Vestas optimizes supply chain using industrial 3D printing

The company

When it comes to alternative energy technologies, wind turbines are certainly the most recognizable. With a height of 137–259 m and a rotor diameter of 109–236 m, they dominate their surroundings and are often visible from afar. If you've ever seen a wind turbine, chances are it was manufactured by Vestas.

Vestas began as a small, family-run manufacturer in Denmark after World War II. For many years, the company built and supplied hydraulics for light trucks. In the 1970s, the company began developing alternative energy solutions and completed its first commercial wind turbine in 1979. Since 1989, the company has focused exclusively on wind turbine production, designing, manufacturing, installing, and servicing wind turbines worldwide. Today, Vestas is the world's largest manufacturer of onshore and offshore wind turbines and wind turbine blades. The company is headquartered in Denmark, has several regional offices, and operates more than 15 production facilities worldwide.

The challenge

Wind turbines are huge and expensive machines that must operate reliably and with minimal downtime to be as effective as possible. This means there is no room for error during manufacturing and installation. For this reason, Vestas relies on numerous testing instruments at its production facilities and installation sites. These critical tools were previously procured from various suppliers around the world based on detailed manufacturing instructions. The finished parts were sent to the various Vestas sites, tested for conformity, and—after approval—put into operation. Unfortunately, some of the finished parts supplied by local manufacturers did not fully meet the specifications and failed final inspection. This led to delays in the delivery and installation of the final product.

Even if the parts passed the special inspection process, most were manufactured using time-consuming and costly traditional machining methods and raw materials. Take the top-center (TC) marking tools, for example. These critical tools, which Vestas uses to mark the root end of turbine blades to align pitch, typically took about five weeks to manufacture. To make matters worse, limited machining capabilities meant the Vestas team would have to order multiple versions of the TC marking tool to customize a batch of blades. Or consider the lightning tip receptors, designed to mitigate damage from lightning strikes. These receptors are made from aluminum using subtractive manufacturing and require at least 12 weeks of production time.

Request a DEMO component now!

See for yourself how strong the components are.

“Vestas is democratizing manufacturing by putting it in the hands of our end users while maintaining a centralized model of engineering control.”

– Jeremy Haight, Senior Engineer, Additive Manufacturing and Advanced Concepts, Vestas

At a glance

The solution

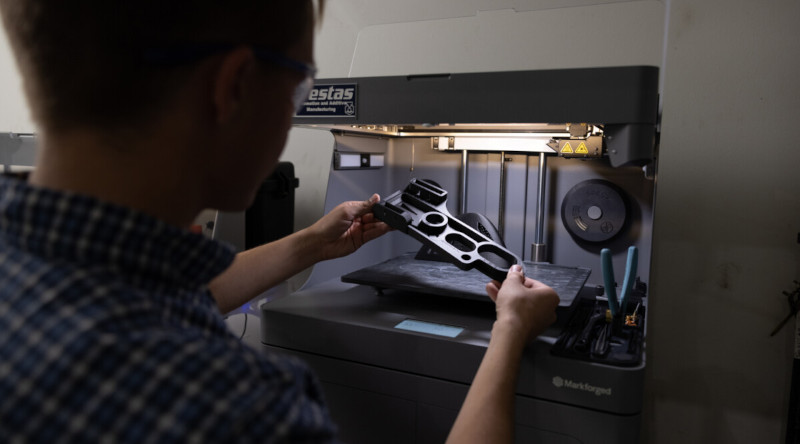

The Vestas team began exploring alternative ways to improve the entire manufacturing process. Using Markforged's cloud-based, AI-powered additive manufacturing platform Digital Forge, the company successfully launched its Direct Digital Manufacturing (DDM) program in 2021. The program makes manufacturing processes independent of external suppliers and provides a knowledge base for collaboration.

The DDM program already includes more than 2,000 Vestas parts stored in a Markforged Eiger™ cloud-based digital repository. This allows employees at any Vestas site—with little to no additive manufacturing knowledge—to quickly search for any number of fiber-reinforced composite parts and print them on their local X7™ and composite parts on their Onyx One™ 3D printers. Jeremy Haight, Principal Engineer for Additive Manufacturing & Advanced Concepts at Vestas, explains: "Our approach is end-to-end. We deliver the physical item to a variety of locations in near real time. I think that's the closest thing to teleportation." Thanks to the repository, the Vestas team knows they'll receive consistent, on-spec parts anywhere in the world instantly, without the need for specialists at global sites. This has drastically reduced shipping and freight costs, as well as manufacturing lead times.

