Markforged's composite 3D printers make it easy to produce strong parts where and when they're needed, without the long development cycles or high costs associated with conventional, one-off manufacturing.

The ability to modify a design to make it lighter while maintaining metal-like strength through fiber reinforcement also opens up the possibility of adapting a design accordingly and expanding its functionality. Other features such as vacuum systems, sensor mounts, and cable guides can be incorporated into the design of the additively manufactured end effector. Integrating these elements also minimizes the risk of entanglement or collision with other parts of the work environment, ultimately reducing potential downtime. Lighter parts are also compatible with smaller robots, allowing manufacturing teams to deploy an automation module with a collaborative robot at any position in the production line.

Digital Forge™ enables teams to keep the production line running and produce the parts they need right on the shop floor. • Design custom parts to solve production challenges.

- Design custom parts to solve challenges on the production floor.

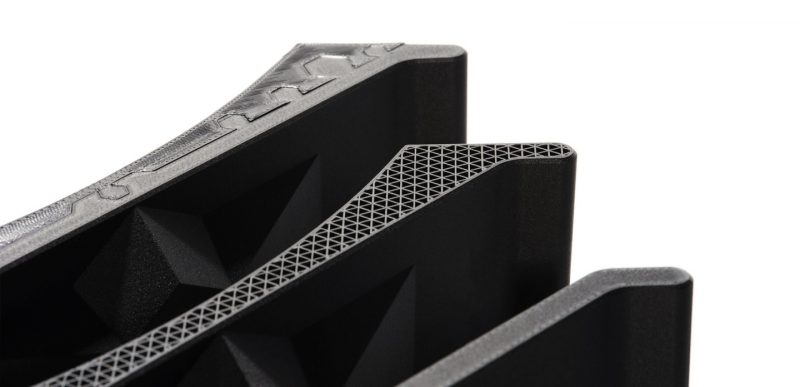

- Create complex geometries with industrial-grade materials like Onyx®, a microcarbon fiber-filled nylon.

- Use continuous fiber reinforcement (CFR) to create lightweight composite parts with the strength of metal.

- If necessary, access an already approved EOAT part from the digital inventory of additive manufacturing.

Development process

A suction gripper for a production line, used in the final packaging step to transfer individual containers into retail packaging units. Since the distance between the grippers depends on the specific product and container shape, an additive manufacturing EOAT allows the manufacturing team to quickly adjust the length to meet current requirements without adding weight. Manufacturing the parts in-house avoids delays in the delivery of a custom part from a supplier. Producing the parts with Onyx accelerates their availability, lowers the overall cost, and reduces the weight (and therefore the strain) on the packaging robot.

The main advantages

- 1. Produce in hours instead of weeks, as is the case with traditional custom part production.

- 2. Expand your digital portfolio of solutions to further accelerate transitions.

“The logistical complexity of a rapidly growing number of new items and demand-driven production can be managed directly on the production floor.”

–

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar