The workshop for people with disabilities run by Lebenshilfe Leer is a recognized institution. It offers people with disabilities the opportunity to develop, increase, or regain their abilities and provides a wide range of jobs.

Additive manufacturing offers a particularly valuable benefit here.

Industrial 3D printing at Lebenshilfe Leer

It's a mild but sunny afternoon in the spring of 2022. I'm on my way to visit Arnold Koens at Lebenshilfe Leer.

The facility's buildings are located directly behind the Ems River dike. As I park, a new cruise ship from the Papenburg shipyard is being transferred on the Ems in the background.

Arnold Koens' applications are said to be no less impressive, which is why I made the trip to northern Germany.

Years of Experience in Fixture and jigs

Arnold Koens, a fixture builder with a passion for his craft, has been manufacturing custom fixtures for around four decades. Initially a special-purpose machine builder, he developed individual components early on. All his expertise now flows into the fixture construction department of Lebenshilfe Leer.

The work and employment opportunities for people with disabilities at the Lebenshilfe Leer workshop are very diverse.

As a partner to industry and commerce, a wide range of production and services is offered.

Custom fixtures are constantly needed for these production processes.

Initially, the fixtures were manufactured using conventional methods. However, a high degree of product variety and short-notice design changes led to bottlenecks. "A visit to another Lebenshilfe organization made me aware of the possibilities of additive manufacturing," Arnold Koens tells me.

At a glance

Greater Flexibility with Improved Ergonomics

Arnold Koens wanted more flexibility and availability in the production of custom-made fixtures.

