3D Printed BattleBots Quantum

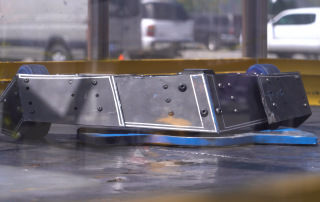

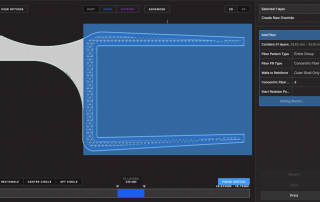

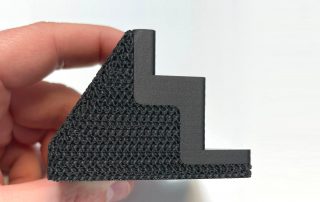

3D Printed BattleBots Quantum [Video] This 3D printed BattleBot is Quantum - created by the same team behind Robot Wars, this is a super high power crushing jaw robot with 30,000 lbs of force behind it's teeth.Team Quantum have made excellent use of Markforged 3D printers, replacing critical structural components of their battle [...]