcast: Factory of the Future] Is 3D printing a business case for every factory?](https://www.mark3d.com/de/wp-content/uploads/2023/08/fabrik-der-zukunft-500x383.png)

A clear and concise overview of additive manufacturing! It's impressive to see how versatile 3D printing is being used in the industry. The technology offers truly revolutionary opportunities for manufacturers. Thanks for the explanation!