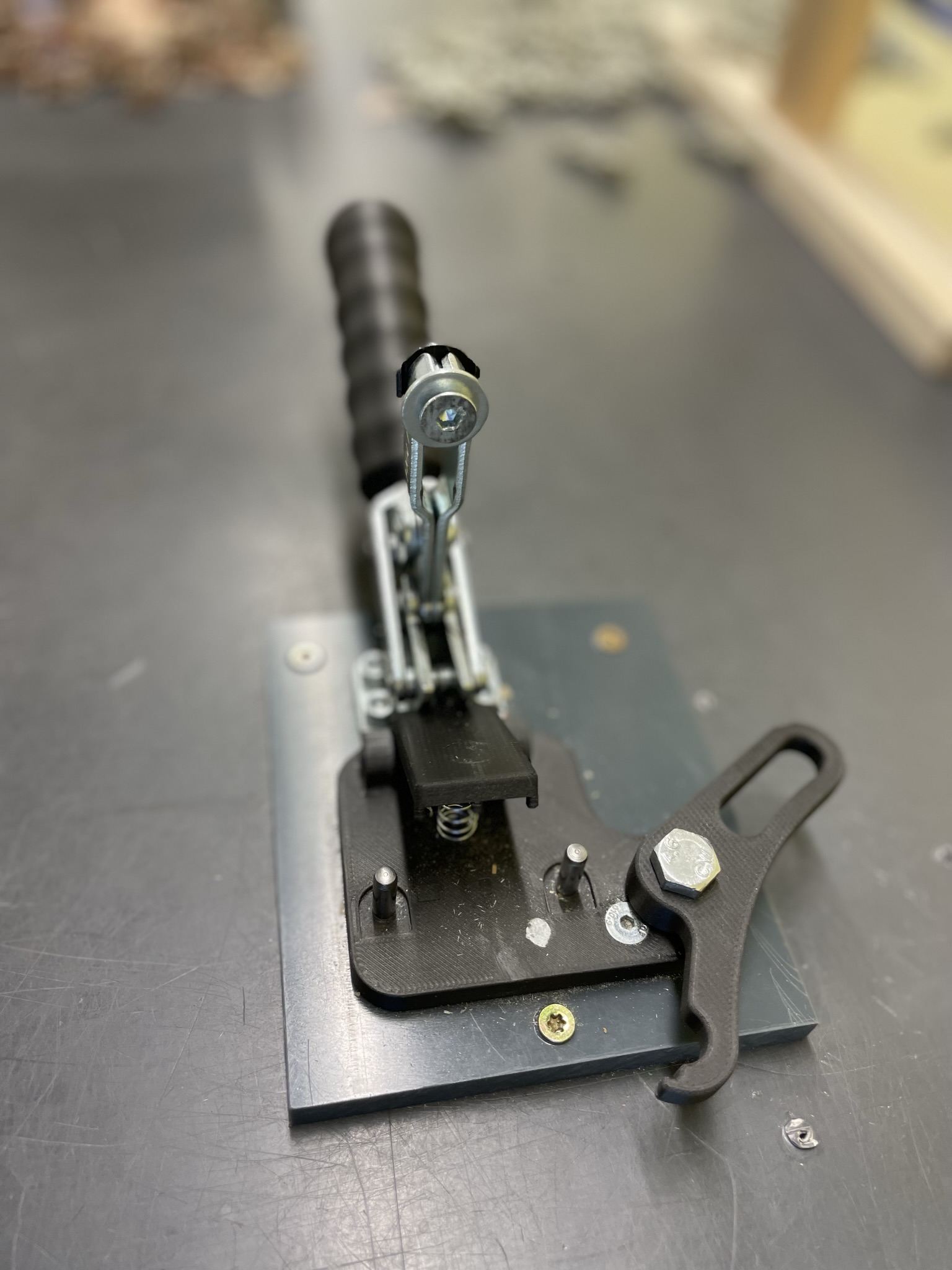

It's difficult not only for people with disabilities to hold a workpiece and work on it simultaneously. The 3D-printed fixtures are designed so that the workpieces cannot slip. He utilizes, among other things, the Poka-Yoke principle.

In the design process, Arnold Koens directly considers the users' needs. For example, the handles are optimized or curves are incorporated to improve ergonomics.

"We want to make working here as pleasant and efficient as possible," explains the fixture maker.

Wir laufen vom Hauptgebäude in eine weitere Halle in der Werkstücke für einen Automobilzulieferer produziert werden.

The Lebenshilfe Leer site extends over several blocks and is currently expanding.

