3D printing in education

Niederrhein University of Applied Sciences

Julia Kessler, teaching professor at the Niederrhein University of Applied Sciences, answered a few questions for us in a written interview about how the Mark Two is used at the university, what they have already tested and what added value the Mark Two brings them.

Mark3D: How do you use additive manufacturing at your university?

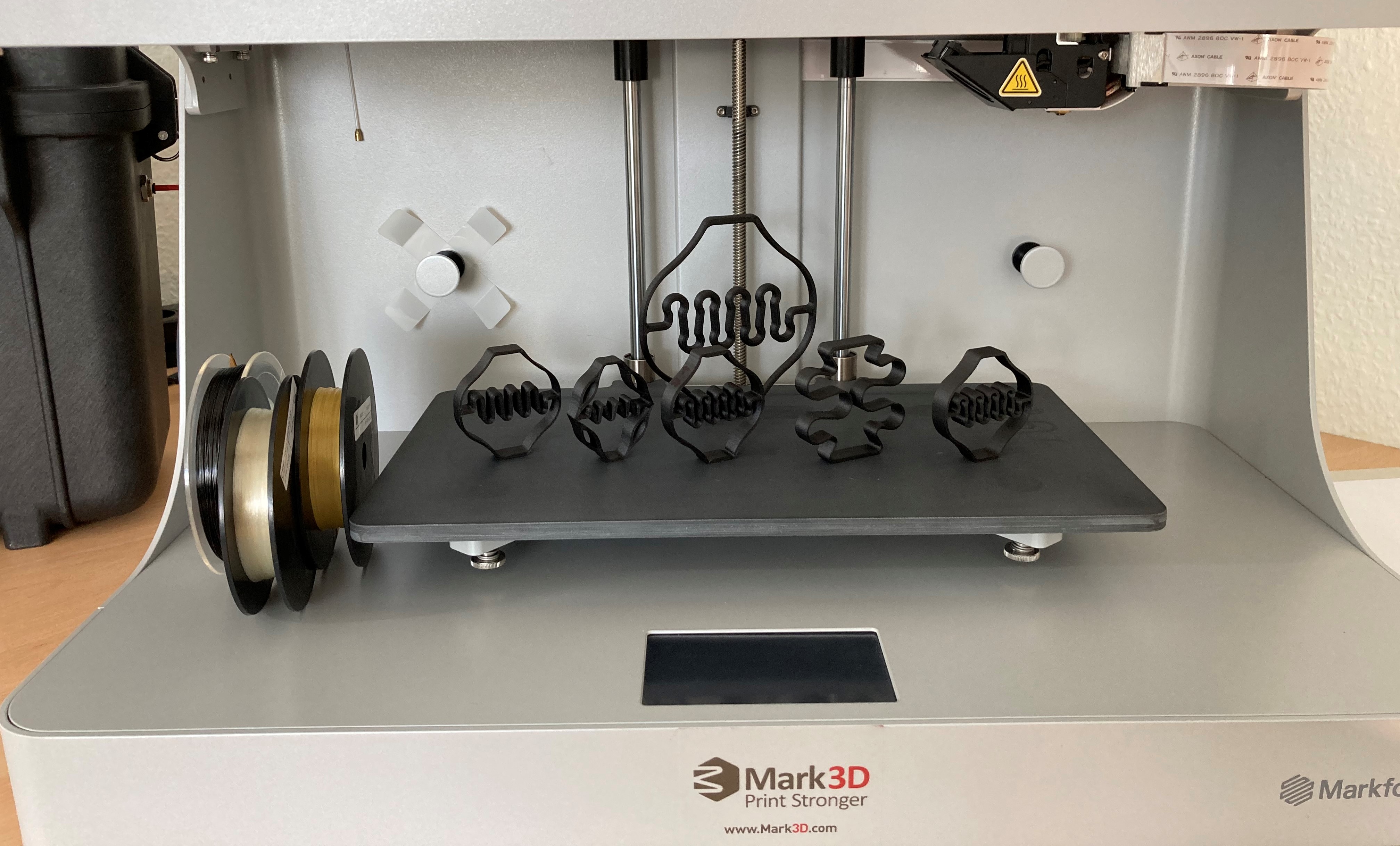

Julia Kessler: The Niederrhein University of Applied Sciences is currently using the Markforged Mark Two 3D printer for student projects and final theses. However, there has already been an industrial application. The current COVID-19 pandemic is naturally also having an impact on universities, causing many practical projects to be limited or even impossible. However, we hope to be able to resume this in the new semester and realize the planned projects and potential research topics with the Mark Two.

