The Digital Forge:

Industrial 3D printing for your manufacturing – more independence, availability and innovation in your production processes.

Markforged 3D Printers allow you to print extremely stable and high-quality, three-dimensional parts – in the shortest possible time and at a fraction of the cost and with maximum stability! Get to know the new possibilities and benefits of professional Additive Manufacturing.

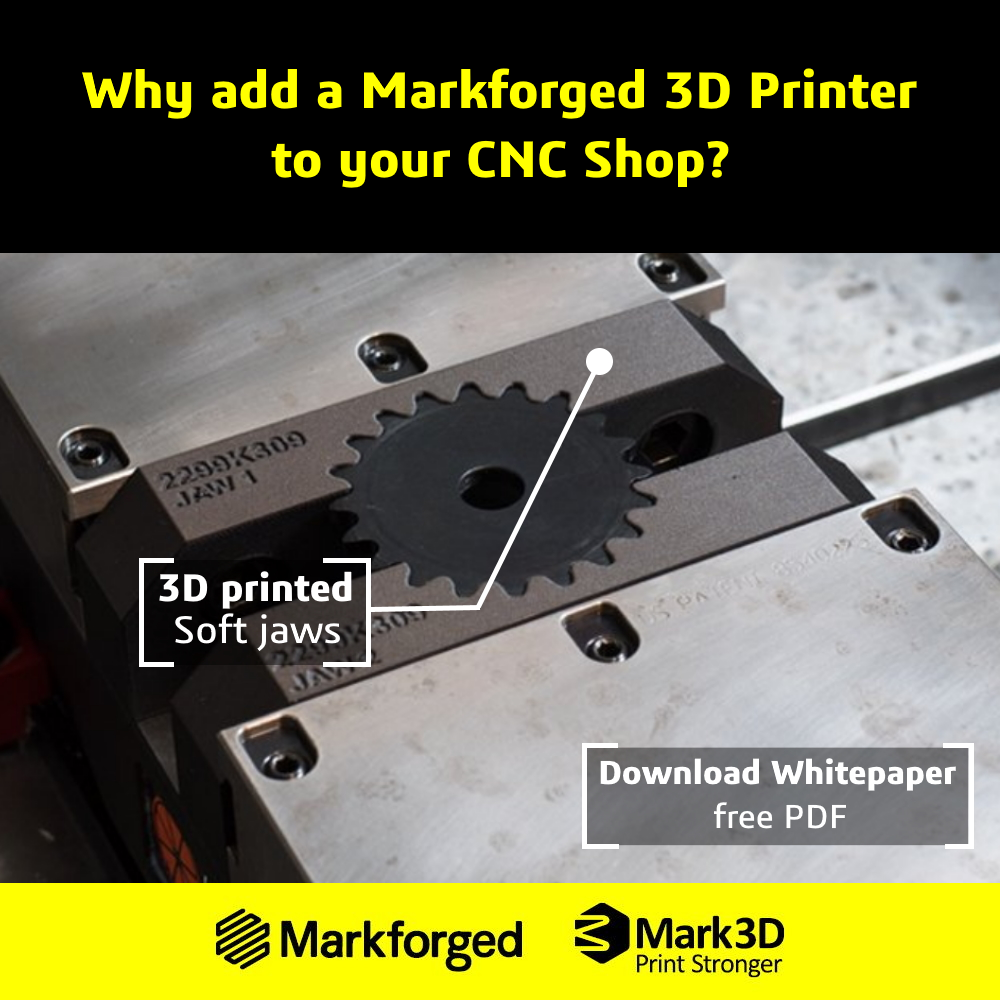

Why add a Markforged 3D Printer to your CNC Shop?

If you have a shop full of CNC machines there’s a clear, distinct benefit to be gained by adding a 3D printer to your portfolio of machines. The ROI is quick, readily found and sustainable.

On average 3D printing is 10x less expensive than CNC machining, so here are 15 reasons, why you should add a 3D printer to your CNC shop.

Also join our webinar!

3D printing as a useful manufacturing supplement!

Economical 3D printing with advanced materials such as Onyx or Carbon continuous fibre reinforcement and metal. Components made of Onyx in combination with a Carbon continuous fiber achieve strengths of aluminium. You can therefore produce highly stable components that you previously had to machine but did not want to machine.

