Ready-to-Use Parts over night

No limitations in manufacturing or design

Find a strong ROI

Print stronger than aluminium

Can 3D printed parts really be stronger and more cost effective than Aluminium?

Why you need a composite 3D printer!

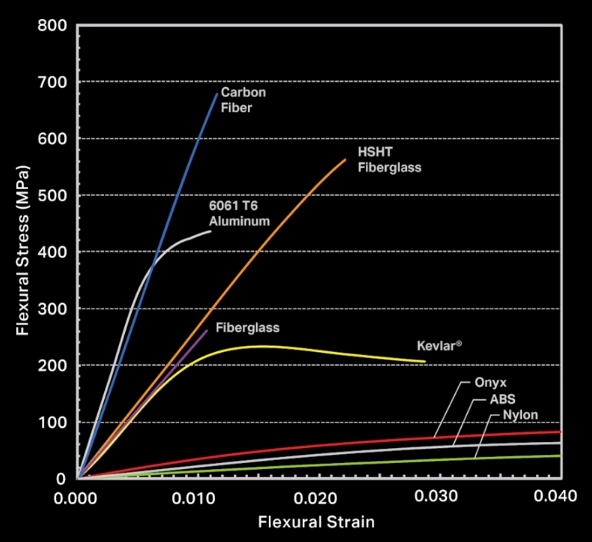

The Markforged print materials include Onyx, Nylon and Fibre Reinforced Plastics such as Carbon Fibre, Kevlar and Fibreglass. The chart to the right shows how these compare with Aluminium for strength, toughness, stiffness and environmental resistance.

Carbon has the highest tensile strength, but the fiber is separated after about 680 MPa. Kevlar, however, has a significantly lower tensile strength of about 200 MPa, but can stretch very strong. Aluminum 6061-T6 fails according to the diagram much earlier than the carbon fiber. The HSHT glass fiber is astonishingly powerful, as it can not only absorb high strain and strain loads, but is also used without any problems in applications up to 145 ° C.

But it’s not just about being able to print stronger but also more cost effectively using 3D printing technology and Fibre reinforced plastics. Meanwhile 3D printing is advancing into the realm of production, both in terms of work-holding and custom end-use parts. So whilst the value of a printer didn’t used to be blindingly apparent at first, when you run the calculations now, it tells a different story.

Learn more about applications with plastic printing with continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.