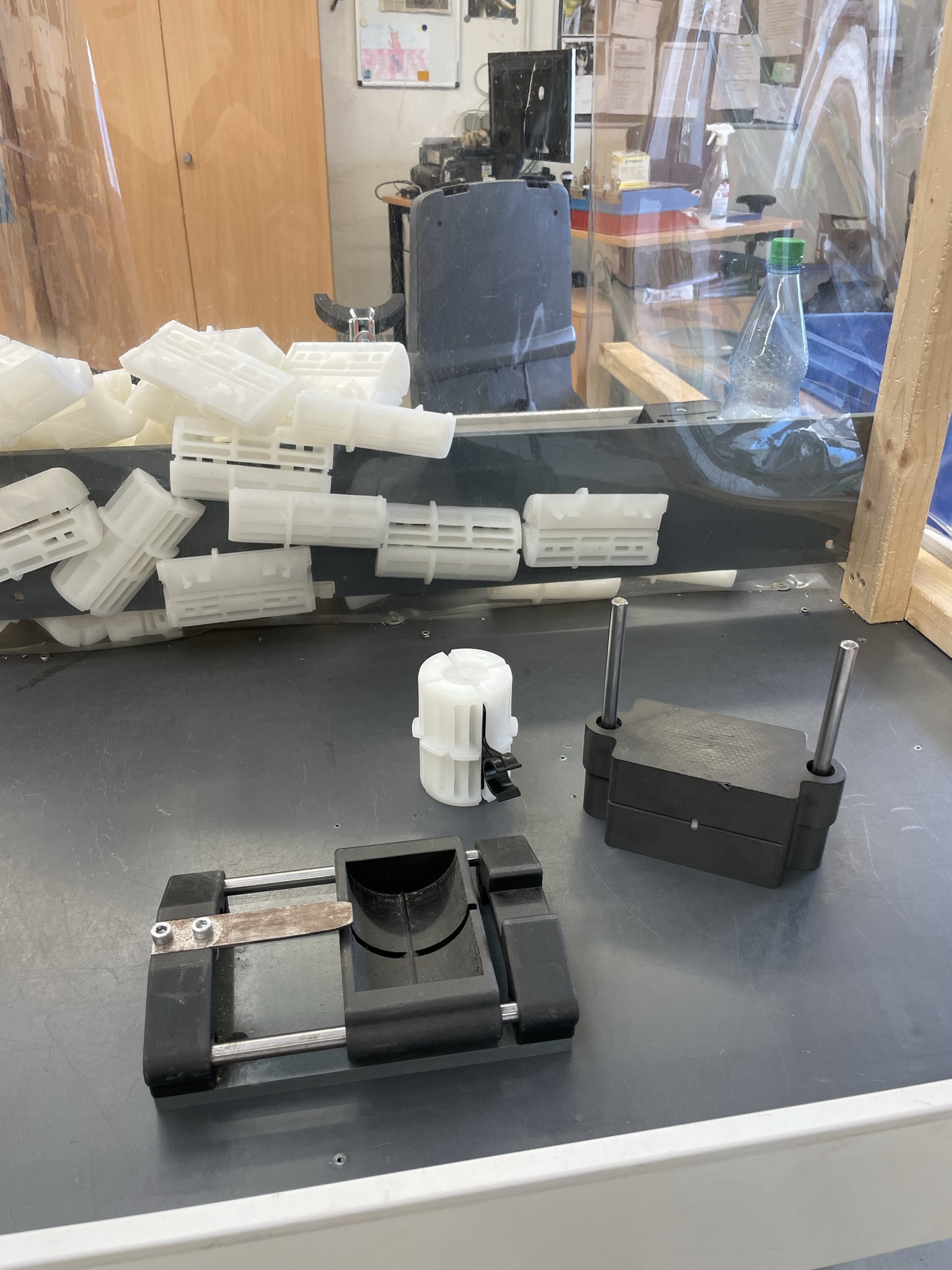

Arnold Koens shows me many of his printed components. His experience and attention to detail are evident in each one.

Arnold Koens “With the smallest adjustments in the design, a lot of material can be saved,” he explains to me.

The industrial partners usually supply the equipment and tools needed to process an order.

"However, these are often very expensive, as well as large and unwieldy. In addition, we only get a few of these fixtures. This means that only a small number of personnel can work on a single order. I can design my own fixtures much more effectively. The number doesn't matter either." The costs are also borne by the clients.