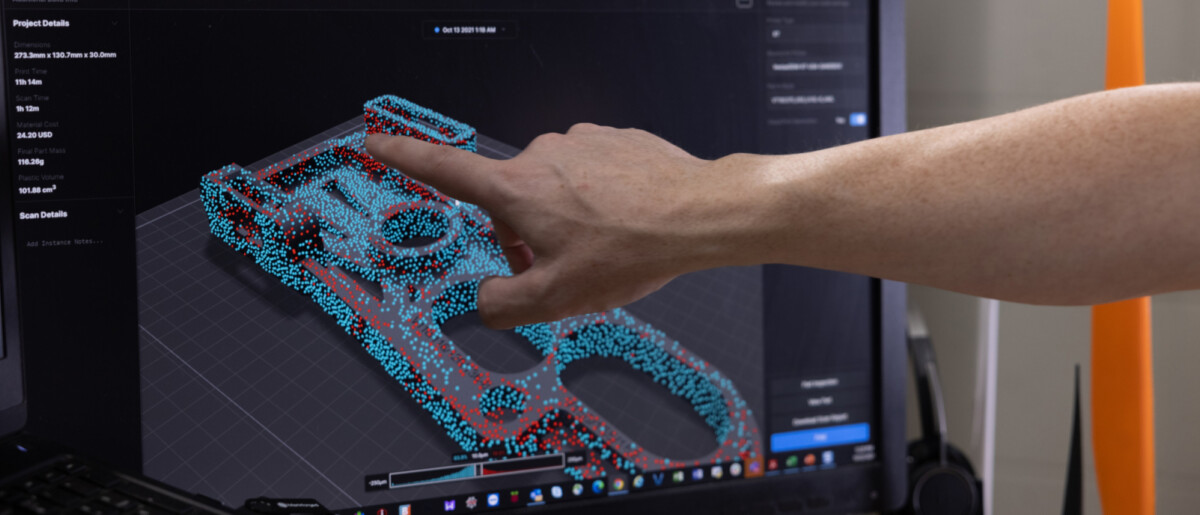

A few examples of how DDM works are the previously mentioned TC marking tools and lightning spike receptors. The TC marking tool, which previously took weeks and thousands of dollars to manufacture, is now produced in just a few days. And because the tool is printed from fiber-reinforced Onyx, a durable, lightweight nylon blend, the formerly metallic parts now weigh 85 lb less than before. As for the lightning spike receptors, local blade fabrication facilities can produce them from 3D-printed copper as needed. Vestas estimates that each of these receptors will take about two days to manufacture once implemented. Most importantly, the Vestas team no longer has to worry about these or other parts failing compliance tests because they are printed on demand and in-house to exacting digital specifications. Furthermore, the tools' accuracy is verified using Markforged Blacksmith™ for in-process inspection, analysis, and reporting.

"We chose Markforged because they were best positioned to deliver the end-to-end solution we needed to realize our DDM vision."

– Jeremy Haight, Senior Engineer, Additive Manufacturing and Advanced Concepts, Vestas

The future

Vestas views DDM as critical for new product development and the availability of tools and end-use parts across the company. In 2022, the company will begin rolling out DDM for the manufacturing of inspection gauges beyond rotor blades, facilitating on-demand gauge production at all 23 manufacturing sites. Vestas has also partnered with Würth to build an additive ecosystem and manage an inventory of spare parts manufactured with the Digital Forge platform to support maintenance, repair, and operations (MRO) for local field service and other suppliers.

Once the initial rollout is complete, Vestas will turn its attention to implementing a more comprehensive end-to-end process across its sites. The company is making it easier for authorized individuals at any Vestas site to scan a part code or search for a part in its Enterprise Asset Management (EAM) and Enterprise Resource Planning (ERP) systems and automatically send it to the correct local 3D printer. This centralized control of operators, printers, and part inspection with Blacksmith and Eiger Fleet™ ensures high-quality, high-performance tools and end-use parts that perform the tasks for which they were designed. The more Vestas brings manufacturing in-house using additive manufacturing, the faster its products will get to market, and the more time and money the company will save in the process.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.