Industrial 3D printing in practice.

User reports and practical examples

the Markforged 3D printer

the Markforged 3D printer

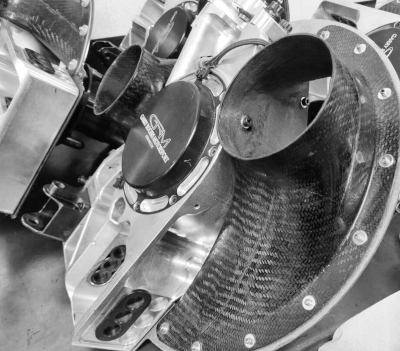

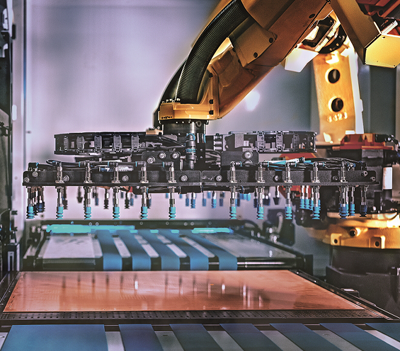

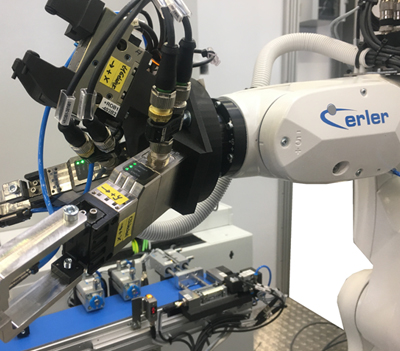

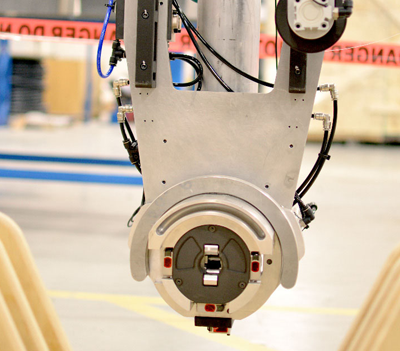

In the Automotive industry, Aerospace, Automation & Robotics, electronics and in many other industries, leading companies around the world are already using Markforged technology to explore innovations faster and at lower costs.

Industrial 3D printing in practice.

User reports and practical examples

the Markforged 3D printer

the Markforged 3D printer

In the Automotive industry, Aerospace, Automation & Robotics, electronics and in many other industries, leading companies around the world are already using Markforged technology to explore innovations faster and at lower costs.

Sports photography

When Jan Brüggemann needs a custom mount for his sports photography, he designs and prints it himself!

