3D printed robot grippers in automation – ASS Luippold

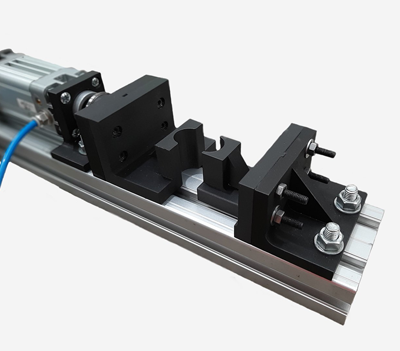

ASS Luippold Automation Systems&Service eK required highly stable and at the same time as light as possible robot grippers for transporting their printed circuit boards.

The grippers printed with Markforged 3D printers meet these requirements.

Even more!

After installation, expectations were even exceeded.

The designers developed a completely new, innovative way of thinking thanks to the new manufacturing freedom.

Further advantages for ASS Luippold:

✅ 6000 hours of successful printing time

✅ 66% Cost savings compared to carbon manufacturing parts

✅ CNC milling department is relieved

✅ faster time-to-market

✅ unmanned production

✅ extreme weight savings

✅ short waiting time for spare parts

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about the applications with the desktop series!

How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed some information sources that will help you get the answers you need.

Hinterlasse einen Kommentar