PTZ Prototypenzentrum GmbH in Dresden has been producing prototypes in metal and plastic for a wide range of industries for over 20 years. PTZ has a great deal of experience with various additive manufacturing processes. No solution was found for particularly demanding applications - until the components could be additively manufactured on the Metal X.

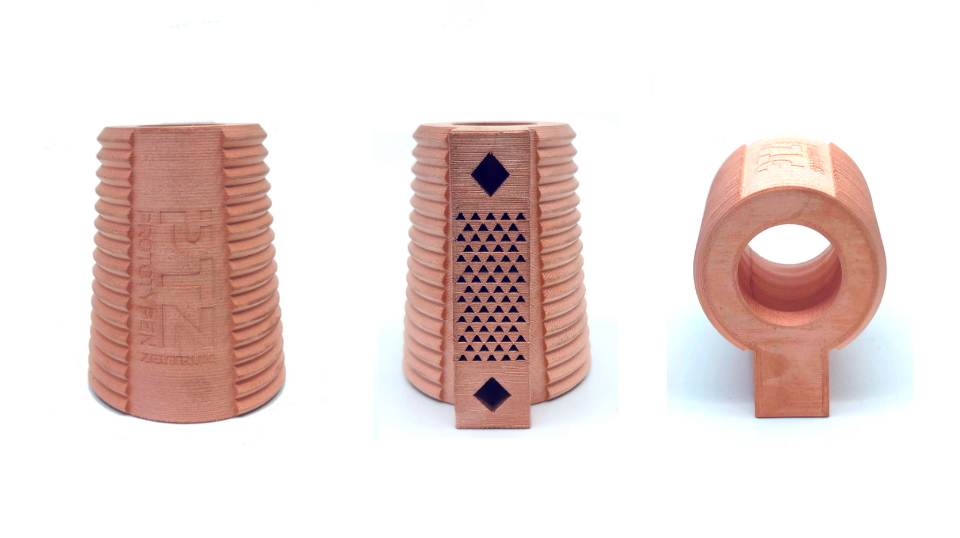

This tool cooler was originally made from machined aluminum. The cooler considerably simplifies the handling of the shrinking process when installing and removing the cutting tool. This is a characteristic component of high-precision milling tools. The more conductive the cooler is, the faster the tool can be reconfigured. The cooler, made of aluminum, was easy to manufacture but could not meet PTZ's desired cycle times due to thermal performance.

Request a DEMO component now!

See for yourself how strong the components are.

Initially, the team tried using selective laser melting technology to produce a more powerful design from an AlSi10Mg alloy. They achieved better performance thanks to the complex internal cooling channels, but the new design could not withstand the cooling medium and the process was quite expensive and difficult to implement.

Markforged's copper was the perfect solution to the PTZ problem. Their new design included conformal cooling channels that would make the mold cooler extremely efficient. However, this design could not be manufactured conventionally. With this design, PTZ was in an excellent position to realize the idea in highly conductive copper on the Metal X.

The new tool cooler can withstand the cooling medium and cools the 38% faster than previous designs. With approximately 40 tool changes per day on two CNC machines, 111 hours per year have also been saved. Given the average hourly rate of the machine, this means that PTZ saves around €7,000 each year in machine time alone. With the most cost-effective and high-performance materials, Markforged technology was the only logical choice for the tool cooler. The team plans to use the Markforged copper to develop electrotechnical parts for the automotive industry.

What are the advantages of copper 3D printing?

✅ Very high conductivities

✅ Quick first prototypes

✅ Significant design freedom

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar