The company

Boehringer Ingelheim Pharma GmbH & Co. KG is a globally operating pharmaceutical company with approximately 52,000 employees.

The Biberach site, with over 6,500 employees, focuses on research and development as well as the biopharmaceutical drug manufacturing. Boehringer Ingelheim utilizes additive manufacturing in a wide range of mechanical engineering applications, from metal construction to robotics.

Request a DEMO component now!

See for yourself how strong the components are.

Project goals

Competitive Advantage Through Additive Manufacturing

Hubert Reiter, Head of Mechanical Engineering at Boehringer Ingelheim, has already had the opportunity to learn about all the new processes. "3D design combined with 3D printing is really cool."

In addition to ensuring the smooth operation of the site, the Mechanical Engineering department focuses on developing custom technical solutions within the company network that are not available on the market in the desired form. Additive manufacturing is a key aspect of mechanical manufacturing at Boehringer Ingelheim Pharma.

"Currently, the most interesting work is for research, as we purchase laboratory robots and modify them to meet our specific requirements. This gives the company a tremendous competitive advantage, especially when using additive manufacturing!"

Approach

Advantages of Additive Manufacturing

Even bionic shapes, which were practically impossible to produce using conventional manufacturing methods, can be easily printed.

Compared to conventional manufacturing methods, 3D printing is extremely cost-effective. The investment in operating costs is low, and the space requirement is very small. The printers run unmanned around the clock!

"Even for a small CNC machine, which you can't get for less than €100,000, you still need tools and a trained specialist – all of that is eliminated with 3D printing technology. Here, the designer operates the 3D printers."

Printing can start immediately after the drawing is created. The time required to create manufacturing drawings is no longer necessary.

What characterizes a good 3D printing system?

“The 3D printer must be ready to use immediately! It's not the user's job to figure out the optimal temperature, feed rates, etc. Printer and filament should come from the same supplier and be compatible. The filament should be of consistent quality. The 3D printer should also be sturdily built: the feeds, axes, and extruder must operate smoothly, and the temperature control must be accurate. Furthermore, it's very advantageous if the build platform is removable so that the workpieces can be safely removed. Last but not least, the parts should look good – after all, it's high-tech manufacturing,” says Hubert Reiter.

“I can’t imagine how we ever managed without Markforged 3D printers!”

– Hubert Reiter, Head of Mechanical Engineering

Solution

Some examples from everyday pharmaceutical practice

“The first two Markforged 3D printers worked flawlessly, so there was no reason for us to switch to another manufacturer. All four 3D printers run around the clock and are operating at very high capacity,” says Hubert Reiter with satisfaction.

Previously, several steps were necessary to produce the finished component, which lengthened the entire process: design, material selection, checking stock levels, ordering materials, creating shop drawings, scheduling production, and processing raw materials – resulting in a manufacturing time of 6-8 weeks.

Now the printer runs through the night, the components are finished in two days, and Boehringer Ingelheim is independent of internal or external resources.

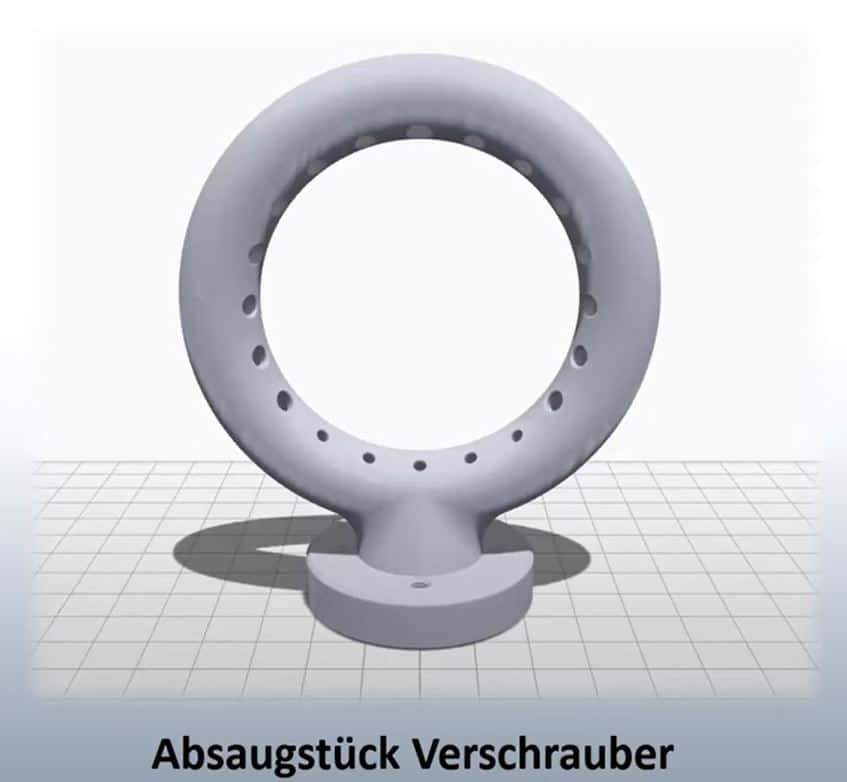

Boehringer Ingelheim 3D-printed a point extraction system for a laboratory robot, without support structures and almost hollow due to the internal drilling. "That was a challenge, but it's worth pushing the boundaries of technology!"

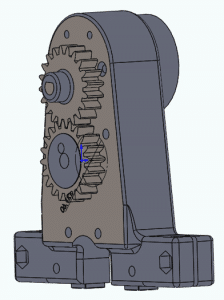

The image in the upper left shows a handling device used in a laboratory robot for milling tissue samples. The cylindrical stainless steel component is a mill developed by Boehringer Ingelheim. During the development process, the device was operated manually and later augmented with a gearbox. Automation through the motor-driven gearbox enables a fully automated process, allowing the laboratory to process more samples in less time. All black components of the handling device, including the gears in the gearbox, are 3D printed!

A product feeder for a packaging system was previously manufactured from several components. Now it can be printed as a single, complete part. "A feeder has to function flawlessly; nothing can get stuck."

"We bond larger parts together with an industrial-grade superglue and a tenon joint. This allows us to work very efficiently within the available build space."

Further advantages of FFF 3D printing for Boehringer Ingelheim Pharma:

+ low acquisition costs

+ low manufacturing costs

+ extremely easy operation

+ very stable process

+ high precision

+ minimal post-processing

+ ability to produce very robust components

The future

New machines are constantly being added.

FFF 3D printing is the simplest and most cost-effective process with the widest range of applications. Even metal 3D printing using the FFF process is currently establishing itself as another standard technology and represents an interesting alternative to the SLS process.

3D printing has already established itself as a standard technology in mechanical manufacturing. Additive manufacturing is not a future technology, but a present-day technology!

At a glance

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.