Additive manufacturing in education

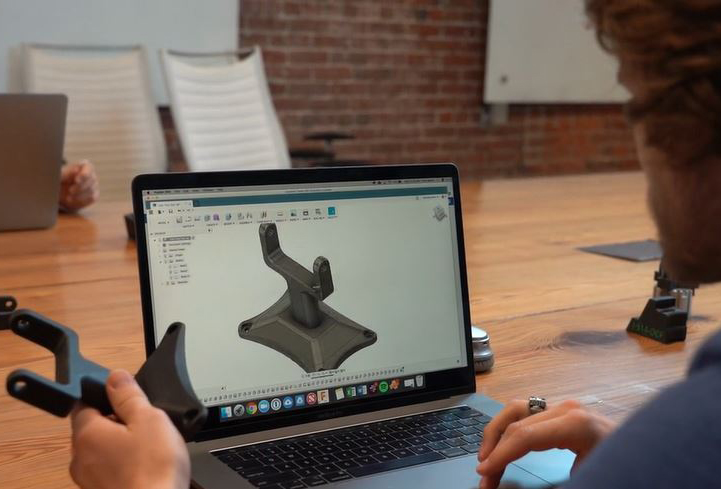

With Markforged's 3D printing solutions, you can optimally prepare your students for professional life. Students find using the 3D printer and the Eiger software very intuitive and enjoyable.

Mark3D: How do you use the Markforged 3D printer? What are your goals? What applications do you print?

Julia Kessler: The Markforged Mark Two 3D printer was acquired for the Niederrhein University of Applied Sciences last year (2020) through an internal research project. The goal is both to familiarize young talent, i.e., students, with this technology and to find ways to transfer it to industrial applications through future-relevant research topics. The fiber-reinforced materials offer a completely new possibility for the implementation of high-strength components.

Mark3D: Why did you choose Markforged 3D printers? How have the parts been manufactured so far? Expectations vs. reality?

Julia Kessler: The Mark Two offers HSN a completely new approach to additive manufacturing and component production, and for me personally, it represents the next important step in developing the additive manufacturing sector. In addition to an existing MakerSpace with various Ultimaker 3D printers, my goal was to strengthen FFF printing through CFF technology and take the next steps toward metal 3D printing. Printing fiber-reinforced materials, such as carbon and glass fiber, makes it possible to engage in high-strength applications and attract industrial partners who previously could not be convinced by pure FFF printing.

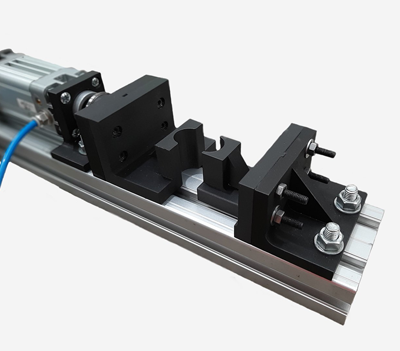

Gear for the study with Jacobs Houben Technologie GmbH

Request a DEMO component now!

See for yourself how strong the components are.

Mark3D: How and where did you hear about Markforged/Mark3D?

Julia Kessler: Since I've been working in the field of additive manufacturing since 2012, I'm naturally familiar with the common additive manufacturing manufacturers and processes. The trade fairs, with the exception of those canceled last year due to the coronavirus pandemic, are always a good place to learn about the latest developments in the technology, both in terms of materials, machines, and applications.

Mark3D: How many departments use the 3D printer?

Julia Kessler: So far, only one department or division (mechanical engineering and process engineering); especially due to the coronavirus pandemic, this is currently not possible.