Manufacturing redefined

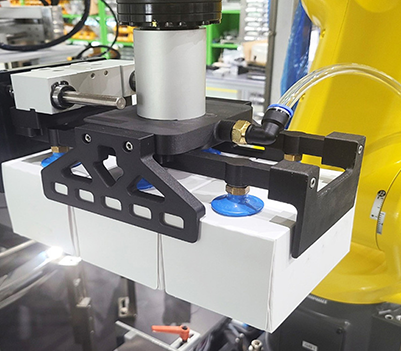

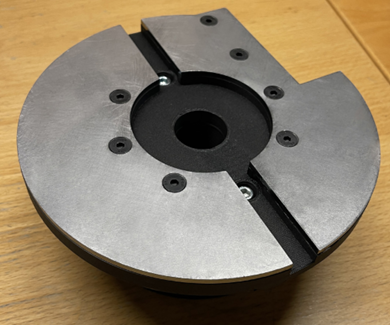

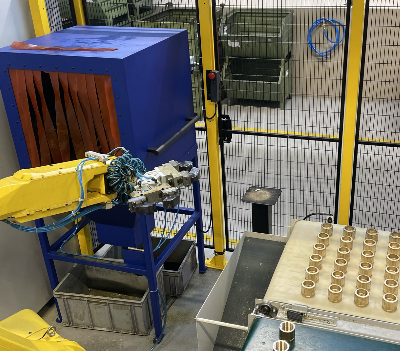

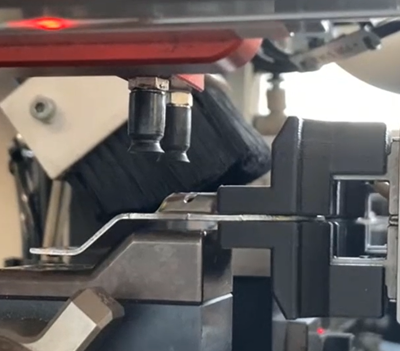

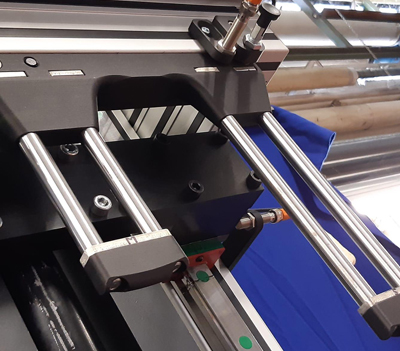

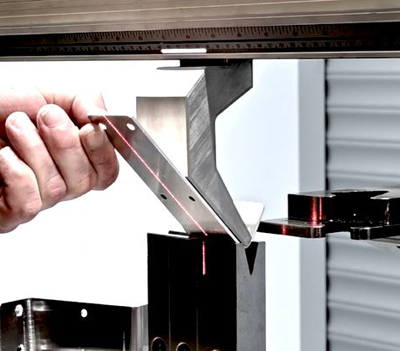

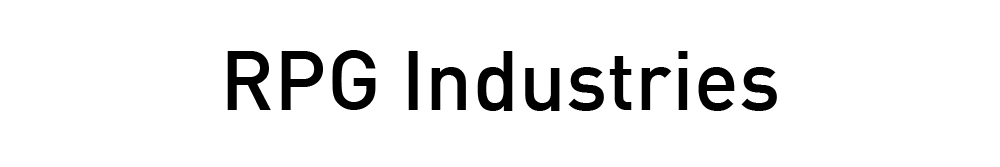

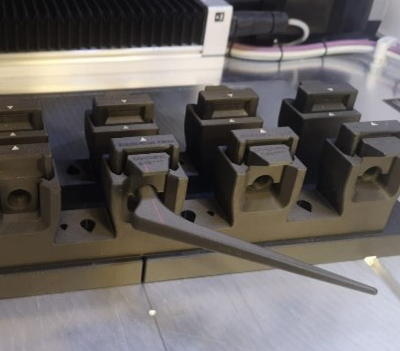

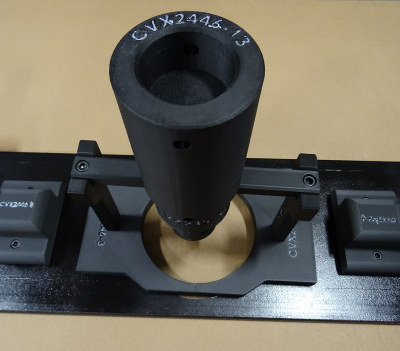

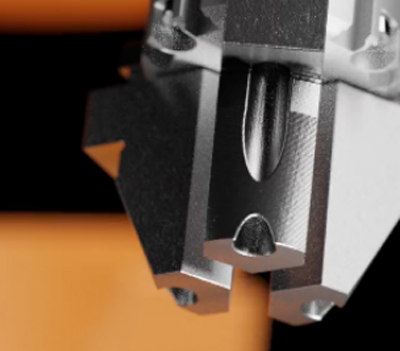

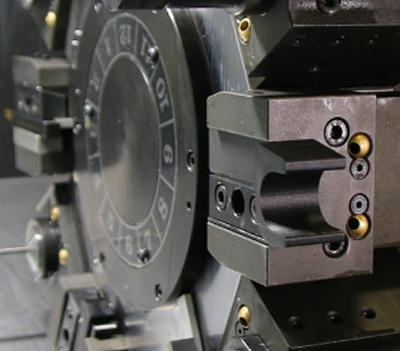

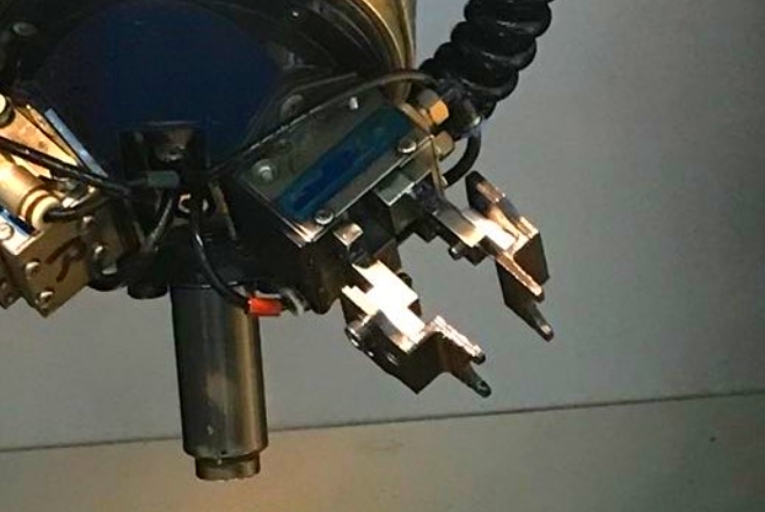

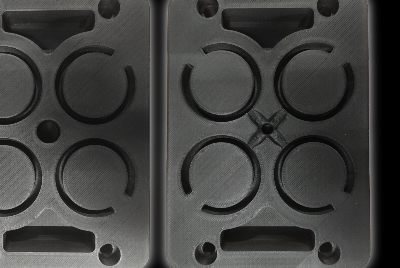

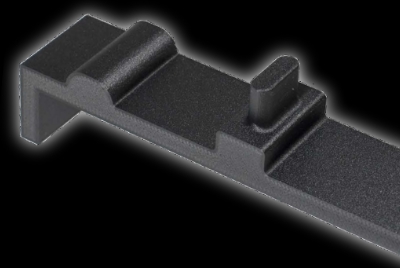

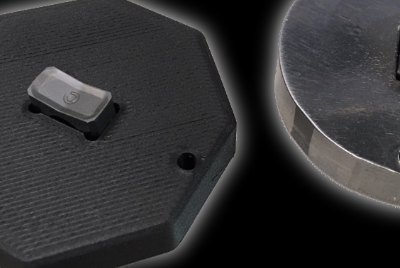

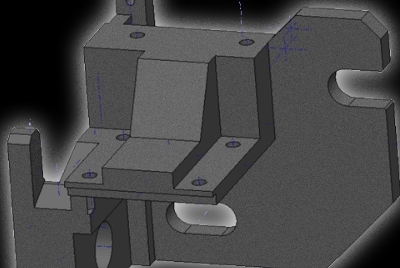

Additive manufacturing is not only useful as a production method for end-use parts, but also as a complement to other production processes in mechanical manufacturing. Industrial 3D printers produce high-strength parts that are robust enough to withstand the manufacturing environment where printed parts are used as tools and fixtures. The applications on this page demonstrate how Markforged users have reduced costs and optimized production availability in their everyday production operations.

From custom soft jaws for difficult machining to alignment fixtures for welding, an industrial 3D printer can improve many of the behind-the-scenes tasks associated with manufacturing and production. Complement your manufacturing with a Markforged 3D printer and experience shorter lead times, increased machine bandwidth, and lower manufacturing costs.

We're working with Markforged on a mission to unlock the next innovation in design and manufacturing. We've developed an industrial 3D printing platform to free designers and engineers from decades-old, slow processes. Volkswagen, Google, Siemens, Amazon, General Electric, and thousands of companies across 50 countries use Markforged to print same-day prototypes and produce stronger end-use parts than ever before. With Markforged, you can ship 50x faster, spend 20x less, and build 23x stronger products.

READY TO GET STARTED?

Learn more about the return on investment of a 3D printer in your company:

Practical applications of Markforged 3D printers

If you'd like a demo, have questions, or need a quote, please leave us a message here:

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

World-leading companies use Markforged 3D printers

To contact us, please fill out our secure form.