The EIGER-Software 3D printing with high-end printing materials and endless fibres

Try the Eiger 3D printing software today!

The Markforged Eiger software is powerful and very easy to use. Your components can be quickly optimized with the right settings and fibre orientations to optimally design your component for your application.

You can easily load the component created on the CAD program as an STL file via the browser (Google Chrome) into the cloud-based Eiger software. There you can manage and catalog your files.

After uploading the STL file, you can optimize it for your application with just a few mouse clicks. e.g. Enlarge wall thicknesses, scale, adjust fill density, select honeycomb structure, adjust support structure, etc.

In the next step, you insert the fibre into the component, it is freely selectable in which layers the fibre should be inserted. There are 4 adjustable fibre types to choose from Carbon Fibre, Fibre Glass, High Strength High Temp Fibre Glass and Kevlar. You can adjust the amount of fibre in the part to suit the correct application.

The printing process can be paused to embed components in the print. Such as nuts, bolts and magnets into your component. When printing with supports turned on , the support structure is generated automatically. When printing parts with an angle over a 45 degree supports will be required.

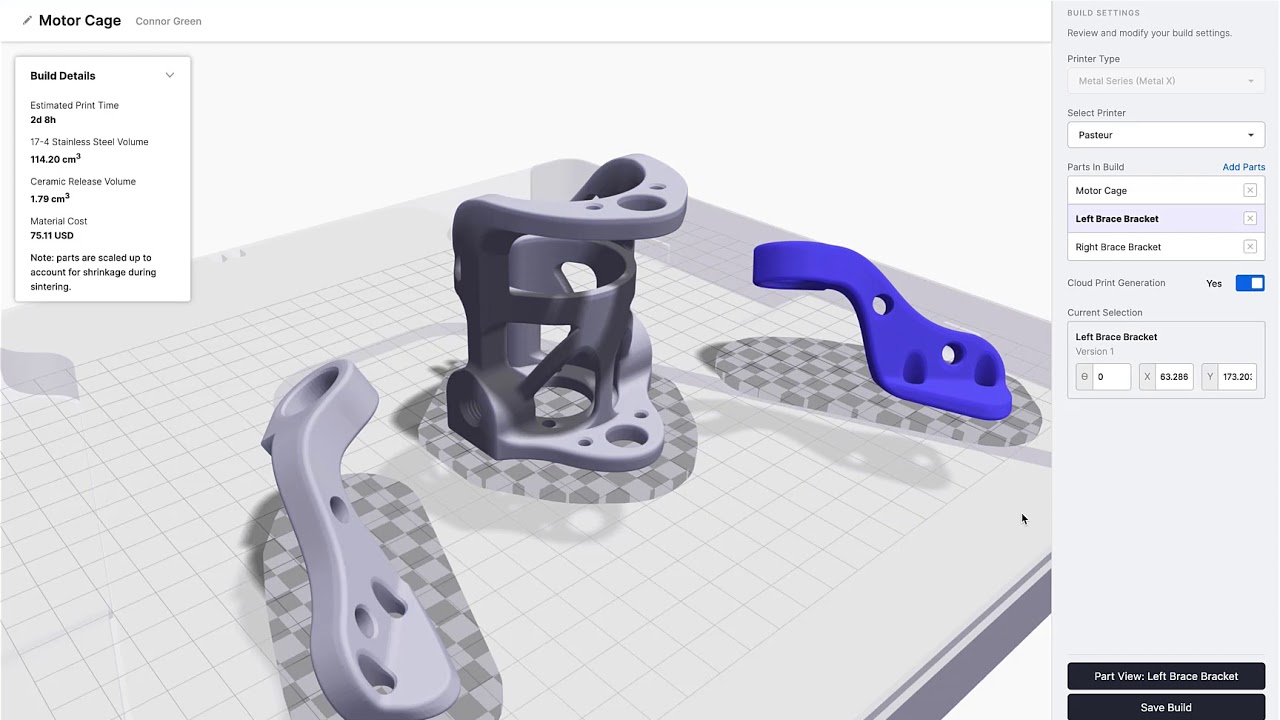

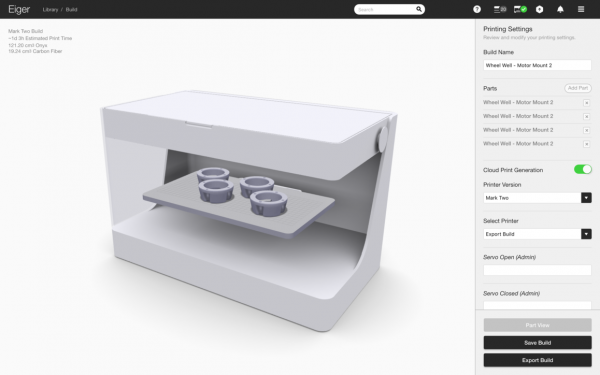

Production-ready printer management

Eiger adds selective fiber reinforcement to your part for 3D printing on a Markforged machine. Thanks to powerful fiber routing and slicing intelligence, the software is easy for any technician to use and allows intervention when needed. The free, cloud-based Eiger platform is suitable for any size printer network, whether you have one or a hundred Markforged 3D printers.

Advantages of the Eiger Software

- Intelligent and very user-friendly Software (Plug & Play Principle)

- Manage and catalog components by project and user

- Free add-on for additional users

- Integrated support with detailed help and video tutorials

- No update or unnecessary disk space required because cloud-based

- Anytime access and login because cloud based with Google Chrome browser

Settings for optimizing the component

- Name of component

- Scaling

- Placement of the component

- Choice of Fibre types (Carbon, Kevlar, Fibre glass, HSHT Fibre glass)

- Selectable fibre fill type (Concentric, Isotropic, Full Fill)

- Pre-settable number of fibre layers

- Adjustable number of fibre rings on the surface of the component

- Automatically generated support material for overhangs

- Mode for fine contours

- Anchor option for better hold on the site

- Metric or inches

- Printable layer height

- Part Fill Type (Hexagonal, Triangular, Full Fill)

- Part filling density (adjustable from 0% to 100%)

- Adjustable floor and ceiling layer of the component

- Adjustable number of wall layers

- Add notes and keywords for cataloging

Settings for inserting the continuous fibre in the component

- View in 2D and 3D

- You can choose in which layers a fibre should be inserted

- Freely selectable according to which fibre type is to be inserted (Concentric, Isotropic, Full Fill)

- Freely selectable how many fibre rings should be placed on the surface of the component

- For Full Fibre Fill, an angle of the inserted fibre can be specified

- Printing can be stopped (for example, for inserts such as nuts, bolts, magnets)

- Display of printing time and material consumption of plastic and fibre

- Hide individual component sections

Print Mode

- Positioning the component on the build platform

- Adding other parts

- Save printing

- Downloading parts and printing

- Monitoring print progress online

Learn more about applications with plastic printing with continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.