Real-World Results: How Manufacturers Are Transforming Their Workflows with 3D Scanning & Printing

Modern manufacturers are already using 3D scanning and printing for manufacturing to cut costs, shorten lead times, and boost flexibility across their supply chains. Discover how real companies are achieving fast, measurable results – and see what’s possible for your business.

Quick ROI Hits – Proven Value in Manufacturing.

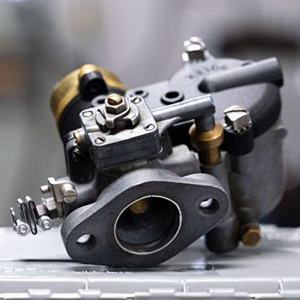

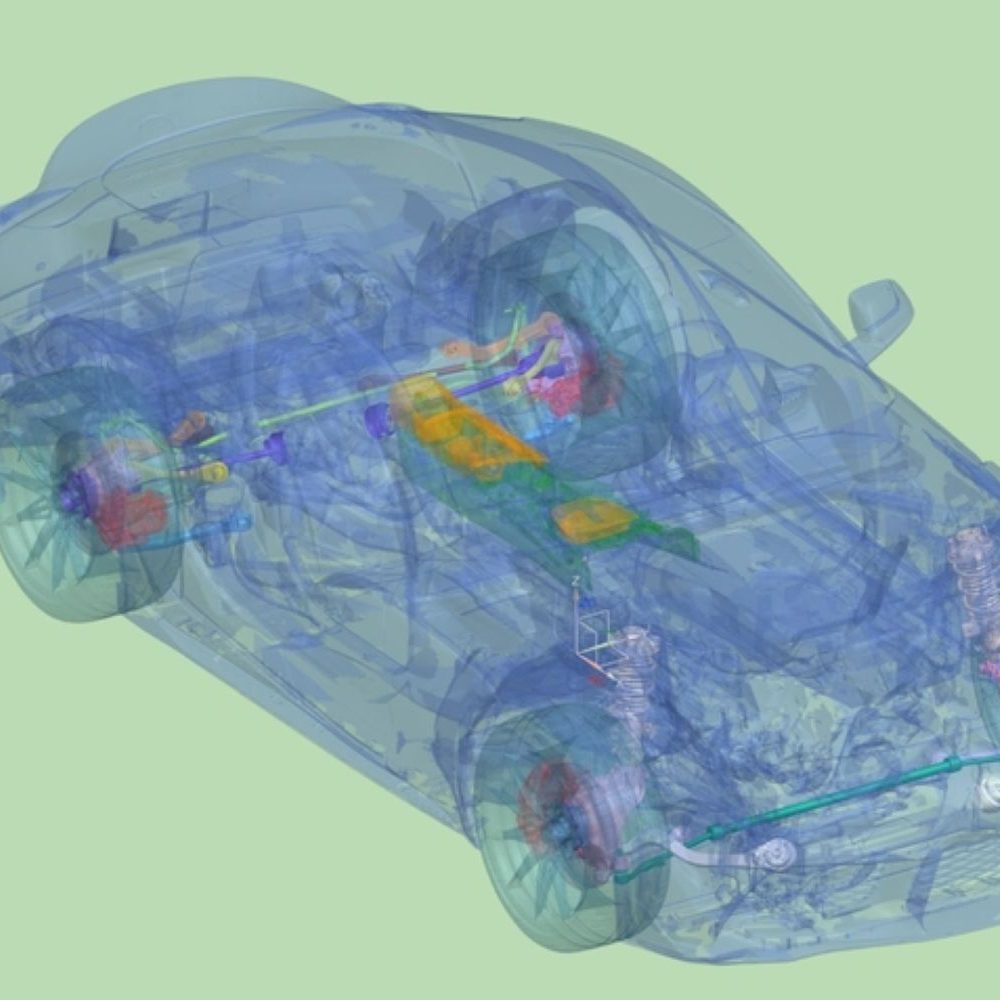

3D scanning and printing are no longer future concepts – they’re proven tools delivering rapid ROI for manufacturers today. By combining precise data capture with strong, lightweight printed parts, companies are transforming their operations.

Typical Results:

-

- Lead times cut by up to 90%

- Tooling costs reduced by 70%

- On-demand, flexible production

These digital manufacturing workflows are helping teams respond faster, iterate more often, and stay ahead of disruption.

Real-World Case Studies

See how leading manufacturers use 3D scanning and printing to achieve remarkable efficiency gains.

Why This Matters – Real ROI, Real Results

The return on investment from 3D scanning and printing for manufacturing is measurable – and fast. Most manufacturers see ROI in less than three months. This shift is part of the wider transformation explored in our article, The Future of Manufacturing – How Scan – Print – Validate is transforming Industry 4.0.

Typical Results

-

-

- 70-90% shorter lead times

- Up to 80% lower part costs

- Faster design iterations

- Reduced supply chain risk

-

Discover What’s Possible for Your Business

Curious how 3D scanning and printing could work in your workflow?

Tell us a little about your application and our experts will recommend the best-fit solution – whether that’s for scanning, printing, or both.

Technology Overview

Trusted by Manufacturers Worldwide

Join the growing number of manufacturers using 3D scanning and printing for manufacturing success.

-

- UK-based support, training, and service

- Proven case studies across aerospace, automotive, and tooling

- Trusted by industry leaders