Digital Source

Unlimited Spare Parts in One Click

Digital Source

Unlimited Spare Parts in One Click

Consistent, factory-ready component quality.

Software, printers and materials working together seamlessly as a unified platform. The Digital Forge is specifically designed to deliver unrivalled quality and consistency – anywhere in the world.

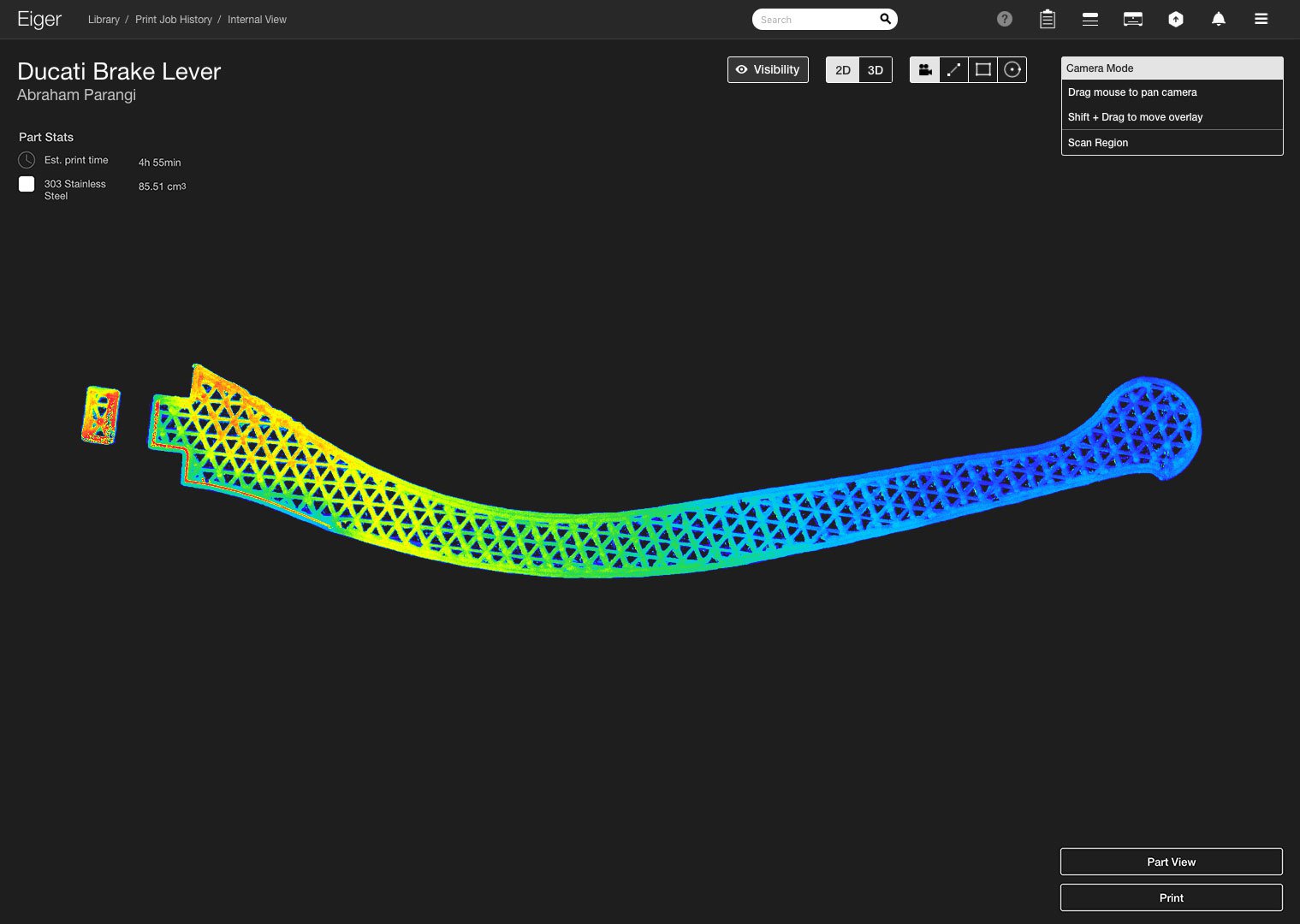

Licensed digital components, straight from the source.

Manufacturers upload their component designs to a digital warehouse where customers can find and purchase licenses to 3D print parts.

Immediate on-site printing or outsourcing for flexible processing.

Customers can print critical components on-site the same day, or access a list of verified print providers to order printed parts at scale.

No back and forth when purchasing.

No shipping. No delays in customs clearance. Just press print.

Reduce paperwork and time-consuming processes.

Simpler manufacturing processes improve employee productivity and customer satisfaction.

Say goodbye to storage costs.

Improve profitability by reducing waste from overproduction, storage costs, shipping and taxes.

How does Digital Source work?

Upload your part and then set the printing process requirements. Approved customers can search digital catalogs and print components, but they cannot download, modify or recreate the design.

Manufacturers get paid for their part designs and customers get the flexibility to print parts when and where they are needed.

“Time has a very high monetary value to us – a belt failure in one of our factories is a big deal, but a failed turbine can cost even more. If we can access and print the part we need, we can change the equipment or turbine much faster and get back into operation.”

Learn more about 3D printing with continuous fibres!

Which continuous fibre is suitable for which applications? How do I properly design for filament 3D printing? What do users say about it and where can I find more information? – You’ve come to the right place! The options below will take you directly to the right answers.

Have questions, or need a demonstration or quote for a Markforged 3D Printer?

Contact us now!

![]() Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Telefon: 07361 63396-00 E-Mail: markforged@mark3d.de

Um mit uns in Kontakt zu treten, füllen Sie bitte unser sicheres Formular aus.