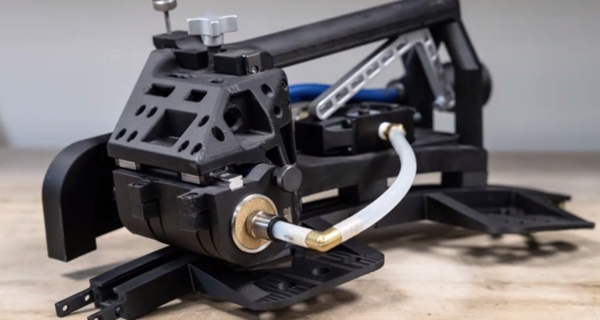

The only way to get industrial-grade parts in your hands in hours instead of weeks, the X7 enables engineers and designers to fundamentally improve their manufacturing operations at lightning speed.

Strength of carbon fiber

The X7 prints parts with endless carbon fiber reinforcement in hours that are as strong as machined aluminum—and can replace it.

Functional parts of all kinds

Whatever your functional requirements—flame-retardant, chemical-resistant, energy-absorbing, high-resolution, or design parts—the X7 has an industrial material or print mode that can produce the right functional part for you.

Industrial reliability and accuracy

Precision-engineered hardware, advanced sensors, and unique software ensure industry-leading accuracy and reliability. Only Markforged industrial 3D printers offer micrometer-level laser scanning for closed-loop calibration, reliably delivering parts with 50 μm repeatability and industry-leading surface finish.

Advanced hardware, electronics and software provide you with an excellent user experience.

Large 3D printing, high-quality resolution

The X-Series' large build volume is ideal for robotics, automotive parts, functional prototypes, and prosthetics, and is nearly three times larger than the Markforged Mark Two build volume. With a layer height of 50 μm, your 3D printed parts will have a beautiful surface, similar to injection molding in both look and feel.

Print with the complete range of Markforged composite base materials and continuous filaments.

The power of continuous carbon fiber at the touch of a button.

3D printing software meets production management

Design your part, upload it to our browser-based software, select from a wide range of composite base filaments and continuous fibers, and click print. It's that simple.

Continuous fiber reinforcement made easy

Success stories

Wärtsilä

Wärtsilä produces the world's first 3D-printed CE-certified lifting tool and can lift a whopping 960 kg (with a safety factor of 4)!

Siemens Energy Innovation Center

Siemens Gas & Energy is printing a customized circular saw housing in Onyx with integrated parts such as a motor and blade to repair gas turbines.

Learn more about the applications of plastic 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged X-Series printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

World-leading companies trust Markforged 3D printers

To contact us, please fill out our secure form.