Plug-and-Play Industrial 3D Printing

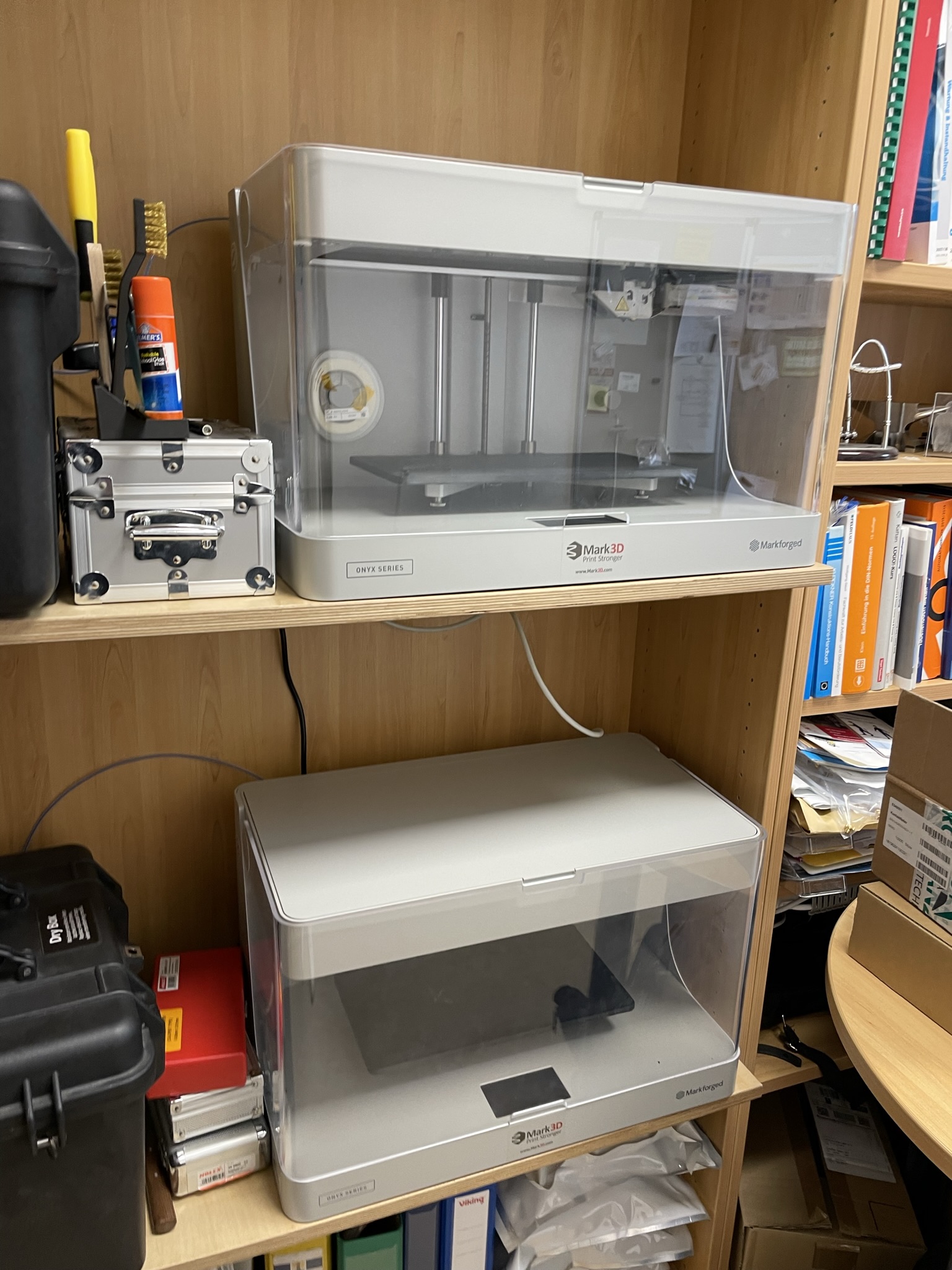

Two Markforged 3D printers are located right in Arnold Koens' office, and the printed fixtures meet all requirements. The components from the Markforged machines also look fantastic. You can hardly tell they were printed. Onyx is a PA6 with short carbon fibers. If needed, the fixtures can also be reinforced with continuous carbon, Kevlar, or glass fiber. "We hardly experience any wear and tear, and practically nothing ever breaks down here," Arnold explains.

The Eiger software is also ideal for him. "I really need to concentrate on designing the fixtures and tools and don't want to mess around with printer settings and parameters."

"If you need something quickly, it's printed in no time! The 3D printers run over the weekend and the parts are ready to use on Monday! We now have much greater flexibility and availability."

– Arnold Koens, Fixture Maker, Lebenshilfe Leer

Request a DEMO component now!

See for yourself how strong the components are.

Additive manufacturing is being further expanded.

At Lebenshilfe Leer, Arnold Koens impressively demonstrates the importance of customized devices. In addition to the obvious savings in costs, time, and storage space, these devices enable many people with disabilities to work more comfortably.

In the future, additive manufacturing will also be used for industrial orders. This will allow the printers to be utilized even more efficiently. I am impressed by the work that Arnold Koens and Lebenshilfe Leer are doing here. With many new impressions, I'm heading back to Haiger.

Written by David Schlawer

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.