This begins a series of articles about our new 3D printer Mark X (Revised in 2021: the new name of the Mark X is X7.) This post focuses on the new production monitoring feature. This is the first step toward closing the production loop for 3D printed parts.

Why the loop must be closed

Ideally, there would be no difference between the design of a part and the actual finished product. Assemblies would fit together effortlessly, and even complex geometries would look as perfect and beautiful as they do in the CAD program. Unfortunately, this is unrealistic. Due to imperfections in manufacturing, deviations arise that must be tolerated. Tolerances serve a simple purpose: to explicitly define how incorrect a part can be while still remaining usable. By setting reasonable targets here, designers can reduce costs for parts that require less precision, or produce incredibly precise parts for the most effective functions.

Due to very small tolerances in 3D printing, the bearing fits into the turbine housing.

For designers, tolerance specifications are an effective tool. They close the manufacturing loop. For processors, they're more of a necessary evil. After the manufacturing process is complete, each part must be carefully inspected. If the deviation is too large, the entire part is disqualified and must be remanufactured before it can be inspected again. This is where the loop opens. This is particularly problematic with 3D-printed parts. Between the upload of the file and the completion of the print, deviations cannot be measured. This is precisely what we want to change with production monitoring.

Our successful prints are based on numerous unit tests and rejected parts. Closing the loop can significantly reduce the time required to produce qualified parts.

How it works

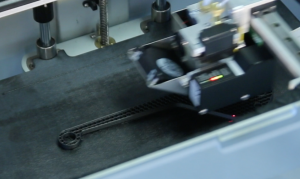

A laser micrometer scans the brake lever.

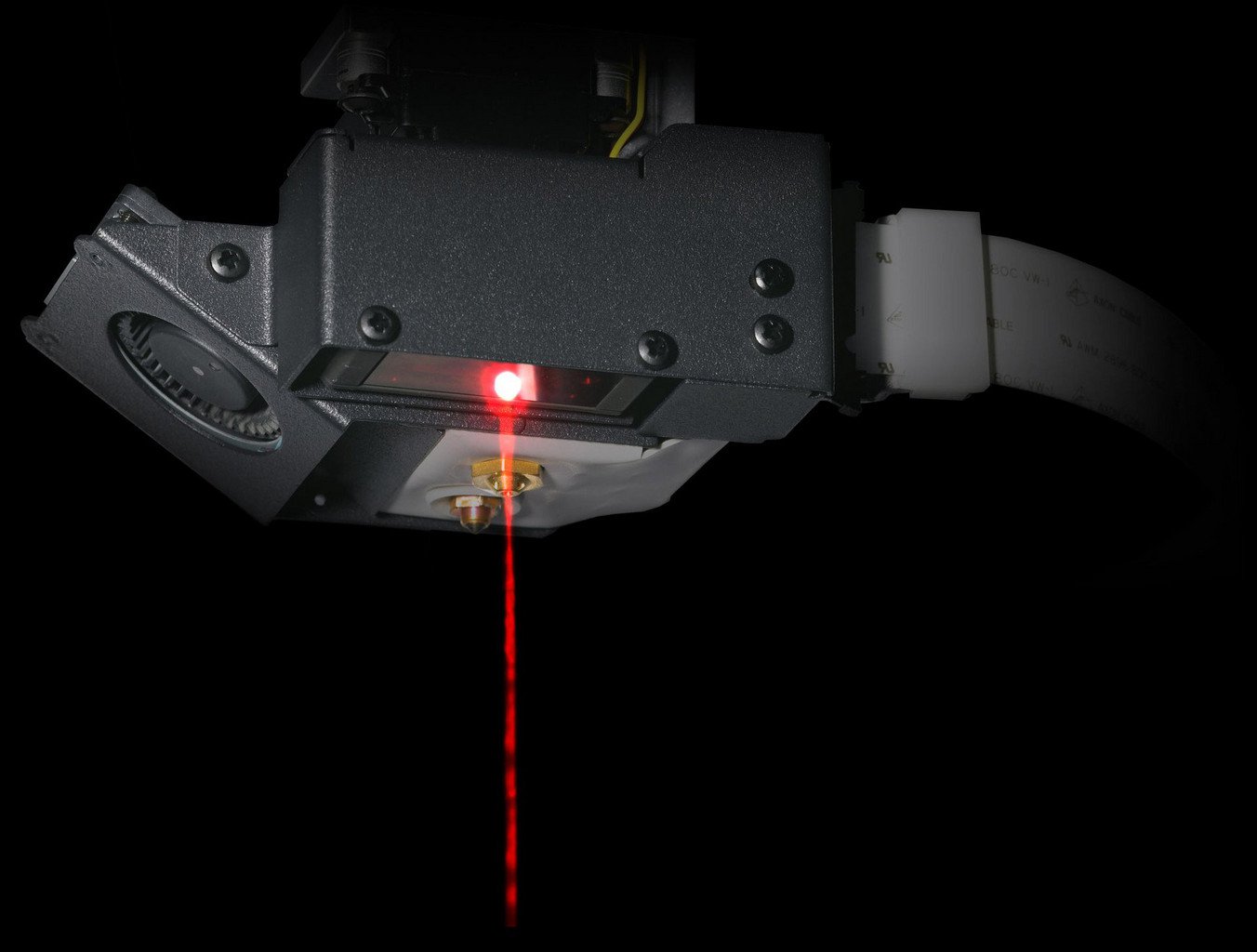

The Mark X takes the first step toward closing the loop in 3D printing. Here's a quick guide on how to use it.

- When uploading a part to Eiger, the user defines the planes to be scanned. The scans vary in time with part size and scan resolution. The result is accurate to within 1 micrometer in the Z-axis and 25-50 micrometers in the XY plane.

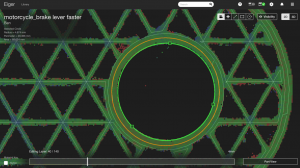

- Once a layer has been scanned, the results are accessible via Eiger, our cloud-based software. The scan itself is color-coded according to the distance from the part to the printer.

- During printing, Eiger allows users to inspect various aspects of the part. Several measurement tools are available, including a circle tool, distance tool, and rectangle tool. These allow tolerance deviations to be quickly and easily measured during printing.

- If the dimensions do not fit, the print can be canceled at any time.

A detailed scan of a recess in a sample part. Three points of the circle to be measured were defined using the circle tool. The dimensions are displayed in the upper left corner.

Since the loop is closed manually, this remains transparent. Errors can be located directly, and the part can be analyzed in the CAD program (e.g. with SOLIDWORKS) can be adapted accordingly. This allows usable parts to be produced faster, more cost-effectively, and more reliably than ever before.

The future of 3D printed parts

The Mark X is transforming 3D printing, but it's still just the first step toward closing the manufacturing loop. Additive manufacturing is designed to be as intelligent, cost-effective, and reliable as possible. The Mark X is fascinating, but in reality, we've only scratched the surface of what's possible. In the coming months, we'll continue to develop the use of the laser, simplify operation, and improve the software. Buying a Mark X isn't just buying a machine. Buying a Mark X is an investment in the future of fully automated 3D printing. We'll continue working to enable an ideal manufacturing world.

Hinterlasse einen Kommentar