3D Printed BattleBots Quantum

3D Printed BattleBots Quantum [Video] This 3D printed[...]

3D Printed BattleBots: Valkyrie vs Quantum

3D Printed BattleBots [Video] Valkyrie vs Quantum [...]

Can you break a 3D printed part?

Can you break a 3D printed part? [Video] [...]

MACH 2024 Wrap Up!

MACH 2024 Wrap Up! That's a wrap![...]

Jet Dragster Racing [Video] with 3D Printed Parts

Jet Dragster Racing [Video] with 3D Printed Parts [...]

Hollywood Propmaster [Video] 3D Printing with Markforged

Hollywood Propmaster [Video] 3D Printing with Markforged Thingergy[...]

BattleBots Valkyrie [Video] Using 3D Printed Parts

BattleBots Valkyrie [Video] Using 3D Printed Parts [...]

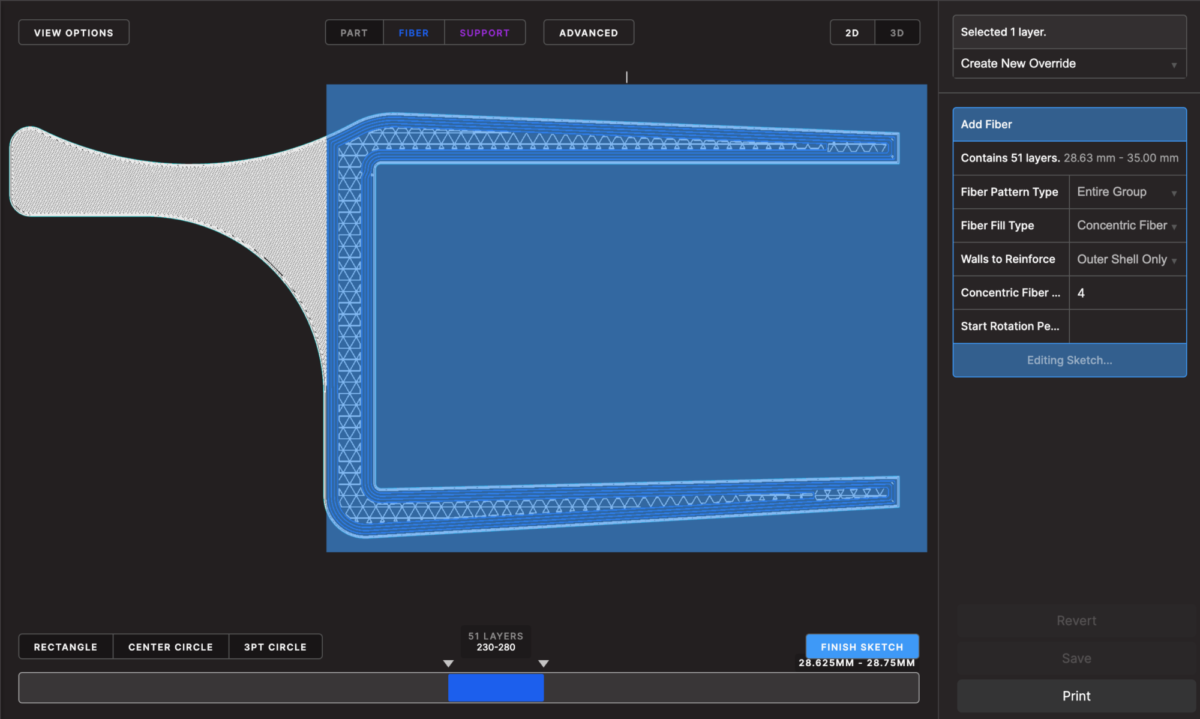

Fibre Override Sketching – New Eiger Tool

Fibre Override Sketching - New Eiger Tool [...]

Mark3D UK is expanding – new office

Mark3D UK is expanding - new office [...]