This guest post was originally written by Charles Guan. He studied mechanical engineering at MIT and has also taught in the shop floor and design departments. He now works as a consulting engineer. He also builds combat robots. Markforged is sponsoring his participation in BattleBots, ABC's combat robot competition. Check out his Website and Facebook page to.

Combat robots – background knowledge

Bronco, a pneumatic pinball machine in BattleBots (Source: BattleBots).

In the world of combat robots, one mostly sees standard designs. Occasionally, however, unusual robots join the fight. One such example is the "flywheel flipper." Super-fast flipper arms that launch opponents into the air are nothing unusual. They are usually pneumatically powered. This provides a lot of power, but they consume a lot of energy. Even the best flippers run out of energy after just a few good attacks. The electric flywheel flipper combines the high energy density of batteries with the robot's existing kinetic energy.

The energy had to be converted into a form that could be released quickly and in a controlled manner. Reliable switching mechanisms, consistent timing, and progressive acceleration were required, while remaining within budget.

There are only a few examples to choose from. In the 3 to 30 pound weight class, there is a series by Zac O'Donell, including his robot MagneatoDale Heatherington also has some successful designs Among the larger robots, Warrior the scale.

Magneato, a 30-pound pinball machine (source: SPARC Forum).

The Warrior, also a participant of the BattleBots (Source: BattleBots).

The two robots operate according to different concepts. This is an indication of their current state of development. The optimal solution to a problem is adopted by other designers. Therefore, the robots are often similar.

The new weapon system was to consist of two coaxially arranged components to create new strategic capabilities. A 3-pound robot is the right size to manufacture the necessary components with the Mark Two.

Minotaur, another BattleBot with a classic vertical spinner design (Source: BattleBots).

Constructing the 3D-printed gearbox

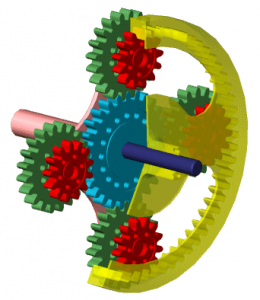

A planetary gear with various connected gears (source: Mathworks).

The biggest challenge is being able to engage and disengage a high gear ratio (20:1 and higher) as needed. A transfer case with a splitter solves this problem. A planetary gear system similar to the Hybrid Synergy Drive developed by Toyota is used.

All robot components must be as small as possible. Nylon would be too flexible for the tiny gear teeth. Onyx is strong enough to withstand the large and spontaneous stresses of combat.

A planetary gear made of onyx. When one of the coaxial large ring gears is stopped, the other rotates.

Arming for robot warfare

The gearbox must be installed into the robot. Here's a diagram of the overall design:

The first design of the combat robot with a spinner and flipper. The two weapons are arranged coaxially, and you can switch from one to the other at will.

The triangular base body eliminates the need for up and down. The robot can be used in both positions equally well. The round, silver part on the left is an aluminum spinner. Cylinder head screws serve as the teeth. The planetary gear is shown in black. If you stop the rotation of one ring, the other spins. The two metal flippers rotate against each other. While one pushes against the ground, the other can lift the opponent into the air.

Some geometric details still need to be refined, but the concept is promising.

The system is demonstrated here:

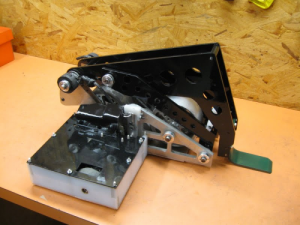

Here are some more pictures of the construction:

The newer 3D printed mechanism from the inside.

The assembled gearbox of the flywheel flipper.

Photos by Charles Guan

This article was originally published on the Markforged blog. Here go to the original article.

Translated by Antje Kasemann

Leave A Comment