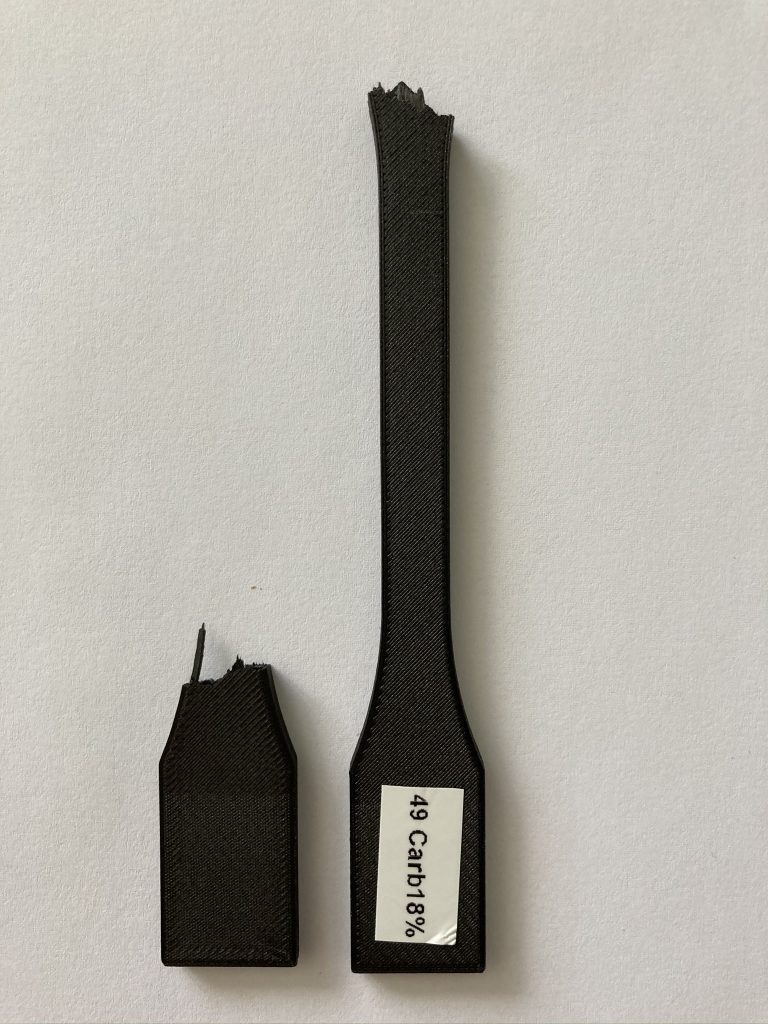

Gear for the study with Jacobs Houben Technologie GmbH, broken at predetermined breaking points for overload protection

Mark3D: What added value have you already achieved through 3D printing with Markforged (research results, evaluations, etc.)? Are there any concrete figures, data, and facts?

Julia Kessler: A bachelor's project focusing on a design guide and the analysis of mechanical properties (tensile tests) has already been successfully completed. A small study was conducted with an industrial partner on the prototype development of a herringbone gear with a predetermined breaking point for overload protection. A paper on "Continuous Filament Fabrication with Continuous Fiber Reinforcement" was also submitted, and a test rig specifically for measuring creep and relaxation behavior for the evaluation of fiber-reinforced spring elements or similar test specimens was developed and constructed. Further tests in the area of hardness measurement are currently being planned, as is the analysis of the specimens for relaxation and creep behavior.

Mark3D: What were the reactions of colleagues, students, and partners?

Julia Kessler: So far, the results have been consistently positive; the tensile test results have been particularly impressive. Students find using the 3D printer and the Eiger software very intuitive and enjoyable. This is particularly important for a university, as it ensures that the theoretical knowledge acquired can also be easily applied in practice. Colleagues are currently beginning to develop initial ideas for interdisciplinary topics and projects (e.g., in the textile sector or the recycling of fiber-reinforced materials) to better integrate the technology into the university in the future.

Tensile test results with 41 % fiber content:

Onyx: 40-42 MPa

Carbon: 346-379 MPa

Kevlar: 270-273 MPa

Glass fiber: 325-331 MPa

HSHT glass fiber: 361-379 MPa

Get to know EIGER now!

The Markforged EIGER software is powerful and very easy to use. Your parts can be quickly optimized with the right settings and fiber orientations to optimally design your part for your application.

Mark3D: What are the next steps? What will be printed in the future?

Julia Kessler: The next steps are to intensively search for exciting applications in the industrial environment, gain new experience in dealing with fiber-reinforced components, launch innovative research projects, and invest in further additive manufacturing technologies. Building on the Markforged Mark Two 3D printer In the future, the Metal X 3D printer fit very well into our university portfolio. Here, too, the Metal X's ease of use, without the need for complicated and safety-critical powder handling, makes it ideal for use in a university setting.

Mark3D: Do you have any other relevant comments about the Markforged machines, software, Mark3D, etc.?

Julia Kessler: FFF technology is sometimes underestimated or ridiculed, but I think the products (at least with regard to our Mark Two and the Eiger software) are impressive. Very positive customer contact and service also make working with Mark3D and its products a pleasure.

Mark3D: Thank you, Julia Kessler, for the informative interview and continued success!

spring element

Learn more about the applications with the desktop series!

How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed some information sources that will help you get the answers you need.

[…] The Niederrhein University of Applied Sciences (HSNR) in North Rhine-Westphalia, for example, was provided by Mark3D with the Mark Two, the 3D printer for […]