Markforged FX20

The Beast of Additive Manufacturing

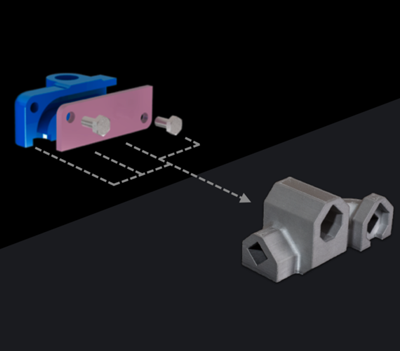

The FX20 will be the largest, fastest and most sophisticated industrial 3D printer Markforged has ever developed. It has a new high-temperature system that is suitable for 3D printing of thermoplastics reinforced with continuous fibers. Printing high-strength, precise, and high-performance parts makes the FX20 ideal for industries such as aerospace, defense, automotive, and oil and gas.

Even stronger components with ULTEMTM 9085

The Markforged FX20 is the first printer in the Markforged family to print the new ULTEM TM9085 material. The material is characterised by its high resistance to heat and chemicals and also has the highest tensile and flexural strength. In addition, the conventional materials such as Onyx, Onyx FR, Onyx ESD, Nylon White and a support material for ULTEM TM 9085 the ULTEM TM Support can be printed.

Request a demo!

Feel the strength of continuous fibre for yourself.

Larger build volume for your applications

An even larger and heated installation space ensures components of the highest quality.

Touchscreen Interface

The Markforged FX20 has an integrated touch screen that allows you to easily connect to Wi-Fi, start prints and manage your 3D printer.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.