We're excited to introduce the newest material for the Metal X System—copper. For the first time, it's now incredibly easy to 3D print pure copper. With the Markforged Metal X system, you can now easily create complex parts with high electrical and thermal conductivity that were previously expensive, time-consuming, or even impossible to manufacture. Copper joins the existing Metal X materials—17-4PH stainless steel, Inconel 625, H13 tool steel, D2 tool steel, and A2 tool steel.

What is Markforged Copper?

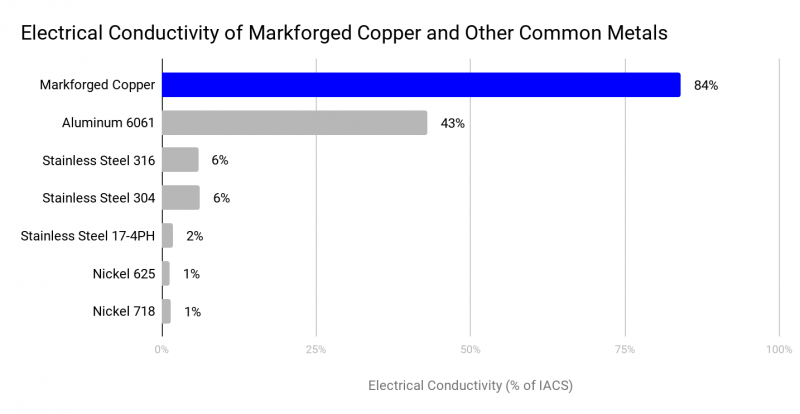

Markforged copper consists of more than 99.8% pure copper with excellent thermal and electrical conductivity and high ductility. Markforged copper can be used wherever thermal or electrical conductivity is required—and conventional manufacturing processes are too expensive or inadequate. Alternatively, customers who work with aluminum over copper due to processing challenges can now easily 3D print a copper part and benefit from the material's higher thermal and electrical conductivity.

Source: https://www.upmet.com/

Copper is a metal material known for its thermal and electrical properties. This is extremely exciting for us. In our Data sheet You will receive a detailed overview of the electrical, thermal and mechanical properties.

Copper and the Markforged Metal X system

Copper components are removed from the Markforged Sinter-2 after the sintering process.

There are several reasons why we are excited about copper:

Printing with Markforged copper follows the same simple process that Markforged customers are used to with our existing metal materials on the Metal X system. No hardware changes are required to start printing with copper. Markforged customers order a spool, select "Copper" from the material dropdown menu in our Eiger software, and begin printing immediately. Switching materials on the Metal X takes approximately 10 minutes. With Markforged Copper, we are excited to offer customers the ability to produce electrical and thermal components on the same printer as our stainless steel, nickel superalloy, and tool steels. We are working on additional materials in our labs to further expand the range.

The Metal X utilizes a Fused Filament Fabrication (FFF) processing method, simplifying copper printing for the first time. The process begins with metal powder encased in a plastic binder (which allows for the safe handling of filament on a spool), which is then fabricated layer by layer into the final part shape. After printing, the part is washed to de-bond the wax content, then the part is baked in a sintering furnace. This allows the remaining binder to be thermally removed, and the powder can then be sintered into the final solid metal part. This process overcomes the traditional challenges of 3D printing copper with directed energy systems (such as DMLS) due to copper's high thermal conductivity.

Markforged copper offers Metal X customers the ability to print parts requiring thermal and electrical conductivity, opening up a range of new applications for manufacturers across multiple industries.

A 3D printed copper welding arm

Applications

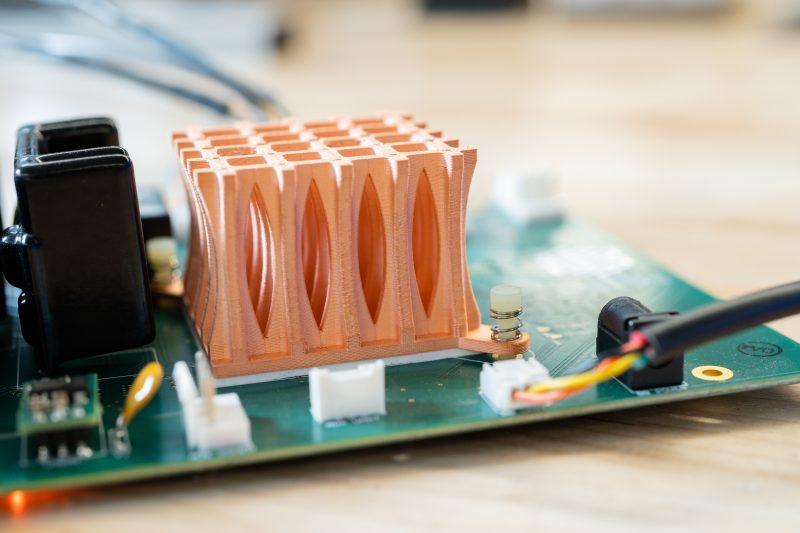

From welding arms and heat sinks to other electrical connections, Markforged customers can now reinvent the way they manufacture copper components. Customers are even experimenting with printed parts with complex internal cooling channels. Eliminate soldered or welded assemblies to reduce costs, increase consistency, and eliminate weak points.

Here are some more ways you can use Markforged:

- Parts with low quantities. Print in copper for low-volume parts when tooling costs would be too high and geometries would be complex. Examples include busbars and heat sinks.

- Tools. Users have already seen great results printing tools in copper. A good example would be spot welding arms, which require high electrical conductivity.

- Functional prototypes. Users can test ideas in copper before investing in production tools.

Conclusion

Copper is now available to Markforged customers worldwide. We're excited to see what our customers print with Markforged Copper. This is manufacturing redefined—what are you waiting for?

Request a DEMO component now!

See for yourself how strong the components are.

Leave A Comment