Manufacture the component correctly every time!

Inspection for the X7 takes the quality control process to a whole new level. The X7 is the only industrial FFF 3D printer that inspects parts during production using scanning.

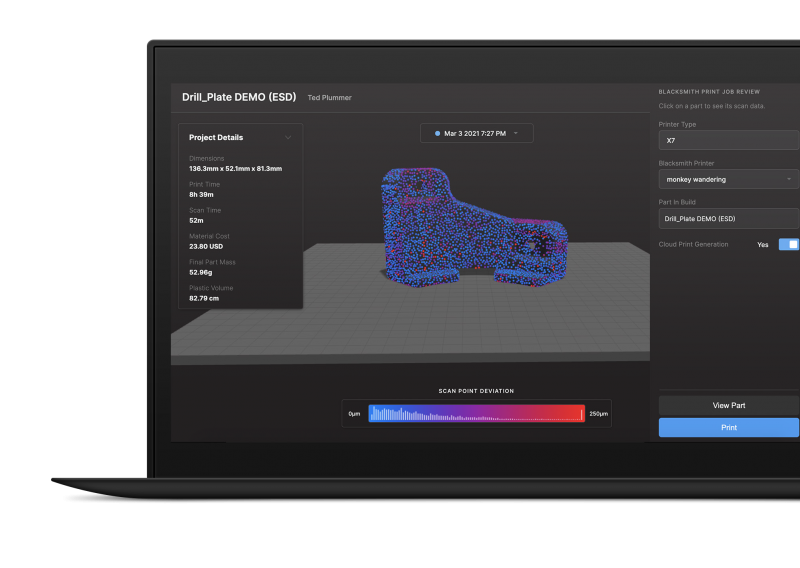

Inspection is a paid license for EIGER, Markforged's additive manufacturing software. Inspection calibrates, scans, measures, and compares the dimensions of printed parts with the dimensions of your design files—so you get even more precise parts directly from the 3D printer.

The advantages of Inspection:

Calibrate machine

The automated calibration processes ensure that every 3D printer operates with the same quality standards required for inspection.

Print and scan part

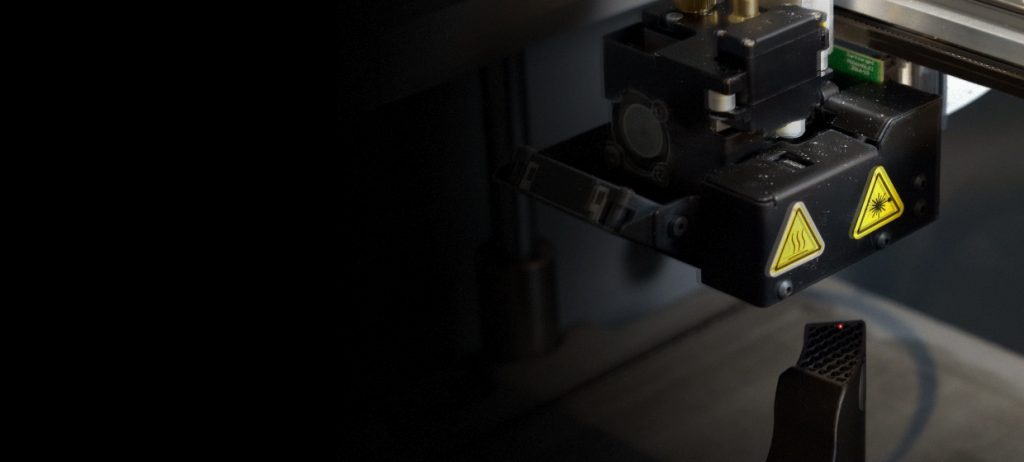

Inspection uses the integrated laser and a patented, intelligent scanning process to reliably measure parts during printing.

Compare scan data with STL

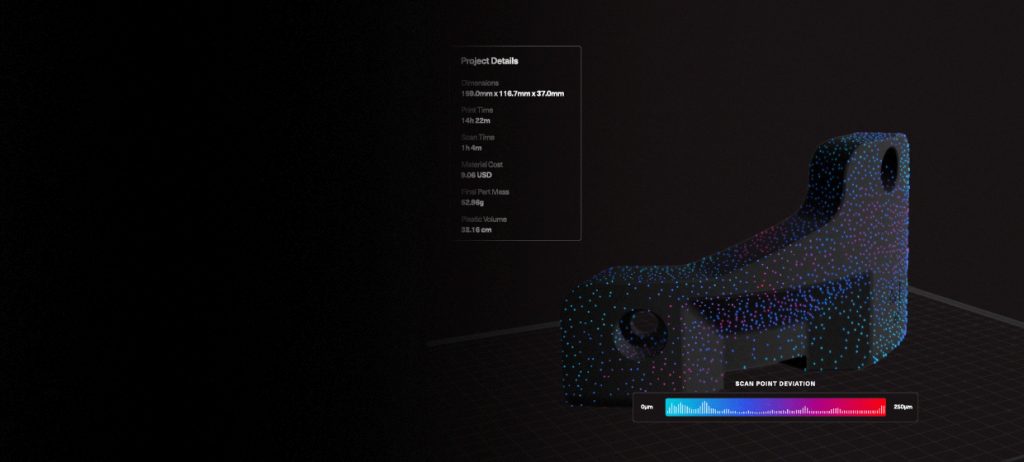

Inspection saves the measurement data during printing and compiles it in EIGER for review. The data is automatically recognized and compared with the STL file.

Data Report

View deviations in the part's geometry and set tolerance limits to assess part quality. The print report is saved in EIGER and can be accessed at any time.

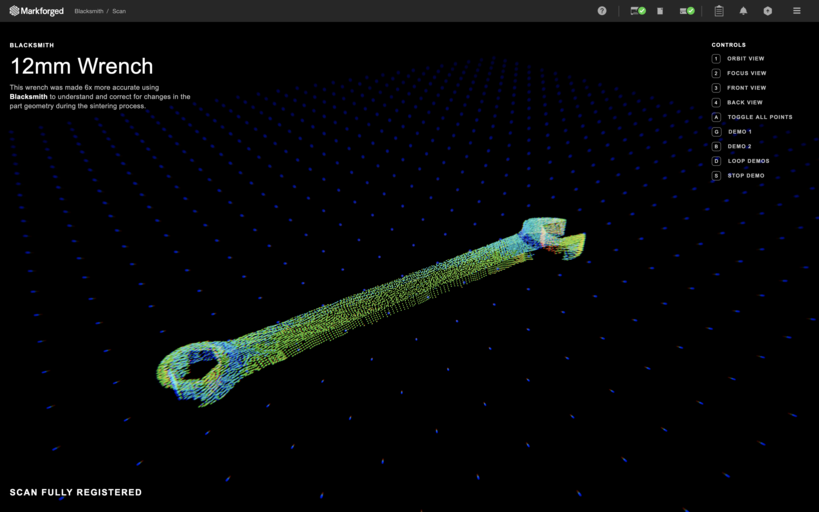

Close the loop with adaptive manufacturing

Inspection creates a continuous feedback loop to make parts more accurate. The software analyzes a design, compares it to the scanned part, and automatically adjusts the end-to-end process to produce parts that meet specifications. Inspection continuously learns and adapts to process variations throughout the lifetime of your machine.

Growing competence with increasing global production

Markforged's AI solution gets smarter with every part, meaning it learns as global production increases. Inspection makes the world's factories more efficient, accelerates time to market, and reduces production costs.

Learn more about the applications of continuous fiber plastic printing!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions, or need a quote for a Markforged 3D printer and inspection software?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.