Toivalan Metalli gains small series production as a new source of income

The company

Toivalan is an established Finnish machine factory whose main customers are machine manufacturers, construction companies, and the mining industry. It possesses the tools and flexibility to meet its customers' needs for customized components. Its services include laser cutting, tube bending, welding, and a range of other offerings. Its customer base includes, among others, construction and elevator companies, weather protection manufacturers, and machine and furniture manufacturers.

The challenge

Partner company Vossi Group developed a practical solution that ensures independence and allows for the exchange of steel tools for process and design validation. A key factor in ensuring survival and success in today's service industry is the ability to keep pace with production facilities and their development.

Toivalan Metalli has consistently invested in advanced manufacturing technologies. In recent years, significant investments have been made in versatile manufacturing technologies such as fiber lasers, disc grinding and edge milling machines, CNC tube bending machines, and tube end forming machines, thus broadening the company's capabilities.

Despite the investments in new, state-of-the-art machinery, one major problem remained unresolved: the ability to handle custom projects in small batches. Because many orders require different tooling and necessitate the purchase of specialized tube bending tools from large suppliers, the cost per part can reach up to €4,000. In addition to the high costs, this slowed down numerous projects due to the associated dependencies and supply chain issues.

Request a DEMO component now!

See for yourself how strong the components are.

“The threshold is minimal. The X7 is easy to operate, and basic training can be completed within a day.”

– Toni Pasanen, Welding Manager, Toivalan Metalli Oy

Examples of Applications

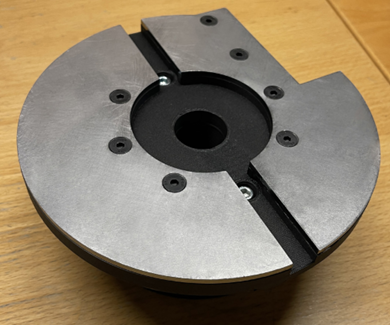

A 3D-printed bending die connected to a metal plate. The long groove is attached to a bending machine, with the sheet metal helping to withstand the torque applied to the tool during bending.

A 3D-printed end cap used as a stop. An internal M6 nut requires a teardrop-shaped hole on the side. For this particular project, the customer only needed a few parts. Manufacturing the entire part from steel would have been six times more expensive.

These precisely bent tubes were produced using the 3D-printed tube bending die.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.