The future of manufacturing is now

In 2014, Markforged introduced the world’s first and only carbon fibre 3D printer. More than 1000 customers later, that mission hasn’t changed: To give every engineer the ability to hold 3D printed parts with extremely high strength in their hands on the same day. Because with a Markforged 3D printer, you can get your parts even faster and more innovatively. Whether made of onyx with a carbon continuous fibre, stainless steel or 11 other printing materials. For applications that need to be feather-light, durable or printed with extremely high strength. 3D printing is not a technology of the future. 3D printing is already a fully-fledged manufacturing technology.

Applications for Markforged 3D Printers

Jigs, Fixtures & Tooling

From custom soft jaws for work-holding to alignment jigs for welding, the applications for Markforged 3D Printers are endless. With this in mind you can significantly improve many of the behind-the-scenes tasks associated with manufacturing and fabrication. Furthermore you will experience shorter lead times, increased machine bandwidth and substantially reduce your manufacturing costs. Complementing your manufacturing facility with a Markforged printer is comparatively easy and very cost-effective.

End Use Parts

3D printing is now a viable alternative for manufacturing end use parts. It proves to be a very cost-effective solution when compared to traditional low-volume production techniques. For example you can make end-use parts that are very strong, with excellent surface finish and high accuracy on demand. As a result this will substantially reduce your companies manufacturing costs and hence improve your bottom line.

Prototypes

It’s now possible, using the prototype you created for form and fit, to immediately test for function. Because The unique range of Markforged materials aren’t just strong, they look good too. Therefore if your prototype works you can leave it in place and get on with something else. Subsequently you’ll dramatically shorten development cycles, save money on materials and carry a zero spares inventory.

The range of Markforged 3D Printers

With the Markforged desktop range you can 3D print stronger components from your office. The Desktop Series includes the Markforged Onyx One, Onyx Pro and the Mark Two 3D Printer! The Mark Two is a Carbon fiber 3D Printer which offers you industrial grade hardware, cloud managed software and engineering grade materials combine to allow you to print light, strong replacements for machined aluminum. Now your parts can be ready the same-day, for a fraction of the price. Often many peoples first venture in to 3D printing, the desktop range is specifically designed for engineers. They find new ways to design and make their components very quickly due to the short learning curve. However, it doesn’t stop there, the works engineers and maintenance teams find many different uses for it too. What could you do with a 3D printer from Markforged?

The Markforged industrial series of machines make incredibly strong, high precision components. The large working space on all industrial series printers is ideal for robotics, automotive parts, prototype models and prosthetics. With a layer thickness down to 0.05 mm, your prints receive a perfect surface finish and the look and feel of an injection moulded component. Built with quality, accuracy and reliability in mind the industrial series machines use the highest quality components. They are manufactured to close tolerances and enjoy the added benefit of laser scanning for part accuracy. Many companies that have made their initial investment in desktop machines choose to further invest in the industrial series.

Safe, reliable and affordable 3D metal printing from Markforged. The Metal X significantly accelerates your design innovation and delivers metal components overnight. Forget manufacturing from the 20th century and print everything, such as industrial spare parts, injection moulds, product samples and working prototypes. Now metal printing has become a reality you will begin to see more components being manufactured as single body parts. Markforged have made sure it’s easy to remove the support structure too, so there’s no hazardous secondary processes to contend with. Sold as a bundle the Metal X, the wash station and the sintering oven offer great value for money in today’s market

Mark3D your Markforged Reseller for Europe and the UK

Mark3D is your UK partner for Markforged high-end 3D printers, materials, software, spares, training and consultancy. We will help you to find the right solution for your application from the range of composite and metal Markforged 3D printers.

Markforged are on a mission to bring industrial 3D printing to the point of need, so that supply chains can become resilient. This is being done by building The Digital Forge, the world’s most reliable, intelligent, and easy-to-use additive manufacturing platform.

Mark3D UK help businesses evaluate, develop and adopt Additive Manufacturing applications into their production processes in a variety of industries covering Aerospace, Automotive, Consumer Products, Oil and Gas, General Manufacturing. Military and more.